Product Description

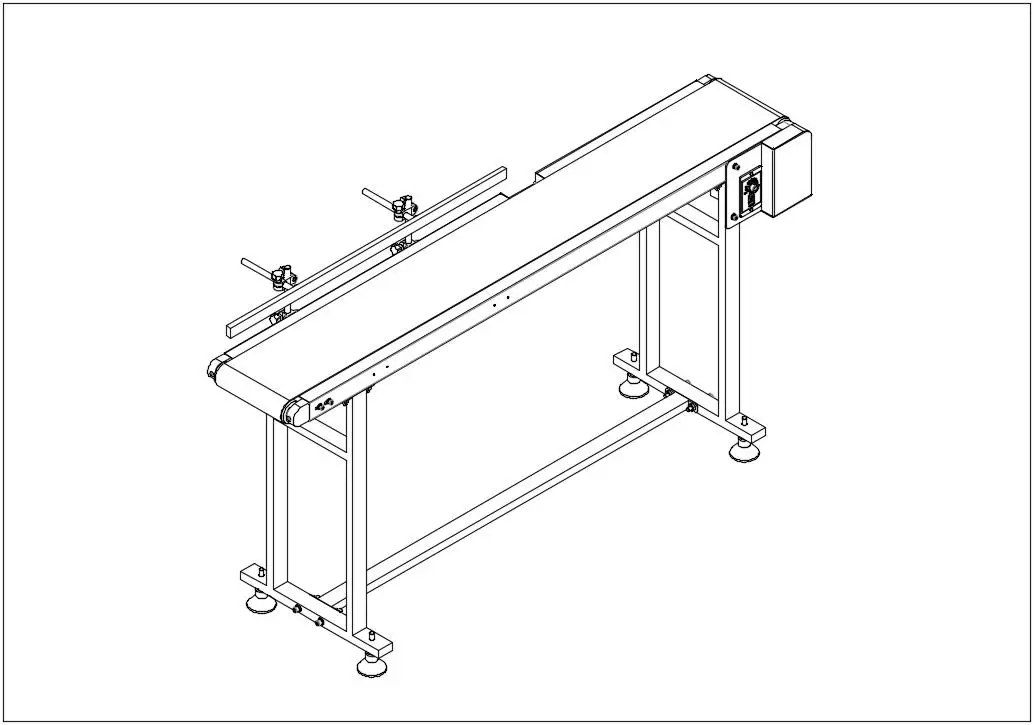

Coding Conveyor

Scope of application:

Glass bottles, plastic bottles, metal cans, plastic bags, cartons, carton boxes, labels etc.

Application:

Used for conveying glass bottles, plastic bottles, metal cans, carton, carton boxes, labels etc, so as to facilitate the coding machine or laser machine to spray printing or spray etch the date of production, batch number, anti-fake mark, pattern, etc.

Industry application:

Such industry as food, beverage, pharmacy, electronics,tobacco,chemical engineering, automobile components and parts etc.

Glass bottles, plastic bottles, metal cans, plastic bags, cartons, carton boxes, labels etc.

Application:

Used for conveying glass bottles, plastic bottles, metal cans, carton, carton boxes, labels etc, so as to facilitate the coding machine or laser machine to spray printing or spray etch the date of production, batch number, anti-fake mark, pattern, etc.

Industry application:

Such industry as food, beverage, pharmacy, electronics,tobacco,chemical engineering, automobile components and parts etc.

Instructions:

The first operation sequence is basically performed in the following order

1. First of all, according to the picture shows the machine installed.

2. Plug the power supply into a single-phase power supply (a good ground connection is required).

3. Open the switch button, knob speed twist handle.

4. If you encounter belt deviation, you can adjust the screw inside the rear aluminum block, Each adjustment is just fine adjustment, the belt will run slowly after a few weeks recovery, if transferred too much, the belt will shift to the other party.

The first operation sequence is basically performed in the following order

1. First of all, according to the picture shows the machine installed.

2. Plug the power supply into a single-phase power supply (a good ground connection is required).

3. Open the switch button, knob speed twist handle.

4. If you encounter belt deviation, you can adjust the screw inside the rear aluminum block, Each adjustment is just fine adjustment, the belt will run slowly after a few weeks recovery, if transferred too much, the belt will shift to the other party.

Kindly Notes:

* Make sure that the power switch is in the "off" state before plugging in the machine, and then follow the manual procedure.

* The machine does not work for a long time to use a dry cloth Sassafras net, do not use a corrosive detergent.

* Do not spill liquid into the inside of the machine box to avoid corrosion or short-circuit the internal electrical components.

* Check the appearance of equipment should be no deformation, damage and corrosion, the shaft should be flexible rotation, no jam phenomenon.

* This machine is single-phase AC 220V power supply wiring for the 3-line flat plug, should be connected to the ground of the 3 plug socket.

* Be careful not to receive 380V power supply, otherwise it will burn the machine.

* Make sure that the power switch is in the "off" state before plugging in the machine, and then follow the manual procedure.

* The machine does not work for a long time to use a dry cloth Sassafras net, do not use a corrosive detergent.

* Do not spill liquid into the inside of the machine box to avoid corrosion or short-circuit the internal electrical components.

* Check the appearance of equipment should be no deformation, damage and corrosion, the shaft should be flexible rotation, no jam phenomenon.

* This machine is single-phase AC 220V power supply wiring for the 3-line flat plug, should be connected to the ground of the 3 plug socket.

* Be careful not to receive 380V power supply, otherwise it will burn the machine.

Product Display

Automatic friction feeder conveyor for inkjet printing advantage:

1. Automatic speed and steady speed circuit of the electronic governor, have higher stability.

2. This is mainly used for conveying glass bottles, plastic bottles, bottle caps, metal, plastic bags, paper boxes, cartons, labels etc.

3. Easy to spurt the code machine, laser machine on production line, printing code, is each brand spurt the code machine, laser machine for spraying, spraying carving production date, batch number anti-fake mark, design must form a complete set of equipment.

4. Application industry: Food, beverage, pharmaceutical, electronic parts, tobacco, chemical industry, cosmetics, auto parts etc.

1. Automatic speed and steady speed circuit of the electronic governor, have higher stability.

2. This is mainly used for conveying glass bottles, plastic bottles, bottle caps, metal, plastic bags, paper boxes, cartons, labels etc.

3. Easy to spurt the code machine, laser machine on production line, printing code, is each brand spurt the code machine, laser machine for spraying, spraying carving production date, batch number anti-fake mark, design must form a complete set of equipment.

4. Application industry: Food, beverage, pharmaceutical, electronic parts, tobacco, chemical industry, cosmetics, auto parts etc.

Product Paramenters

|

Device name

|

Belt conveyor

|

|

Model

|

LBC200

|

|

Speed

|

9-30 meters/min

|

|

Voltage

|

220V

|

|

Motor

|

Reduction motor

|

|

6Power

|

60w

|

|

Speed regulation mode

|

Electronic stepless speed regulation

|

|

Positioning mode

|

Double-side adjustable baffle

|

|

Width of belt

|

190mm

|

|

Dimension

|

1500*250*750mm

|

|

Remarks

|

Standard type

|

|

MAX Loading weight

|

10KGS

|

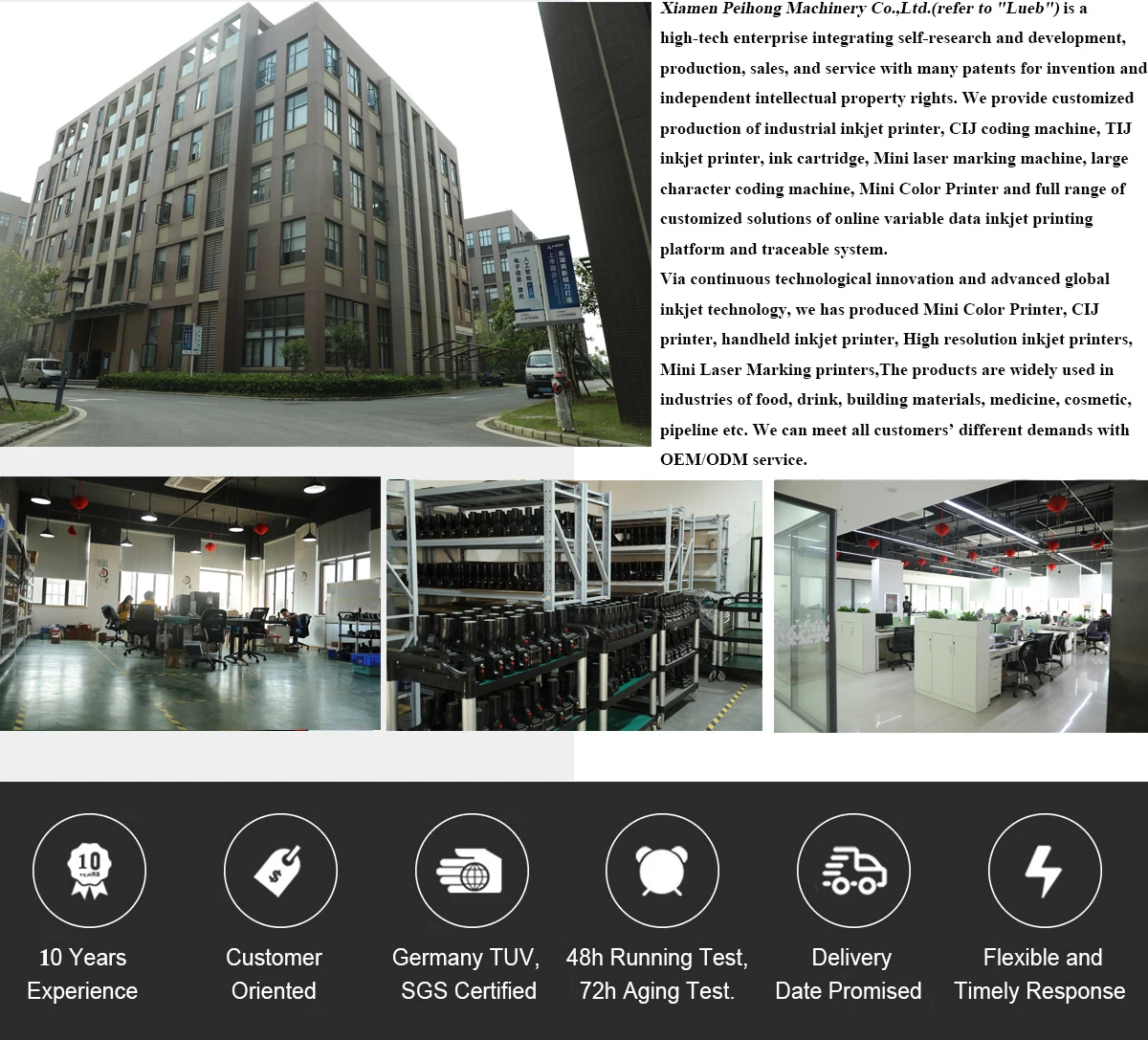

Company Profile

User Manual

The motor is factory-tested with the maximum speed, if it doesn’t run smoothly when reducing speed, could adjust the motor as follow:

1. Connect AC cable.

2. Transfer direction of conveyor,

3. Forward: connect COM and CCW,

4. Reverse: connect COM and CW

Ground: FG

2、Adjust

First, rotate speed control device clockwise to the end (fastest), adjust slightly clockwise (+direction) with a screwdriver. Motor is speeding up, and adjust the motor speed to the fastest stage which is without hum and the motor will not vibrate. Now the voltage across the motor speed control coil is AC 17-24V (various brands of motors will be different), otherwise it will rotate a little counterclockwise (-direction).

3. Note:

The pointer of speed control device cannot be adjusted to below the indicator light, otherwise it will cause unstable machine operation and motor damage.

1. Connect AC cable.

2. Transfer direction of conveyor,

3. Forward: connect COM and CCW,

4. Reverse: connect COM and CW

Ground: FG

2、Adjust

First, rotate speed control device clockwise to the end (fastest), adjust slightly clockwise (+direction) with a screwdriver. Motor is speeding up, and adjust the motor speed to the fastest stage which is without hum and the motor will not vibrate. Now the voltage across the motor speed control coil is AC 17-24V (various brands of motors will be different), otherwise it will rotate a little counterclockwise (-direction).

3. Note:

The pointer of speed control device cannot be adjusted to below the indicator light, otherwise it will cause unstable machine operation and motor damage.

Recommend Products

FAQ

* Q: Could you supply the customized service?

* A: Yes, we supply customize service to provide the special model, if it necessary please consult online customer service to get more details.

* Q: Could you provide accessories of the other side of the baffle?

* A: Yes, we can provide the same size of baffle to you.

* Q: How to package the conveyor belt?

* A: We use hard cardboard package, which fill with plastic foam to avoid the damage in transit.

* Q: Could your conveyor belt transport food directly?

* A: The standard belt has made by PVC material, also we supply the food grade PE material conveyor, please send us the size for customize.

* Q: How much bearing weight of your conveyor?

* A: The Bearing weight is 10kg at most in standard. More details please consult online customer service.

* A: Yes, we supply customize service to provide the special model, if it necessary please consult online customer service to get more details.

* Q: Could you provide accessories of the other side of the baffle?

* A: Yes, we can provide the same size of baffle to you.

* Q: How to package the conveyor belt?

* A: We use hard cardboard package, which fill with plastic foam to avoid the damage in transit.

* Q: Could your conveyor belt transport food directly?

* A: The standard belt has made by PVC material, also we supply the food grade PE material conveyor, please send us the size for customize.

* Q: How much bearing weight of your conveyor?

* A: The Bearing weight is 10kg at most in standard. More details please consult online customer service.

Reviews

There are no reviews yet.