Product description

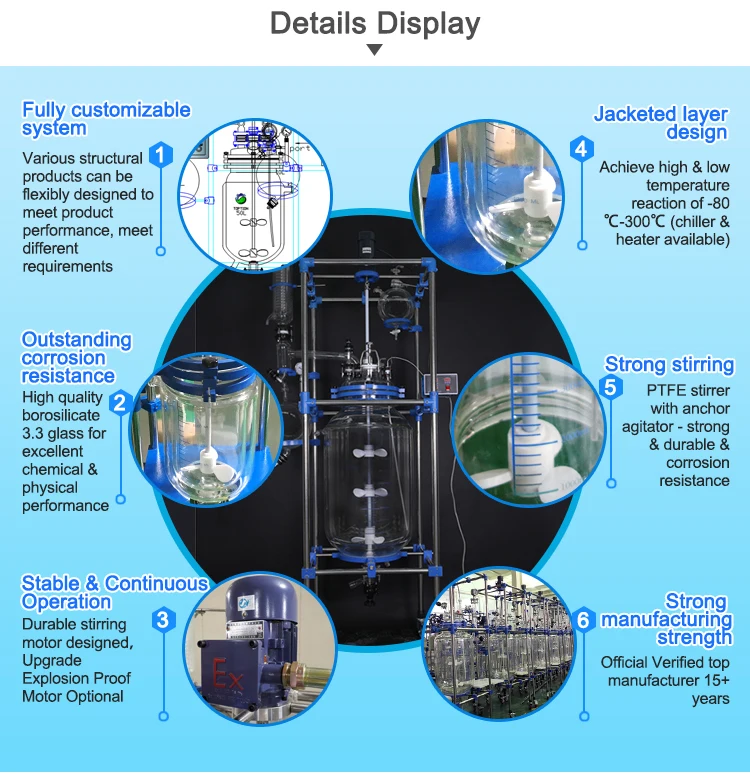

Glass chemical reactor is widely used in petroleum, chemical industry, rubber, pesticides, dyes, pharmaceutical and food, for the purpose to complete the sulfuration, nitration, hydrogenation, alkylation, polymerization, condensation and other process.For research, glass reaction vessel could do new materials synthesis, mixing homogeneous reaction, extraction and purification, distillation and samples purification.

|

product name

|

glass reactor

|

|

Model

|

TOPT-1L–TOPT-200L

|

|

Glass Material

|

Borosilicate Glass 3.3

|

|

Reaction bottle capacity

|

1L–200L

|

|

Jacketed Capacity

|

As designed/3L-40L

|

|

Reaction bottle cover flange

|

150–340/440 PP flange

|

|

Inner diameter of reactor body

|

113–550

|

|

Stirring power

|

40W–400W

|

|

Voltage(V/Hz)

|

110V 50Hz, 220V 50-60Hz, 110V/220V/380V, 50/60Hz

|

|

Temp. range

|

-120℃~300℃,digital display / LCD display on the controller

|

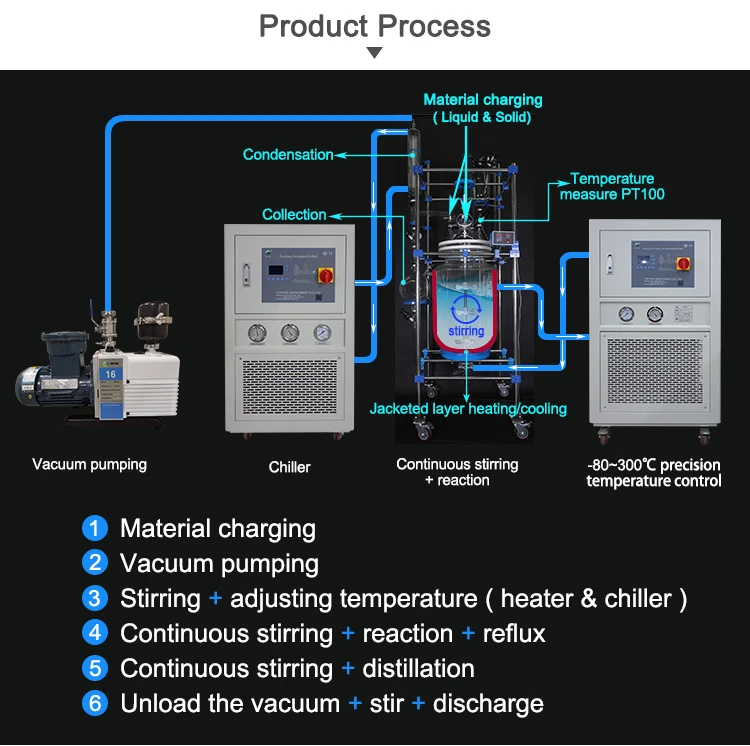

Production process

1. Use PTFE composite seal, it can maintain high vacuum degree.

2. Use efficient condenser to ensure high recovery rate.

3. The complete set of glass use GG17 high borosilicate glass with good chemical and physical properties.

4. The glass inter layer interface is added with hot oil, through the loop, it can do reaction under the condition of high temperature; the glass inter layer interface added with cooling fluid can carry on reaction under the condition of low-temperature.

5. It can be added with tap water to quickly take away reaction heat.

6. Discharged material has flanged opening and PTFE valve, without dead angle inside the container, it can be demounted to facilitate the discharge of solid materials.

7. Digital mixing motor, frequency conversion control, matched with a torque increasing of reducer.

8. Reasonable structure and selected materials. The mechanical components use stainless steel and aluminum-alloy pieces, the glass pieces use high borosilicate glass with high temperature resistance and good chemical properties. Electrical components parts: the main components use original imported devices.

2. Use efficient condenser to ensure high recovery rate.

3. The complete set of glass use GG17 high borosilicate glass with good chemical and physical properties.

4. The glass inter layer interface is added with hot oil, through the loop, it can do reaction under the condition of high temperature; the glass inter layer interface added with cooling fluid can carry on reaction under the condition of low-temperature.

5. It can be added with tap water to quickly take away reaction heat.

6. Discharged material has flanged opening and PTFE valve, without dead angle inside the container, it can be demounted to facilitate the discharge of solid materials.

7. Digital mixing motor, frequency conversion control, matched with a torque increasing of reducer.

8. Reasonable structure and selected materials. The mechanical components use stainless steel and aluminum-alloy pieces, the glass pieces use high borosilicate glass with high temperature resistance and good chemical properties. Electrical components parts: the main components use original imported devices.

Application

Packing And Shipping

Feedback

Certificate

Exhibition

Our Factory

Reviews

There are no reviews yet.