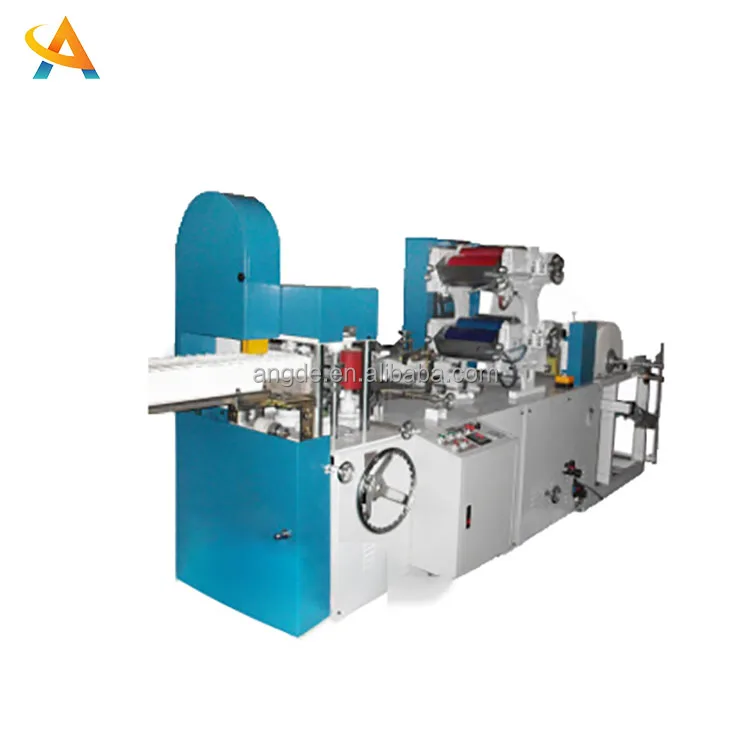

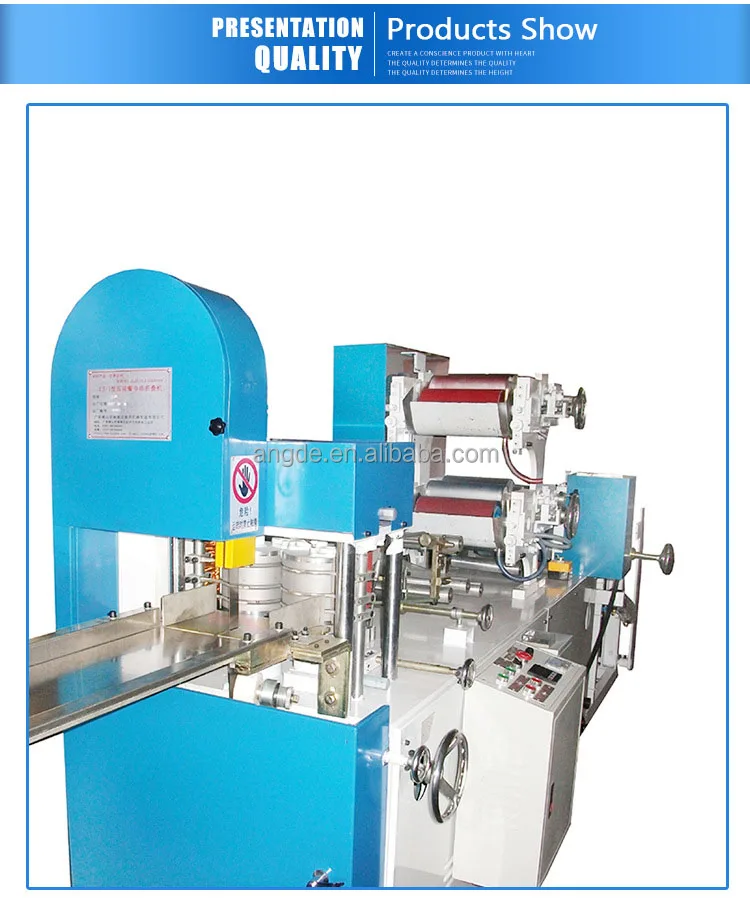

Product Description

1.The production process is : unreeling -→ embossing and gluing lamination-→perforating-→furl-→slitting

2. The combined pumping facial tissue machine can choose any combination of two rows, three rows, four rows, etc. Latest model automatic sealing packaging machine. 3. The pumping facial tissue machine is to cut the raw paper into a chain-like rectangle by vacuum adsorption, spiral knife roll shearing and interlocking folding. Shaped facial tissues have the advantages of high efficiency, neat folding and easy operation. 4. The packaging machine adopts PLC programmable controller, and high-sensitivity photoelectric detection sensor feeding, sewing temperature adopts Independent PID control, flexible and simple operation, higher production efficiency. 5. The combination of the two equipment can produce various specifications of pumping facial tissues, with high output, less waste, and convenient operation. It is a commonly used combination in the removable facial tissue industry.

Specification

|

Production speed

|

140-200m /min

|

|

Power of equipment

|

5.5kw (380V 50Hz)

|

|

Overall size(mm)

|

6200X2750X1800 (LxWxH)

|

|

Weight

|

About 3.2T

|

|

Width of raw paper

|

1200MM

|

|

Diameter of raw paper

|

700mm-1200mm

|

|

Thickness of raw paper

|

14g/m2-20g/ m2 or 38g/m2

|

Reviews

There are no reviews yet.