Specification Of CNC Wood Turning Lathe

1. Whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, machine weight up to 1500kgs to makr sure the lathe body stabilized and never deformed,

2. Special used for wood turning and wooden cylinder engraving, for table legs, stair railing (banisters), etc.

3. Adopting advanced handheld DSP system with USB port which is easy for operating even without a

computer.

4. Adopt Germany ball screw and Taiwan HIWIN helical square guide rail with high precision and longevity.

5. Compatible with several CAD/CAM design software, e.g. type3, artcam, etc.

6. Rotating speed can be adjusted by inverter also you can see speed on control cabinet panel.

7. One time tool setting to finish the whole work piece.

8.Turning,broaching and engraving can be done with one machine by high speed.

Application Of CNC Wood Turning Lathe

Technical Data Of CNC Wood Turning Lathe

|

Item

|

Specification

|

|

Max. Processing Length

|

1500mm(can custom 200/2500/3000mm)

|

|

Max. Turning Diameter

|

160/300mm

|

|

Power Supply

|

AC380V 3Phase 50HZ/60HZ(can custom 220V)

|

|

Max. Feed Rate

|

2000mm/min

|

|

Min. Setting Unit

|

0.01cm

|

|

Transimission Type

|

Ballscrew For X Z Axis, Gear For Y Axis

|

|

Guider

|

Taiwan HIWIN Orbit

|

|

Main Shaft Rotating Speed

|

0-3000r/min

|

|

Motor

|

Stepper Motor

|

|

Motor Power

|

4.0kw

|

|

Gutter Material

|

Super Hard Alloy

|

|

Control System

|

DSP Control System

|

|

Driver

|

YAKO 2811 Driver

|

|

Inverter

|

FULING 3.5kw

|

|

Drawing Software

|

AutoCAD

|

|

Interface

|

Internet Cable

|

|

Spindle Power

|

4.0kw Air Cooling

|

Standard Configuration Of CNC Wood Turning Lathe

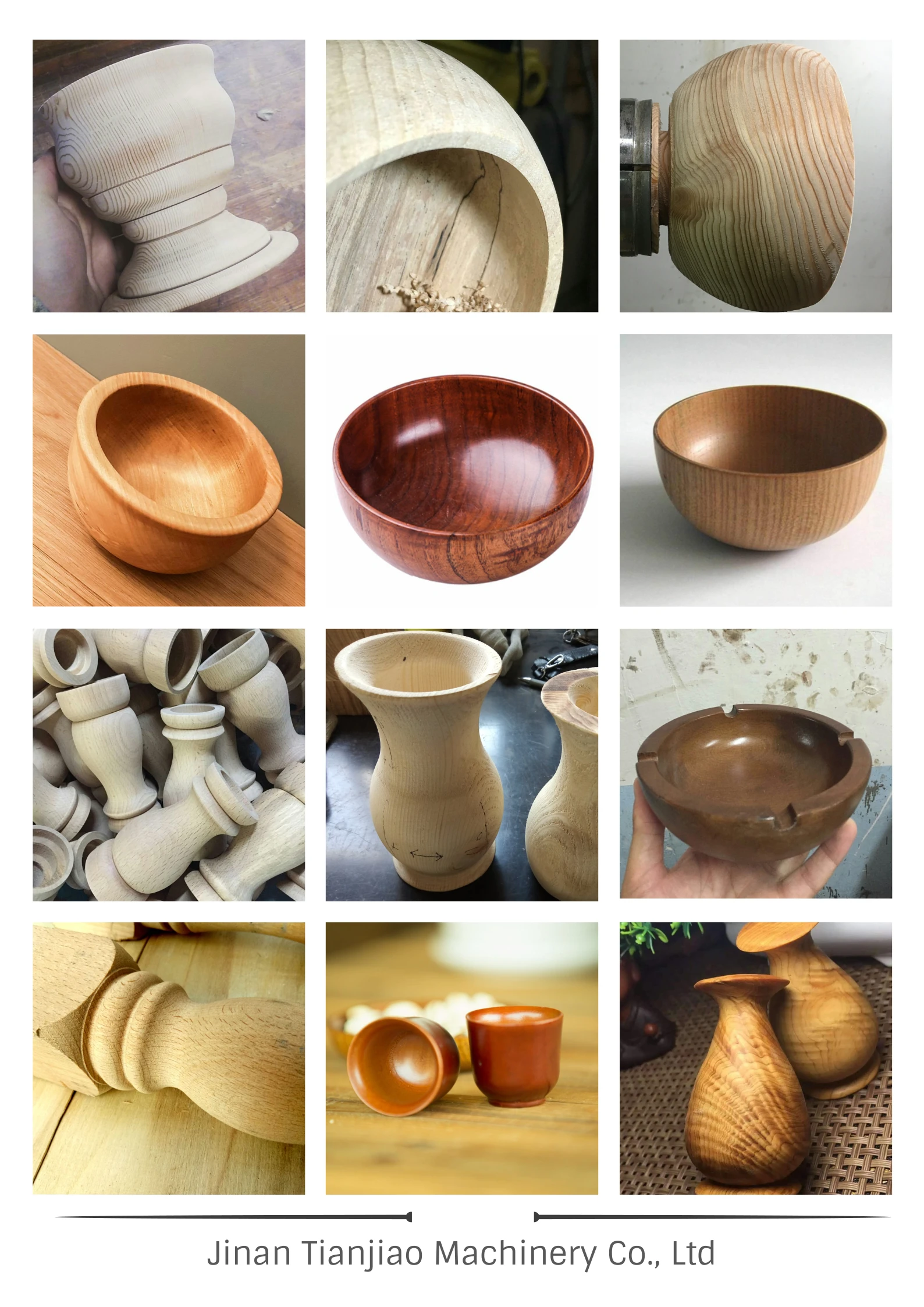

Samples Of CNC Wood Turning Lathe

Auto Tool Change Device With Four Knife For Turning, Drilling Wood

3.5KW Changsheng Air-cooling Spindle For Broaching And Carving Wood

When use the Chuck to fix the wood, the MAX. diameter of the wood will be 160mm.

If use thimble to fix the wood, the MAX. diameter of the wood will be 300mm.

Control Cabinet

Tianjiao Brand Control System

Heavy Steel frame

Cylinder

Taiwan PMI Square Rail And Slider

Inside Packing

Use professional Stretch Film to cover the whole lathe

Stretch film package with foam protection in each corner.

Outside Packing

Save space as much as possible for container loading.

Transport

We support shipping, air, land and express

You can choose the most suitable way of transport

If you have any special request for packing, we can do it

If you are interested in our any products, please do not hesitate to contact us.

For offer the exactly quotation timely. Please tell us more questions with RFQ as below:

(1). Where's the working area? Such as Country or end-user place.

(2). What kind of work do you want to do? Such as cutting column or engraving panel.

(3). What's the workpiece material you want to process? Such as the wood species and the stock thickness you want to process.

(4). What's the sample do you want to engrave or cut? Such as sample name or pictures.

We also welcome you to our factory for visiting,and the visiting lines as below:

Factory exact address:

Licheng District,Fujia Industrial Area, Yuhua 8th Rd.,Jinan City,Shandong Province,China.

1.By air to BEIJING International Airport, JINAN or QINGDAO Airport of Shandong,China.

2.By high-speed train to Qingdao or JINAN Railway station of Shandong Province,China.

Service

To provide clients with all aspects of after-sales service.

Our company promises:

One year free warranty for the whole machine , lifelong maintenance.

Customer response service time within 12 hours.

After the expiry of the warranty , we continue supply life-long maintenance services.

After the expiry of the warranty , still to provide a wide range of software and hardware support , enjoy free lifelong upgrades . And supply the parts at agent price

Warranty

(1). The engineers of the original factory are available to do all kinds of the original factory are available to do all kinds

of oversea machinery service. In some countries, we have oversea agents doing after-sale service in time and professionally.

(2). we also offer 24 hours heart to heart service on-line or mobile.

(3).Your technologists could attend the training in our factory and on-line which be free of chaege

(4).The warranty of CNC lathe is 12 months, small broken parts could be freely replaced at any time, spare parts are delivered with machine for customer convenience.

(5). We offer you best agent price and distributer price for our further cooperation .

(6). we can offer special custom-made according to your request.

Q1: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can

recommend the most suitable machine according to our experience.

Q2: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can

also help you by "Team viewer"online, with telephone or Skype explain.

Q3: Can you customize the machine for me?

Yes, we provide customized solution, but considering the cost, we will recommend the

standard configuration to you first.

Q4: What is the guarantee? In case the machine break down?

The machine has 1 year guarantee, fail parts will be replaced for free if the machine under

" normal operation".

Q5: How about the documents after shipment?

We will send all the documents by air after shipment. Including packing list, commercial

invoice, B/L, and other certificates required by clients.

Q6: Delivery time?

For standard machine, it would be 7-10 working days; for non-standard machine, it would be

20 – 30 working days.

Q7: How is the payment?

Normally we accept T/T or L/C, if you like other terms, tell us in advance.

Q8: Do you arrange the shipment for me?

For FOB or CIF price, we will arrange shipment for you, for EXW price, you should arrange

the shipment by yourself.

Q9: How is the packing?

Step1: water proof wrapping film with foam protection in each corner.

Step2: Solid seaworthy wood box package with steel belt.

Step3: Save space as much as possible for container loading.

● the foundation construction unit shall provide the quality certificate of the equipment foundation (such as ratio, maintenance, strength).

● if there is doubt about the strength of the equipment foundation, the strength of the foundation can be re-measured by springback instrument or steel ball impact method.

● check the appearance of the foundation

● check the position and geometry of the foundation

Preloading test of heavy equipment base is to prevent the heavy equipment due to the uneven subsidence of the foundation after installation equipment installation is unqualified preloaded pressure not less than equipment running at full capacity (the sum of the force on the basis of equipment), the heavy equipment can be installed level requirement is not high, only when the equipment test run on the basis of settlement observation.

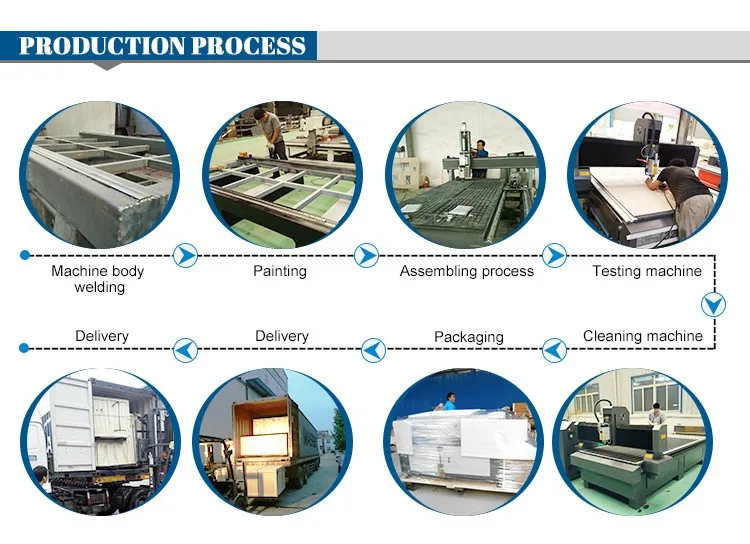

2.Painting

3.Assembling process

4.Testing machine

5.Cleaning machine

6.packing

7.delivery

8.transport

Reviews

There are no reviews yet.