Best Value Small Network Cable Bottle Matic Flag Large Format Applicator Asset Labelling Machine

Best Value Small Network Cable Bottle Matic Flag Large Format Applicator Asset Labelling Machine

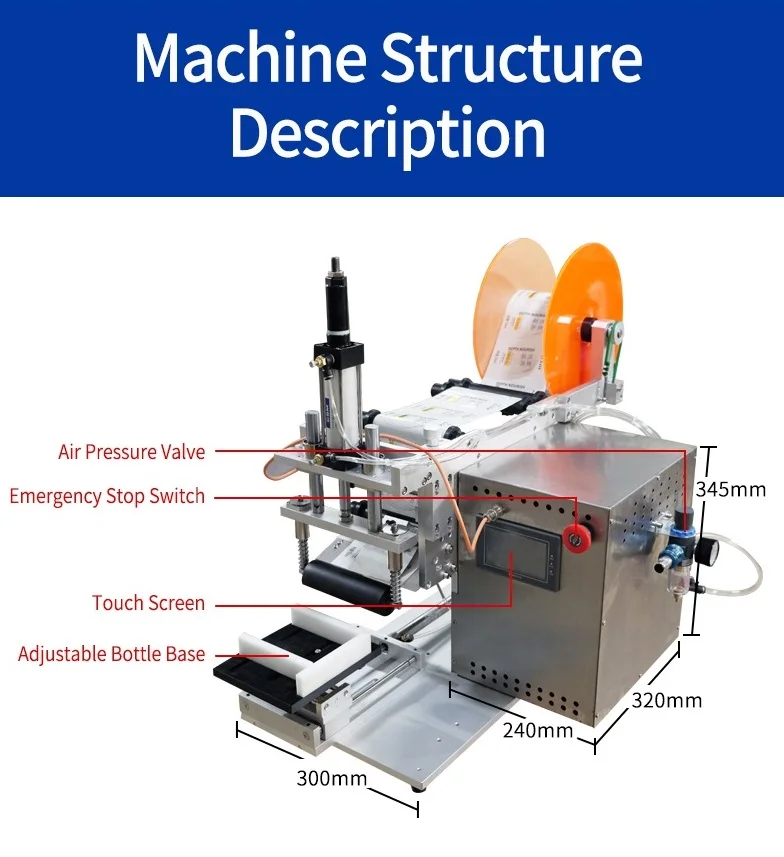

| Label Length | 10mm ~ 340mm

(customized)

|

Label Width |

5mm ~ 120mm (customized) |

| Product Size |

L: 20mm ~ 200mm H: 20mm ~ 180mm

(customized)

|

Standard Labels Roll Outer Diameter |

Φ280mm |

| Labeling Speed | 5-30 pcs / min | Standard Labels Roll Inner Diameter |

Φ15mm ~ Φ76mm |

| Labeling Accuracy | ± 1mm (excluding product and label errors) | Speed of Labeling Head |

5 ~ 45m / min |

| Air Pressure | 0.4-0.6mpa | Machine Net Weight | about 50kg |

| Voltage |

Single Phase 50-60hz |

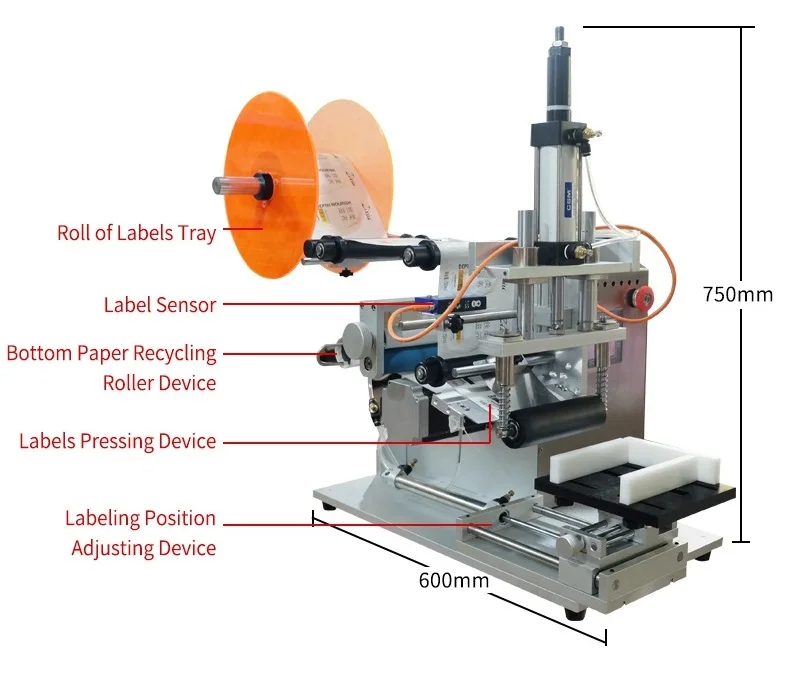

Machine Dimensions (L × W × H) |

600*500*750mm |

♦ Machine technical parameter above is our standard model, the machine can be made based on your products and your requirements.

Best Value Small Network Cable Bottle Matic Flag Large Format Applicator Asset Labelling Machine

Features:

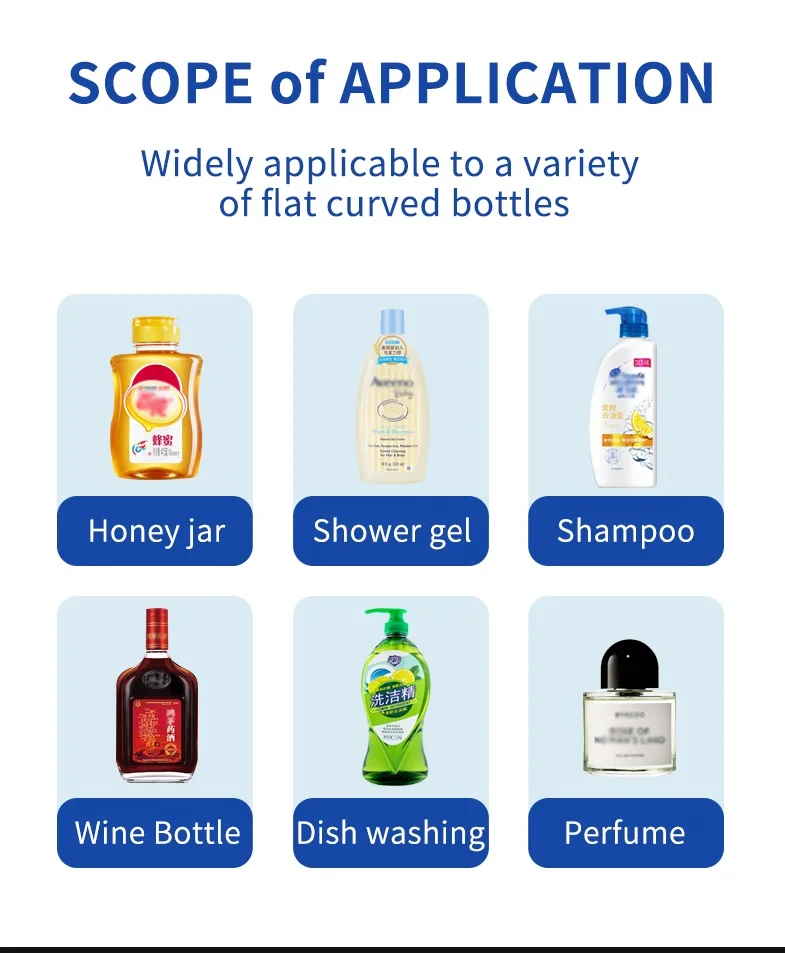

1. The Semi Automatic Flat Surface Stickers Labeling machine is suitable for self-adhesive sticker labeling to flat and square bottles, jars, and cans.

The

Semi Automatic Flat Surface Stickers Labeling machine

has

Intelligent control, automatic photoelectric tracking

, no labeling, automatic calibration without the label, and automatic label detection function to avoid wasting and missing labels.

7. The Semi Automatic Flat Surface Stickers Labeling machine will be offered a 2 whole years warranty after you get the machine, and after-sales service and technical support will be provided to you forever.

Best Value Small Network Cable Bottle Matic Flag Large Format Applicator Asset Labelling Machine

♥ Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

♥ Applicable products: bottles between 20mm ~ 200mm L X 20mm ~ 180mm H.

♥ Application industry: widely used in food, toys, daily chemicals, and other industries.

♥ Application examples: disinfection water bottle labeling, gel water double labeling, wine bottle positive labeling, disinfecting water, and other industries, etc.

◊ Optional ribbon coding and inkjet printers can be used to print the production date and batch number information on the label to achieve labeling-coding integration.

Reviews

There are no reviews yet.