BSE4535 Semi-Auto PP/PE Film Heat Shrink Packaging Machine, film plastic bottle wrapper, heat shrink packing machine

♣Equipment Introduction♣

Shrink Packaging is the international market, more advanced packaging methods. It is the use of shrink-wrapped in the product or packaging outside, and then heated to shrink packaging products and bind tightly or equipment parts,

it shows that the sales of goods in order to increase the sense of beauty and value; Meanwhile, The Shrink packaging machine after items can be sealed, moisture, pollution prevention and protection of goods from external shocks, has a certain buffer,

in addition, can reduce the products are demolished, the possibility of theft ; shrink film shrinks produce a certain tension, it can a group of items to be packaged bind tightly rope tied to play the role, especially for multi- items in the collection and tray packaging, so the product can be widely used in a variety of small product packaging. Widely used in food, beverage, pharmaceutical, cosmetic, hardware, wood products, stationery, printing products, plastic products, glass products, electronic components and other products a single, aggregated or combined packaging.

♣Equipment Features♣

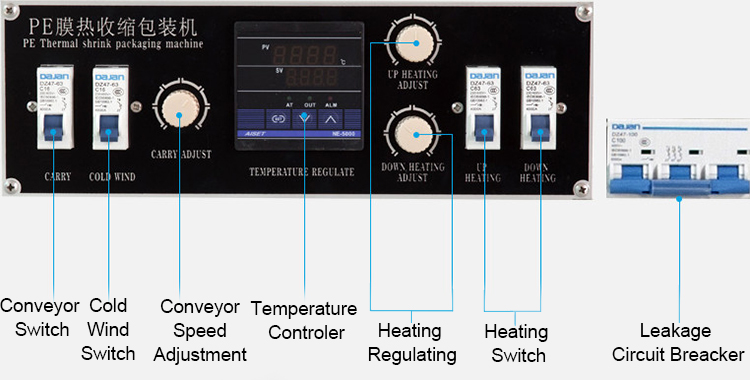

1: The machine adopts digital temperature controller, which makes operation easier.

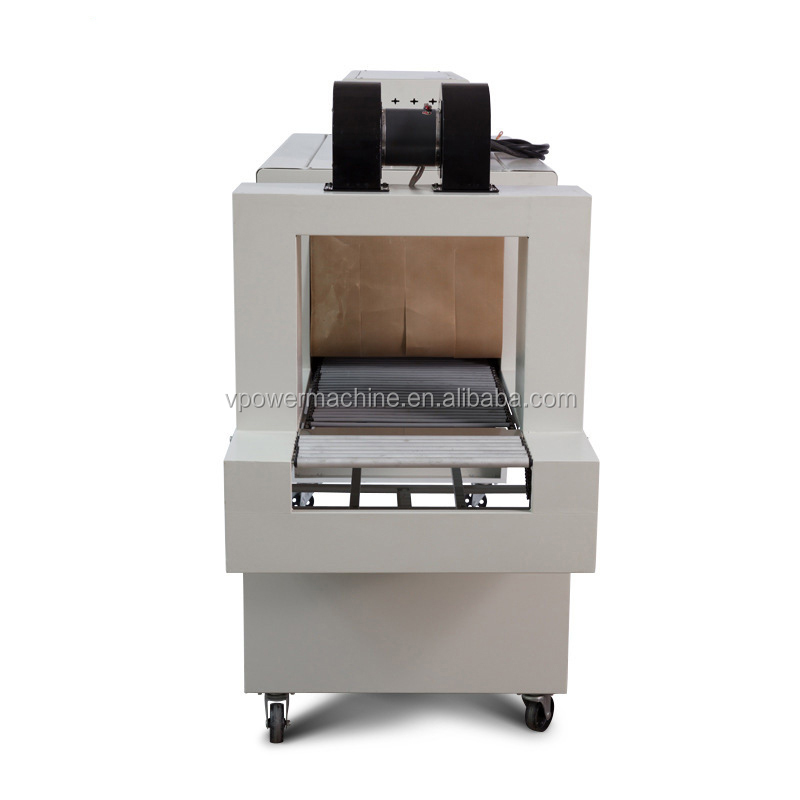

2: The powerful fans inside the tunnel make the air heating very equally.

3: Adopts intro- Quartz heating tube to reduce the power consumption

4: Conveyor Roller uses the solid roller with silicone outer, hence the machine can load large subject without burning the shrink film.

5: Reinforced conveyor motor ensures steady transport and the speed of the conveyor is adjustable.

6: There are shrinking tubes on the top, bottom, and sides of the shrinking room.

7: Supercooling system cools the packing and makes the figuration perfectly.

8: There are two different types of the conveyor to choose from, roller, and net.

♣Equipment Parameters♣

|

Model |

BSE4535 |

BSE5038 |

BSE6040 |

|

Power supply |

3phase 220V/380-460V 50-60HZ |

||

|

Heater power |

18KW Adjuster |

19KW Adjuster |

20KW Adjuster |

|

Conveyer speed |

0-10m/minute |

||

|

Tunnel size(L*W*H) |

1200*450*350MM |

1200*500*380MM |

1800*600*400MM |

|

Conveyer loading |

25KGS MAX. |

25KGS MAX. |

25KGS MAX. |

|

Machine size |

2200*730*1440MM |

2200*780*1470MM |

2800*880*1570MM |

|

Machine weight |

220KG |

250KG |

285KG |

Reviews

There are no reviews yet.