|

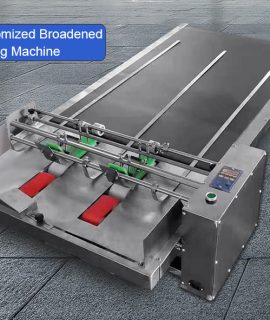

model |

BG-531R |

|

Drive mode |

Double rail timing belt |

|

Maximum speed |

X,Yaxis500mm/sec,Zaxis300mm/sec |

|

Power Source |

Stepper Motor |

|

Precision |

±0.05mm |

|

Max Load |

Synchronous pulley:X/Y/Z 5kg/5kg/3kg |

|

Motor power |

350W |

|

Control System |

Three-axis control system |

|

File storage |

A single processing file occupies |

|

Heating power |

150W |

|

Support documentation |

CAD, CorelDRAW |

|

Temperature range |

50-500 degrees |

|

Tin feeder |

Standard tin breaker |

|

Cleaning box |

Air blowing cleaning box |

|

Size |

L640.5*W585*H801mm |

|

Weight |

55kg |

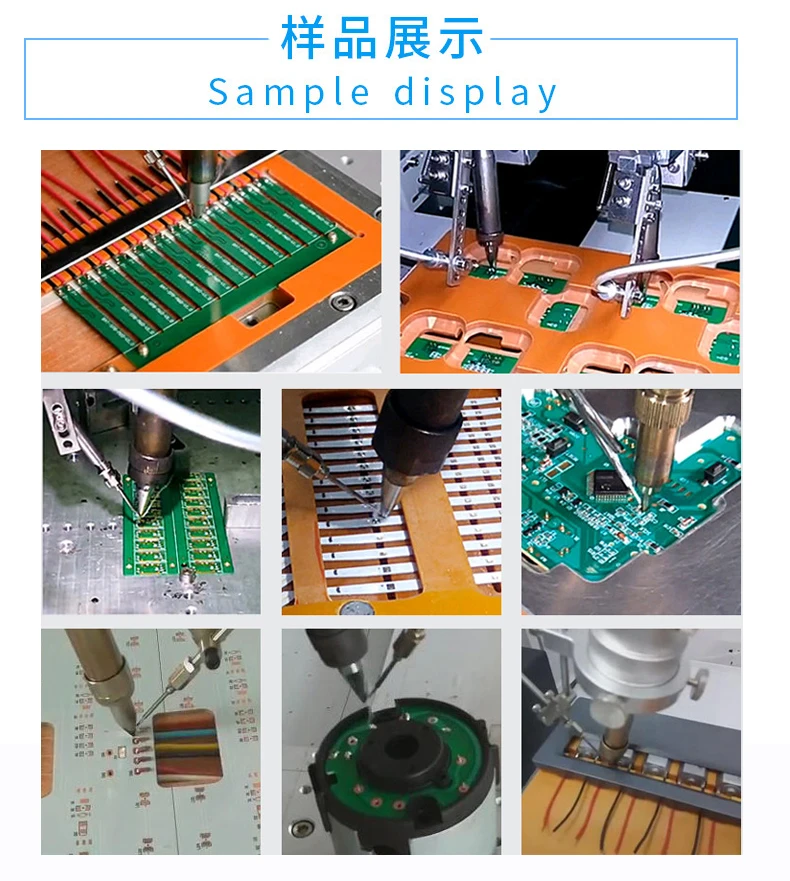

Aplication

1. Semiconductor products: LSI, IC, hybrid IC, CSP, BGA, etc.

2. Optical products: cameras, cameras, etc.

3. Electronic products: mechanical parts, printed motherboards, small switches, capacitors, variable resistors, crystal oscillators, LCDs, magnetic heads, relays, connectors, engines, transformers, etc.

4. General performance appliances: DVD, audio equipment, car navigation system, TV game console, TV, radio, washing machine, vacuum cleaner, etc.

5. Precision machinery / electrical products: VTR, video camera, electronic clock, personal computer, PDA, printer, copier, calculator, LCD TV, medical device

6. General consumer products: typewriters, toys, musical instruments, CDs, batteries, etc.

Feature

1. Flexible and diverse soldering methods, with functions such as spot welding and drag welding (pulling welding).

2. The device can store 99 operating programs. The same machine can perform solder processing on 99 different products.

3. Solder jitter function, turning on this function during welding can make welding faster, especially effective for large solder joints.

4. The solder joint trajectory is visible, which is convenient for the operator to understand the soldering progress, and it is convenient for the engineer to debug.

5. The mechanical arms of the equipment are all aluminum die-casting, without deformation, rust, and stable operation.

6. Equipment writing work program can be copied point-to-point, block-to-block, shortening the programming time, and easy to learn.

7, the equipment has an automatic cleaning function, to a certain extent stabilized the quality of solder processing and extended the life of the iron nozzle.

8. The multi-axis linkage manipulators are all driven by precision stepping motors and advanced motion control algorithms to effectively improve the accuracy of motion positioning and repeatability.

|

Packaging

|

||

|

Size

|

520mm(L) * 585mm(W) * 690mm(H)

|

|

|

Weight

|

90KG

|

|

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is

too tigher,we will use pe film for packing or pack it according to customers special request. |

|

1. Talk with our sales man and will get your fullrequirements; our engineer will design and creat the solution with engineering drawing;

2. after confirmed, we will start to prepare all stuff of the machine;

3.Assembly by another department will be the third step;

4. Debug and test will be a very important step ,make sure the machine working well before ship;

5. For sea transportation, the machine will be vacuum packed and waterproof to make sure arrives safe in long distance ship.

Customers’ satisfy is the most important for us. From our engineers to the assembly workers, we are clearly that only the best product and service brings long run relationship.You will have no worries to work with a professional manufature who have 10 years of experience of customization service.

Reviews

There are no reviews yet.