Product Description

220V Round Carbide Saw Blade Grinder Mill Sharpener Alloy Saw Blade Rotary Angle Grinder Tool Manual Wood Working Machine

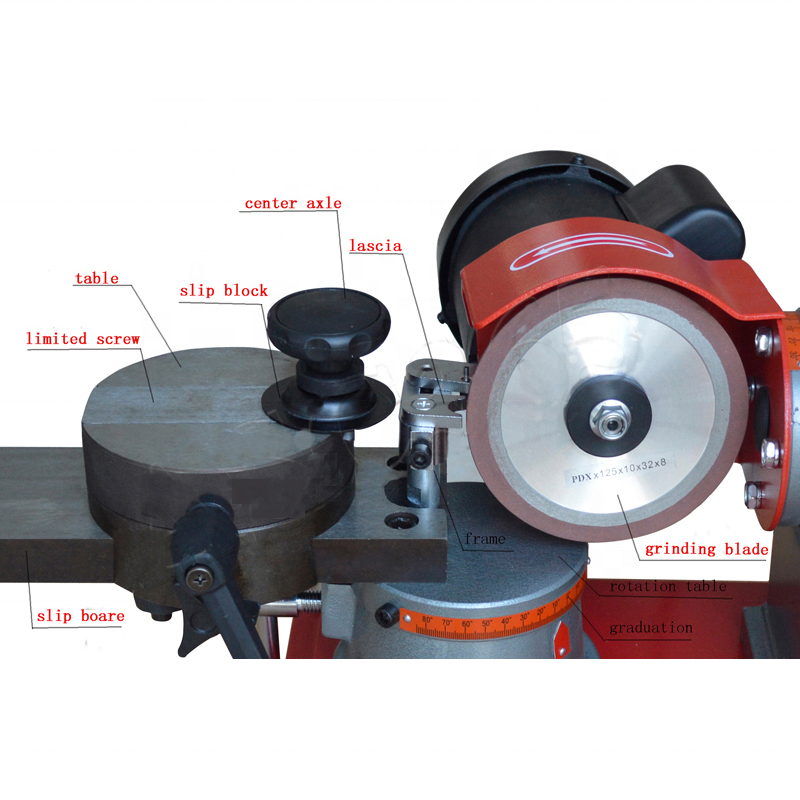

Method of operation:

First, loosing the fascia, then adjust the angle of grinding blade and fasten.

Second, adjusting of center axle.

- Rotating the center axle to the grinding blade.

- Pushing the center axle to the right.

- Installing the saw blade ,rotate the wheel and decide the position of grinding surface saw teeth.

- Rotating the rotation table to ensure the angle of grinding blade.

- The cross angle between the grinding surface and work surface is about 5.

Third, adjusting of positioning assembly.

- Adjusting the saw blade to the best grinding position, rotating the positioning frame and fascia.

- Adjusting positioning pin to the proper base of saw teeth and leave gap of grinding quantity, fasten the fixed screw.

Fourth, adjusting the center axle to the same gap of grinding quantity to the right.

Last, when all the parts are fastened, the saw blade supported with hand will be grinded.

Parameters

| Voltage | 250w/370w/550w |

| Speed | 2850 rpm |

| Diamond wheel | 125*10*32*2 mm |

| Packing size | 720*430*500 mm |

| Grinding range | 80-700 mm |

| Angle | Left 30° Right 40° |

| Adjust angle | -20° — +20 ° |

| Gorss weight | 30-32 kgs |

Company Information

Packaging & Shipping

Our Services

Reviews

There are no reviews yet.