Factory Direct Sales Auto-feeding CNC Wood Lathe TJ1530af with Turning and Fluting Process for Furniture Business

Jinan Tianjiao Machinery Manufacture Co., LTD Forcuing on CNC Machines for More than 11 Years

Specification:

1. Whole machine is welded with seamless steel structure, which is high temperature annealing

and vibrating stress relief, machine weight up to 1500kgs to make sure the lathe body

stabilized and never deformed.

2. Special used for wood turning and wooden cylinder engraving, for table legs,

stair railing (banisters), etc.

3.Adopting advanced handheld DSP system with USB port which is easy for operating even without a computer

4. Adopt Germany ball screw and Taiwan HIWIN helical square guide rail with high precision

and longevity.

5. Compatible with several CAD/CAM design software, e.g. type3, artcam, etc.

6. Rotating speed can be adjusted by inverter also you can see speed on control cabinet panel

7. One time tool setting to finish the whole work piece.

8.Turning,broaching and engraving can be done with one machine by high speed

Application:

Staircases,stairway balusters,stairway newel posts;dining table legs;end table Legs;sofa table legs;

bar stool legs;chair legs;chair arm posts;chair stretchers;bed rails, lamp posts,baseball bats and so on .

Technical Data:

|

Item Specification |

||

|

Max processing length |

1500mm(can custom 2000/2500/3000mm) |

|

|

Max turning diameter |

300mm |

|

|

Air pressure |

0.6-0.8Mpa |

|

|

Powersupply |

AC 380V 3 phase 50HZ/60HZ(can custom 220V) |

|

|

Max feed rate |

200cm/min |

|

|

min setting unit |

0.01cm |

|

|

Transimission type |

ballscrew for X,Z axis,gear for Y axis |

|

|

Guider |

Taiwan Hiwin orbit |

|

|

Main shaft rotating speed |

0-3000r/min |

|

|

Spindle power |

4kw |

|

|

Cutter material |

Super hard alloy |

|

|

Control System |

DSP control system |

|

|

Motor |

Servo motor |

|

|

Driver |

Yako driver |

|

|

Inverter |

Best inverter |

|

|

Drawing Software |

AutoCAD |

|

|

Hand controller recognise file |

*.dxf |

|

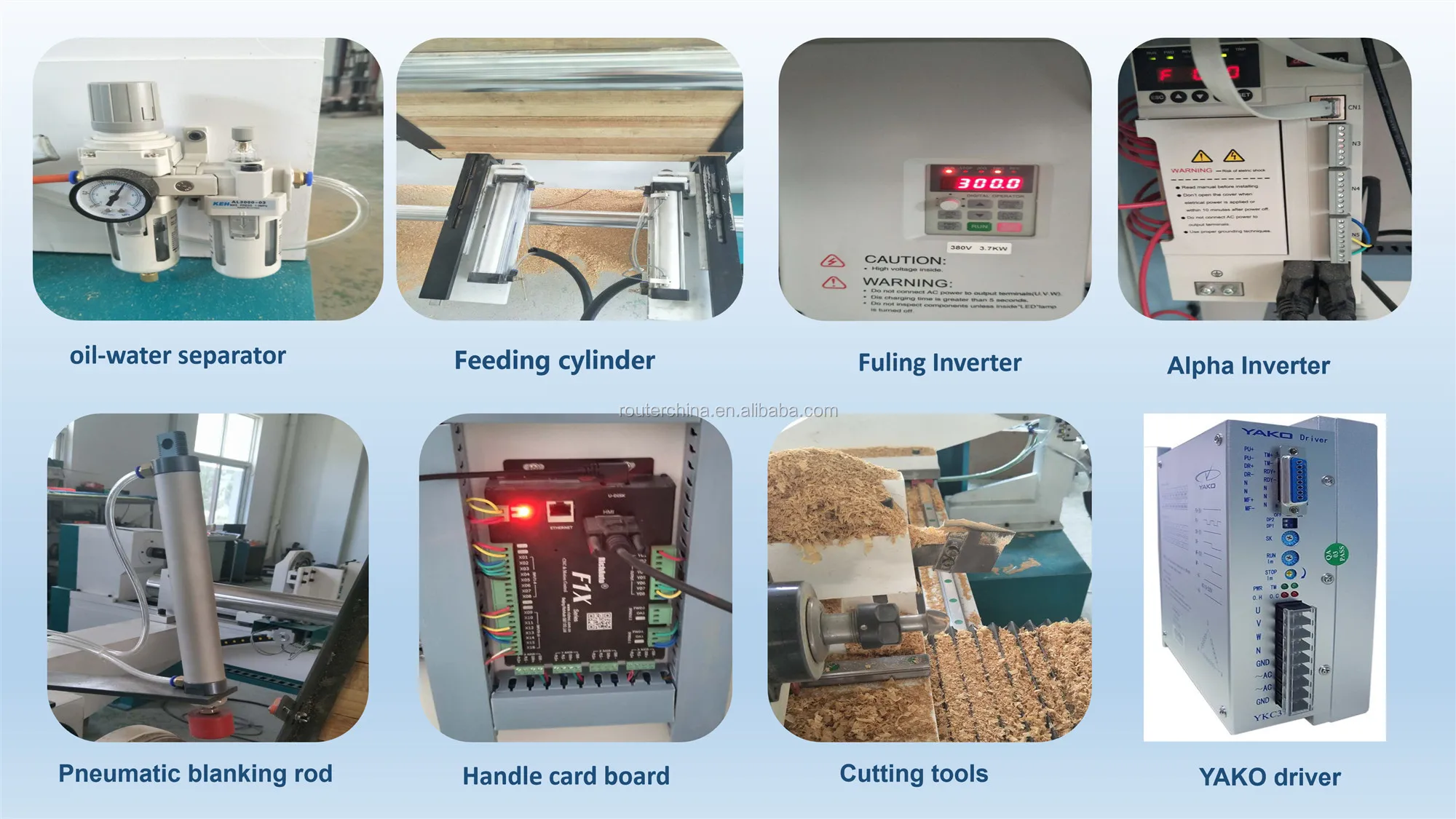

Machine Accessories:

Samples:

1. Outside package: Sandard export wooden cases and pylwood cases

2. Inner package: Stretch film

– One year machine warranty ,during the warranty period , if any parts broken,

we change a new part for you freely.

– All machines are debugged before shipment.

– We offer detailed machine manual, software manual, controller manual.

– Our factory make a vivid traing CD.

– 24 hours on line or phone or by email technical support.

– Longlife time freely provide technical support .

– One year , freely guarantee

– Free training course at our plant.

– Welcome to visit our factory, learn machine face to face.

Q1: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can

recommend the most suitable machine according to our experience.

Q2: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can

also help you by “Team viewer”online, with telephone or Skype explain.

Q3: Can you customize the machine for me?

Yes, we provide customized solution, but considering the cost, we will recommend the

standard configuration to you first.

Q4: What is the guarantee? In case the machine break down?

The machine has 1 year guarantee, fail parts will be replaced for free if the machine under

“ normal operation”.

Q5: How about the documents after shipment?

We will send all the documents by air after shipment. Including packing list, commercial

invoice, B/L, and other certificates required by clients.

Q6: Delivery time?

For standard machine, it would be 7-10 working days; for non-standard machine, it would be

20 – 30 working days.

Q7: How is the payment?

Normally we accept T/T or L/C, if you like other terms, tell us in advance.

Q8: Do you arrange the shipment for me?

For FOB or CIF price, we will arrange shipment for you, for EXW price, you should arrange

the shipment by yourself.

Q9: How is the packing?

Step1: water proof wrapping film with foam protection in each corner.

Step2: Solid seaworthy wood box package with steel belt.

Step3: Save space as much as possible for container loading.

Reviews

There are no reviews yet.