Advantage:

Plastic forming machine for vacuum packing switches to new energy-saving heat tiles which can save at least 20% energy

2. Mitsubishi inverter as a master control system. Material length is accurate to within ± 3mm.

3. By adopting universal mold plate, Plastic forming machine for vacuum packing can save material 15%.

Main features:

1. This machine is semi-automatic, pull plastic sheet and move electric furnace are artificial. Other actions are done automatically.

2.The control board is near the operator, can be operated easily, greatly improve the efficiency of production.

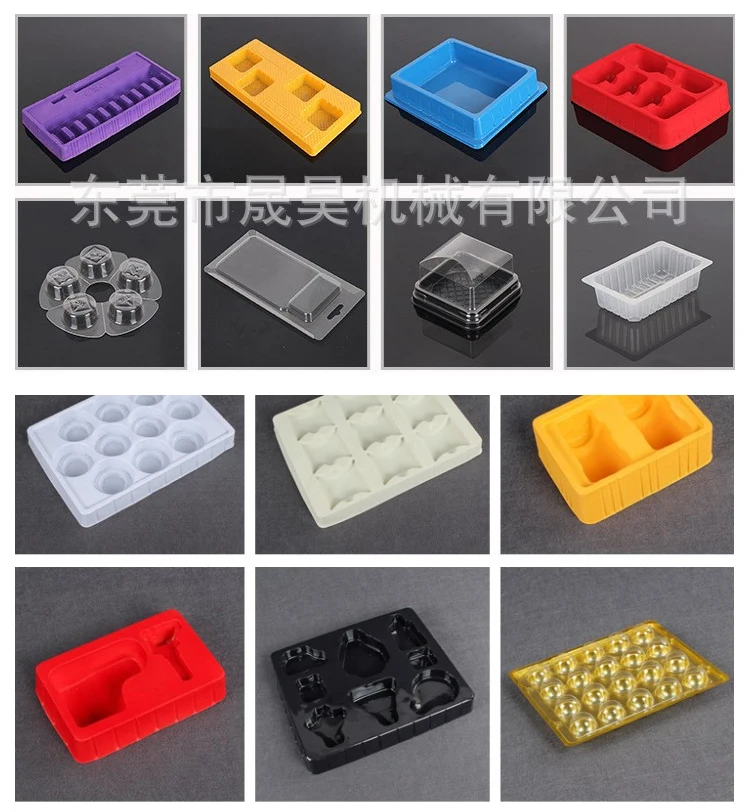

3.The far-infrared ceramic heating elements can control every single block heater temperature, easy temperature control.

4.The furnace is guided by bearing and guide pin, can move steady, enhance efficiency and furnace life.

5.The cooling fan is equipped with a wide mouth and spray device, to improve efficiency and product quality.

6.This machine can be equipped water spray cooling system if the blister is deep and complex.

7.This machine can form all kinds of blisters just replace mould.

| Product Attribute | |

| Model | CH-71-GSJ |

| Power Supply | 380V 3P 50/60HZ |

| Power | 27KW |

| Forming size | 710*1220MM |

| Max forming height | 200MM |

| Speed | 220-480Moulds/H |

| Thickness of material | 0.2-1.5MM |

| Machine Dimension | 7600*2500*2600MM |

| Machine Net Weight | 3000KG |

Reviews

There are no reviews yet.