Product Description

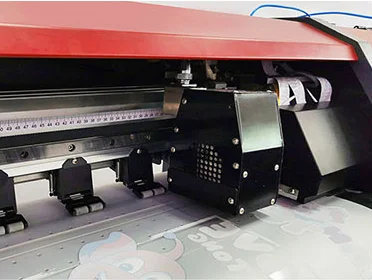

1.DTF printer : Mould integration platform , 1 key craved printing , no need cutting , white & color ink outputs in the same time , No need craved , high efficiency and fast.

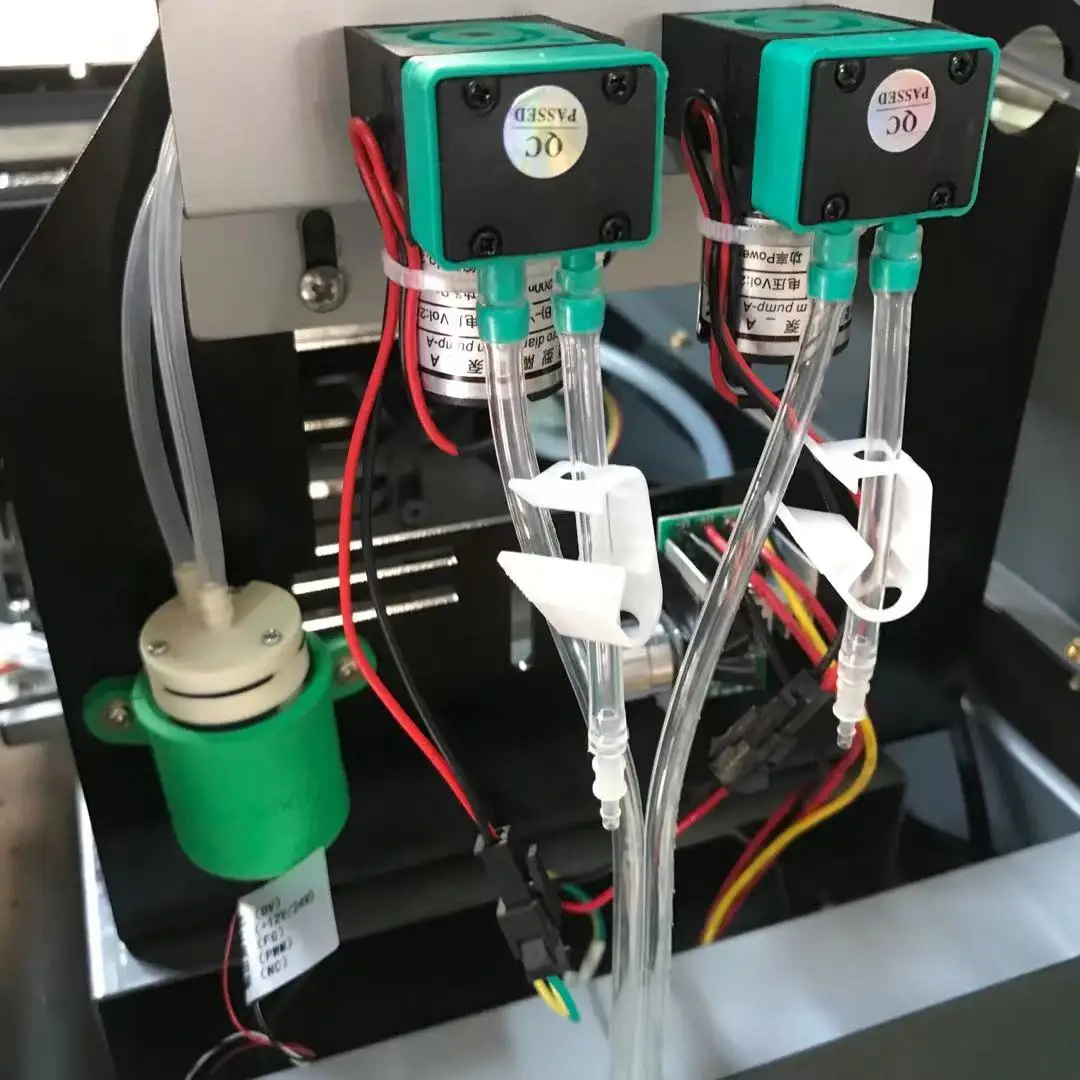

2.White ink stirring circle system : White ink stirring circle system , anti-sediment for white ink which will cause print head blocked , make sure the printing smoothness.

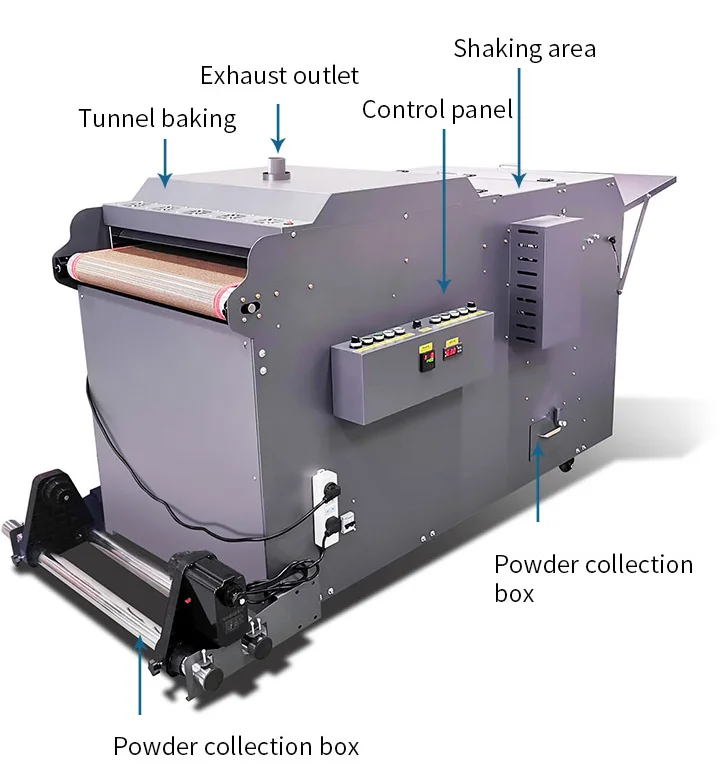

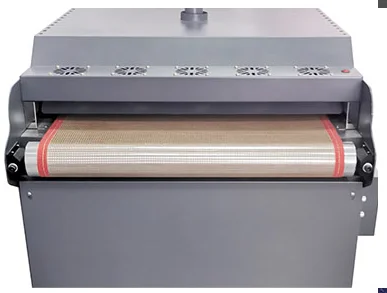

3.Tunnel baking : Tunnel baking system , make sure the hot melt powder heating balancely , can strengthen the washing fastness , print high-quality pyrograph.

4.Auto powder shaking machine : Intelligent powder shaking machine , splashing powder auto , powder shaking ,heating , belt heating , powder shake balancely , the washing fastness can up to grade 4.

Specification

|

item

|

value

|

|

Type

|

Inkjet A1 DTF Printer

|

|

speed

|

8 Pass:6sqm/h 6 Pass:9sqm/h

|

|

Color control

|

ICC color profile with adjust function

|

|

Place of Origin

|

China

|

|

Usage

|

Paper Printer, Cloths Printer

|

|

Voltage

|

Machine 50/60Hz, 110V/220V

|

|

Certification

|

CE, ISO

|

|

Environment

|

Temperature: 15-30°C, Humidity: 50-70%

|

|

service system

|

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

|

|

Print Dimension

|

600mm

|

|

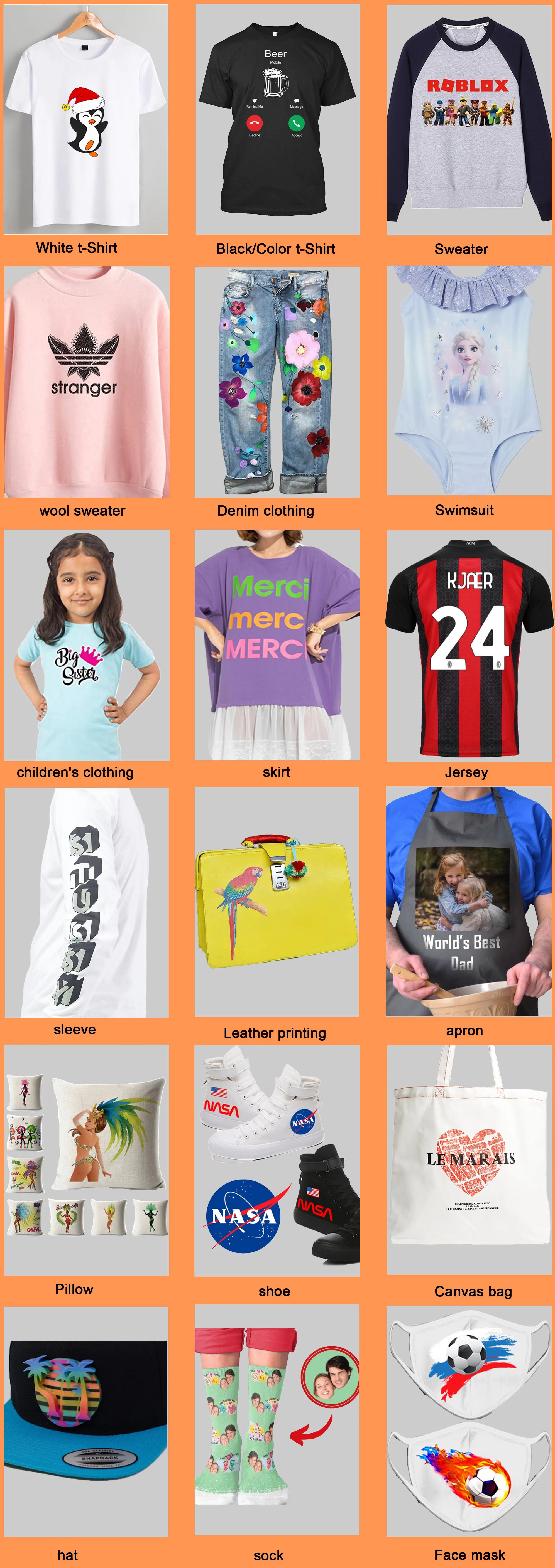

Application

|

Nylon, chemical fiber, cotton, leather, swimsuit,diving suit, PVC, EVA,etc.

|

|

Powder Treating Control

|

The direction and amount of powder scattering and shaking is adjustable

|

|

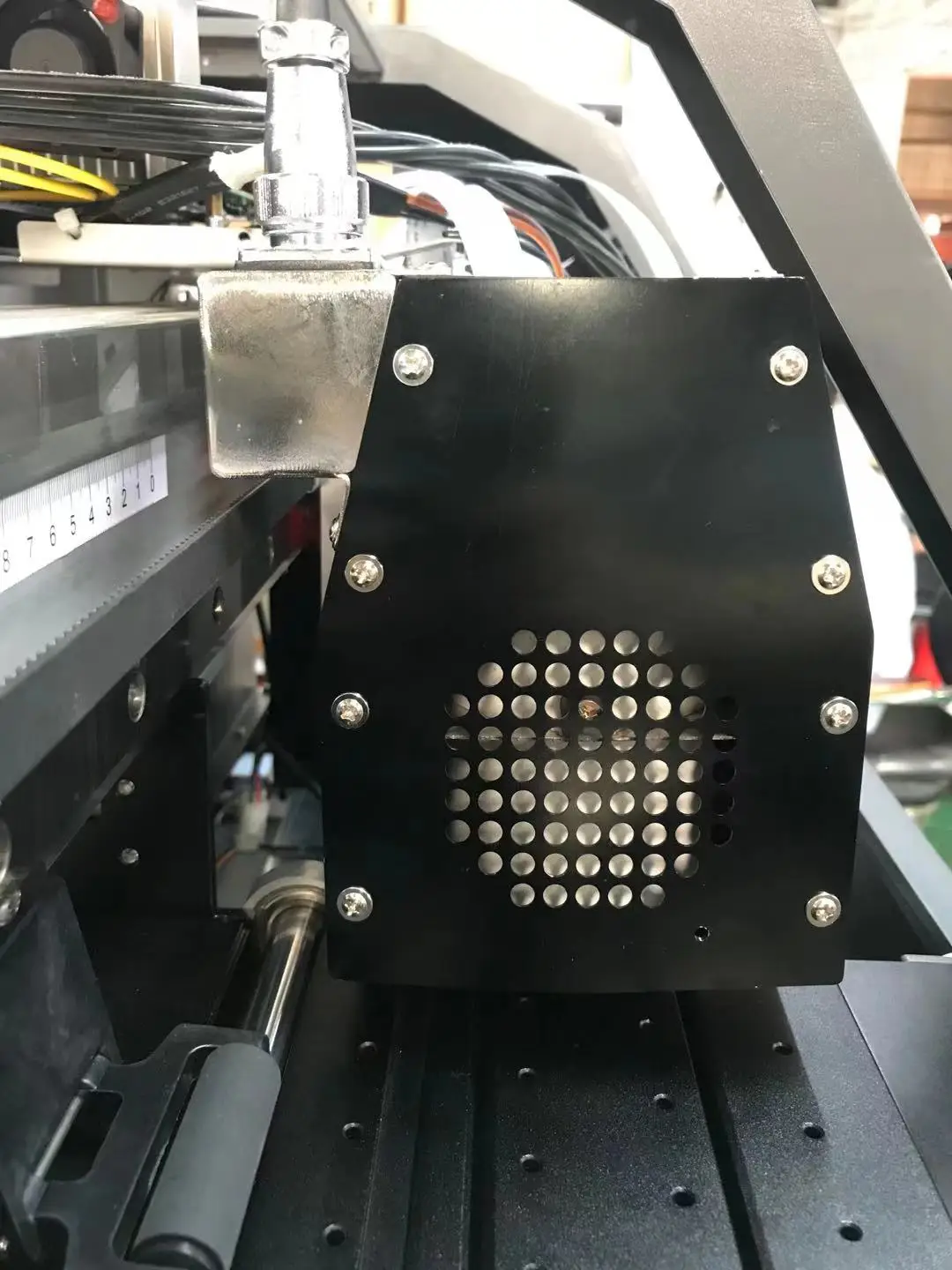

Printhead

|

With Epson i3200/4720 Heads (2 pcs)

|

|

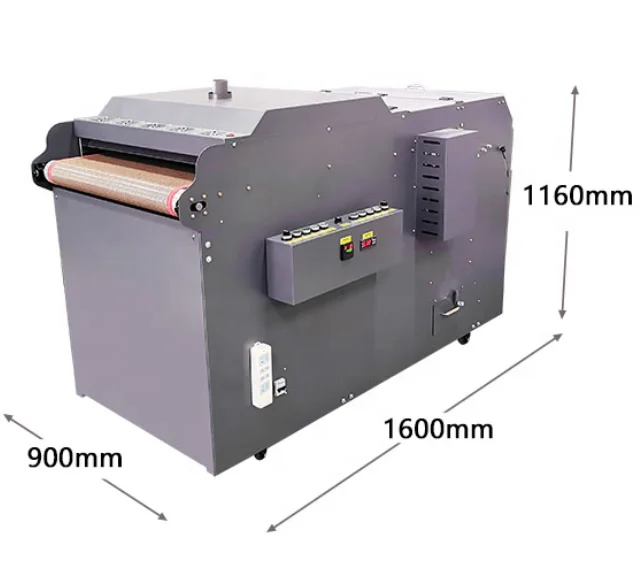

Powder Machine Diemension

|

1600*900*1160mm

|

|

Printer Dimension

|

1600*960*1300mm

|

Details Images

60cm mini roll to roll printer.

1.Bringht colors.

2.Simultaneous color and white printing.

3.Hollow pattern without cutting.

2.Simultaneous color and white printing.

3.Hollow pattern without cutting.

4.Easy to find space for it in the office,and extend the business to new area.

shake power

1.accurate alignment of printed patterns.

2.Sprinkle hor melt adhesve powder evenly.

3.Shake powder quickly.

Drying system

1.Cold wind drying system

The pattern dries quickly.

2.Protect materials and bright colors.

The pattern dries quickly.

2.Protect materials and bright colors.

3.Suction can play a good role during drying to ensure that the finished product will not wrinkle.

Automatic winding

1.Automatic winding.

2.Assemble synchronous winding device.

3.Automatic winding after drying.

2.Assemble synchronous winding device.

3.Automatic winding after drying.

Heat transfer process

1.The pattern is clear and delicate.

2.Can be pulled without deformation.

3.Washable and not fade.

2.Can be pulled without deformation.

3.Washable and not fade.

Application

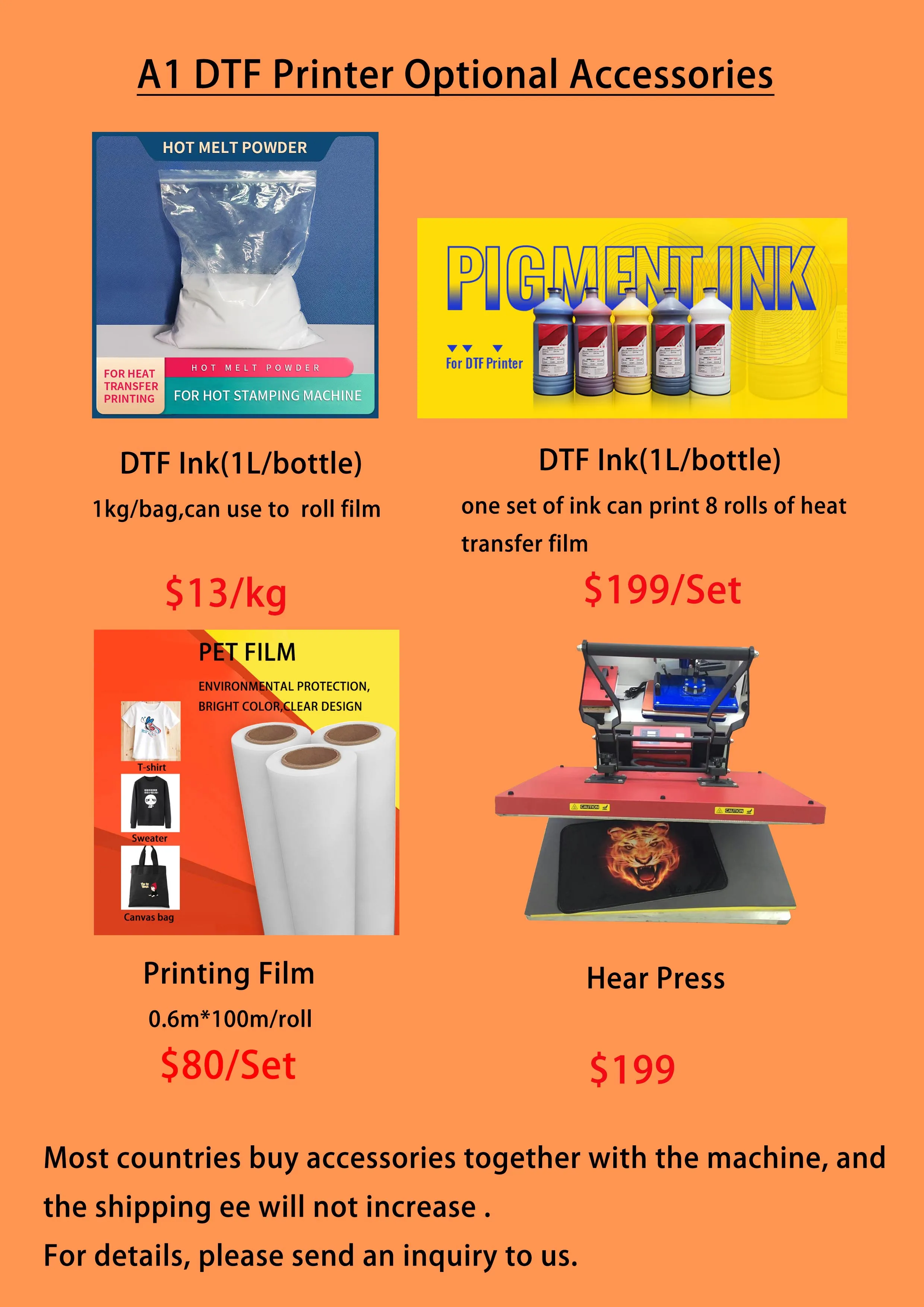

Recommend Products

Our Advantages

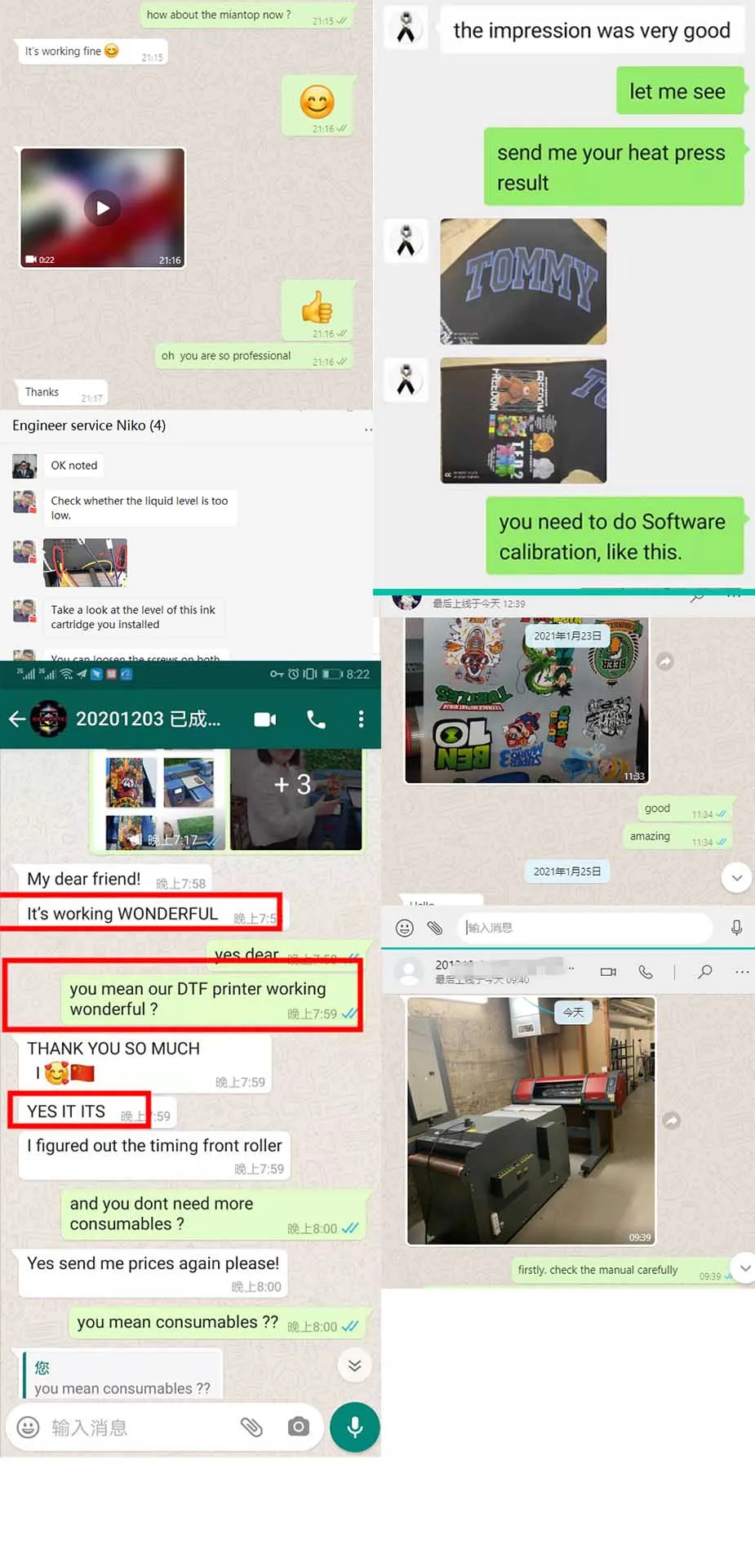

client feedback

Buyers’ praise

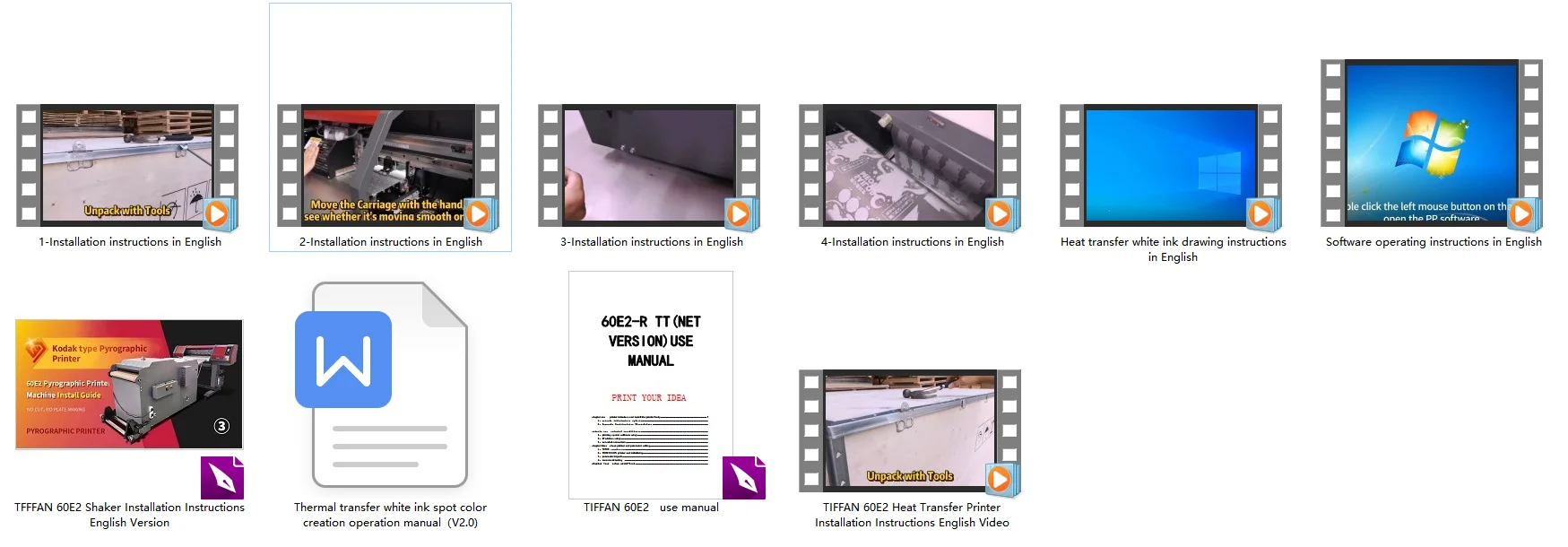

A1 DTF printer installation file and operation video

1.One year warranty, life-long after-sales service.

2.Technologist instant online support service.

3.One to one professional technical free training.

4.For printer ink, the more you order, the cheaper the price !

5.Welcome to visit our Company or Factory at any time.

2.Technologist instant online support service.

3.One to one professional technical free training.

4.For printer ink, the more you order, the cheaper the price !

5.Welcome to visit our Company or Factory at any time.

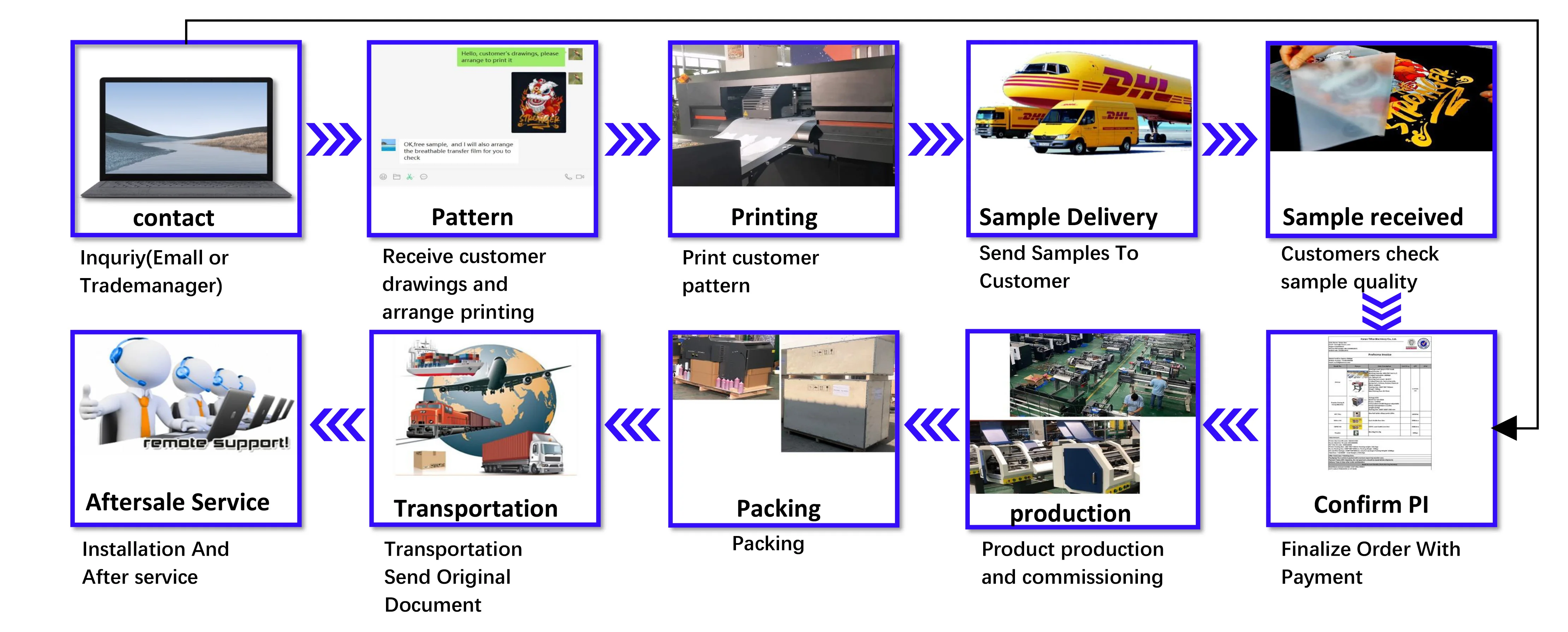

Packing & Delivery

|

Packaging attributes

|

(mm)Machine size(L×W×H)

|

(mm)Package dimensions(L×W×H)

|

net weight(kg)

|

total weight(kg)

|

|

Printer

|

1600*960*1300

|

1860*960*760

|

150

|

200

|

|

Shake powder machine

|

1600*900*1160

|

1800*1000*1400

|

150

|

200

|

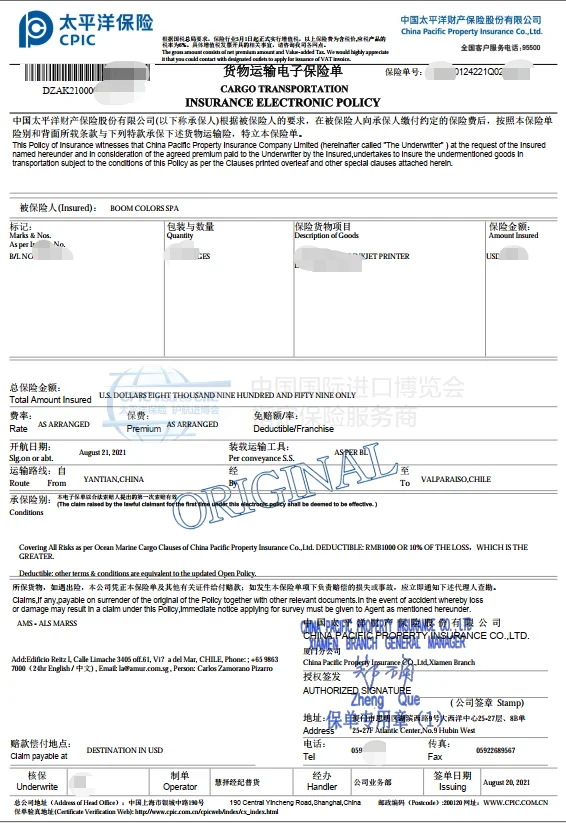

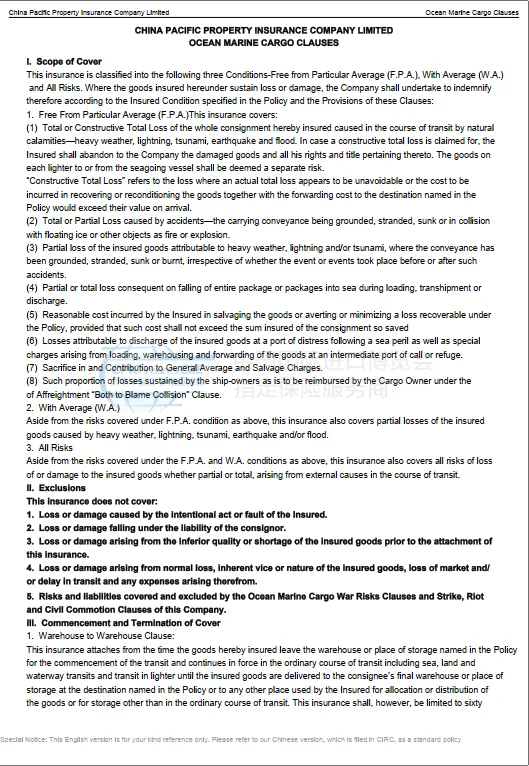

Purchase logistics insurance for buyers to reduce logistics risks

FAQ

Reviews

There are no reviews yet.