Products Description

1. The equipment composition mainly adopts imported original parts, which can complete cutting wires, stripping, terminal crimping, etc., with precise action, simple operation and stable performance.

2. The tool post adopts the structure of servo and screw rod, the depth of the cutting knife is adjusted by computer, and the cutting is accurate

3. The whole stripping length is directly set by the touch menu panel. Fast technical performance adjustment, short adjustment time, simple operation

4 Suitable for horizontal and straight OTP molds.

2. The tool post adopts the structure of servo and screw rod, the depth of the cutting knife is adjusted by computer, and the cutting is accurate

3. The whole stripping length is directly set by the touch menu panel. Fast technical performance adjustment, short adjustment time, simple operation

4 Suitable for horizontal and straight OTP molds.

|

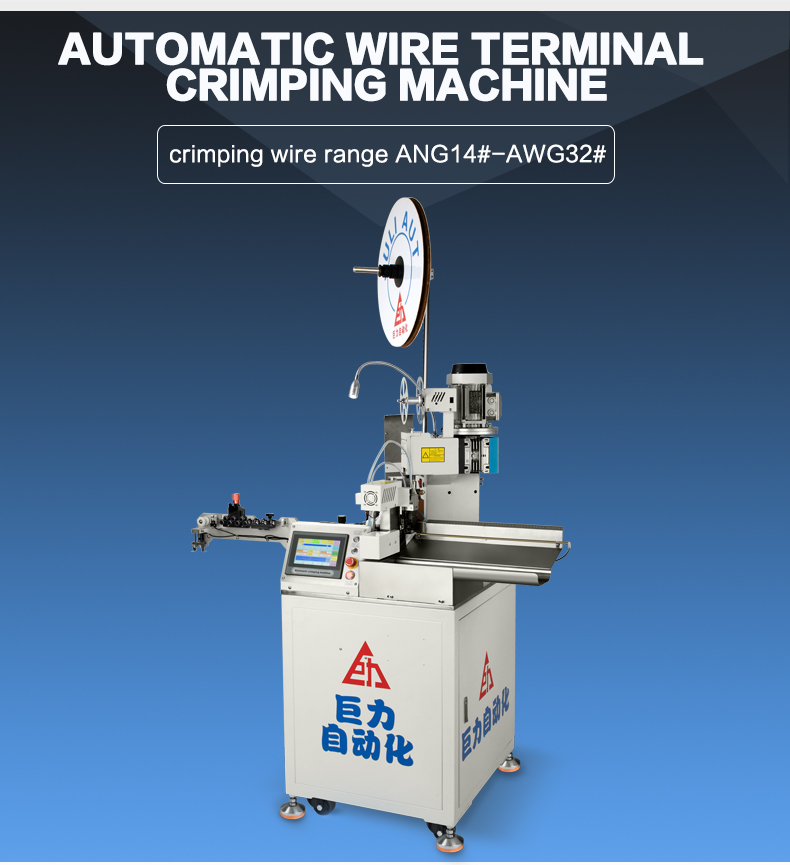

Full automatic single-end otp applicator terminal crimping machine

|

||

|

Model

|

BG-121A automatic terminal crimping machine

|

|

|

Display

|

LED touch screen

|

|

|

Function

|

single crimping, single stripping and twisting; can be used as wire cutting machine

|

|

|

Crimping power

|

2 Ton

|

|

|

Wire diameter

|

AWG14# -32#

|

|

|

Stripping length

|

0 – 13mm

|

|

|

Cutting length

|

30 mm- 9999mm( 8-9999mm without twisting) according to wire type

|

|

|

Cutting accuracy

|

0.02*L ( L is cutting length)

|

|

|

Twisting length

|

1-13mm according to wire type

|

|

|

Blade material

|

Imported HSS; other quality material optional

|

|

|

Air pressure

|

0.5 – 0.7 Mpa

|

|

|

Efficiency

|

4500pcs / hour

|

|

|

Product dimensions

|

L600 * W700 * H1500mm

|

|

|

Weight

|

220KG

|

|

|

Detection device

|

wire check; wire tie check; wire crimping check

|

|

|

Remark

|

Special blade need customization with wire samples

|

|

|

Prodcut configuration list

|

||

|

Product name

|

Brand

|

|

|

Pneumatic component

|

SMC

|

|

|

Motor

|

Stepper motor + closed loop motor + frequency change motor

|

|

|

Driver

|

Yakon + Panosonic

|

|

|

Ball Screw

|

TBI HIWIN

|

|

|

Sliding rail

|

HIWIN

|

|

|

Touch screen

|

SIMATIC

|

|

|

Motherboard

|

programmable card or PLC

|

|

|

Belt

|

American Gates

|

|

|

Synchronous wheel

|

Aluminium synchronous wheel + Beryllium copper synchronous wheel

|

|

|

Bearing

|

Japan NSK bearing

|

|

|

Substrate

|

CNC machining steel + substrate

|

|

|

Rubber wheel

|

Aluminium core resin wrapped / knurled metal wheel

|

|

|

Blade

|

Titanium plating HSS

|

|

|

Main power supply component

|

Meanwell

|

|

Packaging & Shipping

Company Information

Certifications

FAQ

1. Why choose us?

We provide overall solutions for processing equipment. Our standard equipment is very complete, all are in stock and can be shipped quickly. We have our own equipment factory, which can lightly customize equipment according to customer requirements, such as ordering different appearances and brands for agents, and non-standard equipment according to customer requirements.

2. Should I worry about the quality?

Before delivery, we do test the machine working condition for you.

Take a video of the normal operation of the machine to you, and then confirm the delivery

Take a video of the normal operation of the machine to you, and then confirm the delivery

3.How can I know your machine is designed for my product?

You tell us the specific parameters of your product, or you can send us samples of your product and we test it on machine.

Video for you to make samples

Video for you to make samples

4. How to operate the equipment?

My friend, don’t worry about it, we have made vedio for you, it will show you how to do it step by step. Contact our engineers at any time when you don’t understand, support video and telephone communication

5.When the machine can’t work well,What should I do?

The Engineer is online for 24-hours, they can check the problems and then give you solution way very soon. Please rest assured that manual will be offered along with machine,ensuring you can operate the machine easily.

Reviews

There are no reviews yet.