Diesel electric Hay and straw baling machine grass baler wrapping machine mini silage round packing machine

Description of straw silage baler wrapper machine

This silage baling machine is a fully-automatic product, it can match with 5.5kw motor. and operating speed can reach 60-70bundles/h. There are 2-4 coated layer, and bale density is 450kg/m3. Round shape with film has long storage time that is useful for feeding animals. Hay and straw baler machine is suitable for nearly all kinds of silage,fresh or dry straws of wheat, rice, soybean, corn, etc.

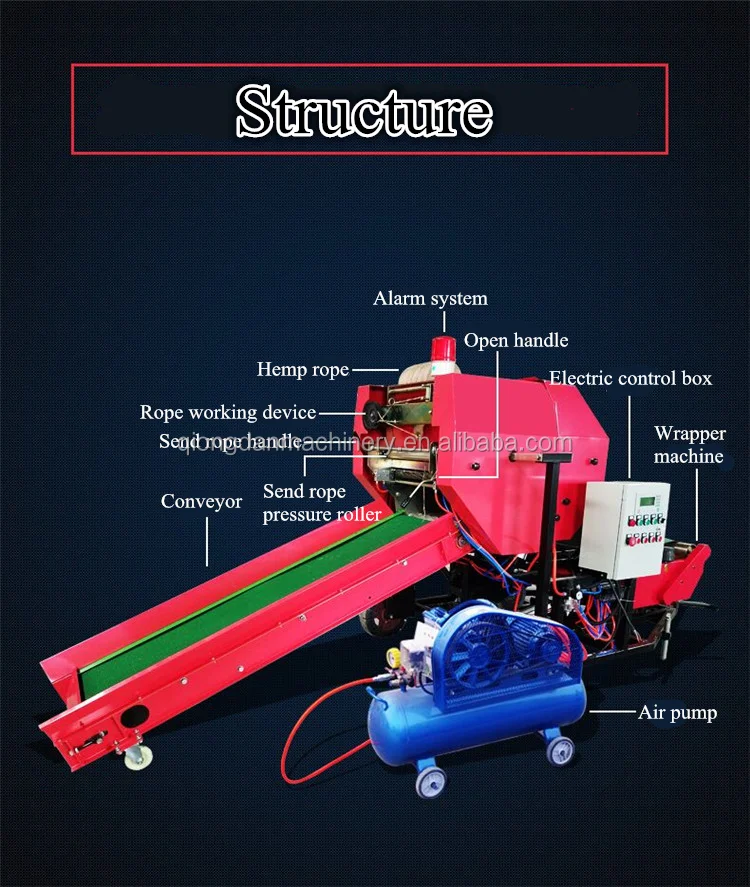

Structure of straw silage baler wrapper machine

Parameter of straw silage baler wrapper machine

| Model | QDDK-1 | QDDK-2 |

| Power | 5.5+0.55kw | 5.5+0.55kw |

| Capacity | 3-5t/h | 4-6t/h |

| Baler size | 550*520mm | 550*520mm |

| Bale size | 65-75kg | 65-75kg |

| Film layer | 2-4 layer | 2-4 layer |

| Wrapper efficiency | 18s/2 layer; 24s/3 layer; 32s/4 layer | 18s/2 layer; 24s/3 layer; 32s/4 layer |

| Machine size | 2200*1500*1500mm | 2400*1500*1650mm |

| Weight | 750kg | 800kg |

Advantages of straw silage baler wrapper machine

1.There is no any influence on wrapped feed even they are exposed in the weather and it can be stacked in the open air for 2 or 3 years.

2.The machine is equipped with a control cabinet and warning light,so the operation is pretty safe and easy.

3.The wrapped feed has high quality and the utilization of it can reach 98%.

Crusher part

The silage or grass are smashed by a smashing part, which destroys the hard stem segments on the surface of the straw by crushing, slitting, squeezing them. Finally, it processes the straw which cannot be directly eaten by the livestock into filamentous type. Such forage can keep its original nutrients that is easy to digest and absorb for livestock. Cattle and sheep like this kind of forge very much. The straw after smashing is easy to bundle, improving the efficiency of fermentation and decomposition of crude fiber and improving palatability.

Baling part

The forage is fed into the working chamber of the baler quickly, uniformly and evenly for compression. When the weight of each bundle reaches about 80kg.When the signal wheel rotates at a constant speed, the winding clutch handle can be pulled and the fine rope can be used for baling.

After baling,the rope is cut, and user starts up the opening handle to make the bundles come out. In this way, the bundling process is completed.

Wrapping part

The bales are placed on the two parallel belts of the wrapping machine, and the wrapping switch drives the bales by rotating frame to rotate. The bales stretch the plastic film to wrap automatically. Then,users can set the number of coating layers(2 to 4 layers).

How to prepare before use baling and wrapping machine?

First, connect the main power supply, and adjust all delayer and timers for a total of five. Then, adjust the air pressure to 6MPa. Place the film on the holder and fix it;

Next, turn the switch to the automatic gear and open the emergency stop button. Set the procedure to be automatic. Press the button to start the machine;

Finally,pass the rope. Firstly, pass the rope through the barrel. Then there is a compression port. After pulling the rope out, adjust the screw to tighten and pass through the guide hole. In the end, let the rope roll from the wire feeding tube and all in finished.

Details of straw silage baler wrapper machine

Silage baler and wrapper machine also can match with diesel engine as power.

Qiongdan machinery company is specialized in manufacturing animal feed processing machine, like grass cutter, sliage baler machine, etc. Our company is located in Zhengzhou City, Henan Province. The technology, trade and service is the core of global companies, and our company is committed to global customers with high standards of product manufacturing, and a full range of technical services and efficient solution.

Service before sale

24 hours online to answer questions that you want to know(Whatsapp, wechat, QQ, Skype, Trade Manager, etc), or you can send email to my email, I will give you a satisfying answer.

Service on sale

1.To provide customers with the new and high quality animal feed pellet machine.

2.Provide pictures that the customer desired about the animal feed pellet machine during production, in the warehouse and before transport.

3.Payment is determined by both parties.

4.Customers to choose the mode of transport.

After-sales services

We offer one year warranty for the whole machine except easy broken parts, Providing the spare parts with favorable price all the time 24 hours online service.

1.What is the MOQ of this product?Can I purchase one set as a sample?

The MOQ of this machine is 1 set , we support our customers to buy one set as a sample.

2.If I buy a large amount at one time, can you give me a discount?

Absolutely, we can give you a favorable price according to the quantity you order.

3.How can I use this machine?

This machine is quite easy to use, we will send you the manual and there will be professional staffs guide you to operate this machine.

4.How can I buy this machine?

We will draft the assurance order for you,and you can pay this order by your credit card, visa, mastercard, e-checking, T/T.

5.Which kind of shippment do you support?

Sea transportation, air transportation and international express.

6.When will you deliver the machine?

We will deliver the machine in 7-10 workdays after you pay the balance payment.

7.Can I become your agent?

As long as your company through the ability review by my company, you can become the sales agent of our company.

If you have any questions, please come to our company, and you will be assured that we can make a partner who worthy of your trusted.

Reviews

There are no reviews yet.