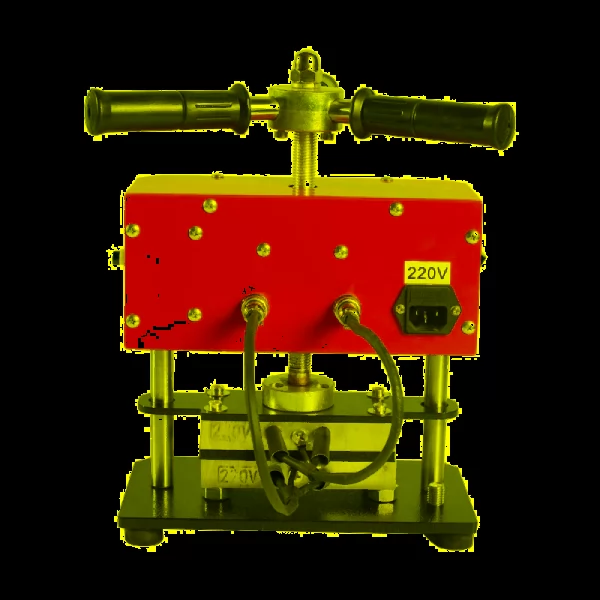

Automatic Plastic Sheet Butt Welding and Plate Rolling Machine SWT-PH3000

polyethylene containers butt fusion Welding Machine for Wastewater treatment systems, Caissons

THIS MACHINE IS OVERWEIGHT,WE CAN SHIP BY SEA OR BY AIR.

THE PRICE IS FOB CHINA,PLEASE TELL US YOUR DESTINATION PORT, THEN WE CAN CONFIRM THE SHIPPING COST.

SWT-PH series Sheet Butt Fusion Welding Machine

SWT-ZW series Bending Welding Machine

SWT-PZ series All in one bending butt fusion welding machine

SWT-YF series Engraving machine

SWT-XL series Cutting Saw

Welding Function:

Horizontal weld & round (rolling) weld. Rolling the circular minimum size is 500mm, the bigger circular unlimited.

| Size | SWT-PH2000 |

| The rated voltage | 380V,50/60Hz |

| Weldable sheet thickness | 3.0-30.0mm |

| Max.working length | 2000mm |

| Roll circle diameter minimum | 380mm |

| Air pressure(kg.f /cm2) | 4.0-8.0 |

| Energy source(m3/min) | 0.0032 |

| Rated current | 9A |

| Heating Power | 4kW |

| Power of Rolling Motor | 1.5kW |

Automatic plastic sheet hdpe plate butt fusion pp welder machine has three welding function:

1. rolling to cylinder

2.butt joint

3.corner joint

Wide applicability:

Our model is suitable for all types of thermo plastic sheet (PP, PE, HDPE, PVDF, PVC, PPN),

with material thickness ranges from 3 mm to 30 mm. Welding thickness can up to 50 or 60mm according to customers’ request.

Warranty:

Machine Quality Guarantee : 24 months.

If any parts broken or does not work under normal operating, we are free to provide.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPLICATION:

Manufacture of reservoirs, tanks and containers, manufacture of plastic apparatus, pipeline construction, ventilation systems, serial welding, water treatment systems, scrubbers, environmental technology, swimming pools, transport and logistics.

Reviews

There are no reviews yet.