1).The double paddle mixer is also named double spiral mixer, it is a new type of blending machine for compost, manure,concentrated fertilizer,additive premix,feed stuff,fodder, etc.

2). In order to improve the mixing uniformity; we use new rotor structure, the rotor and mixing chamber are so close to the minimum gap which can be adjusted to zero mm.

3). The double paddle mixer can reduce the material residues; with oil added channels inside, the overall structure is more reasonable with beautiful appearance, easy to operate.

Operation steps of double paddle mixer

When the dry powdery material is fed into the tank by the feeding nozzle, then the power transmission mechanism drives the spiral spindle rotation of the multi-group blades. By driving the passive helical shaft and the main shaft of the meshing transmission gear, the material is stirred and pushed to the tank and the wet section. After the material is pushed into the humidification section, the humidifier automatically sprays the material, and then the mixing section is fully stirred. When the material reaches the controllable humidity, it is removed from the outlet and enters the next process.

Technical Specifications of double paddle mixer

| Model | MSSJ-8030 | MSSJ-1050 |

| Power (kw) | 11 | 22 |

| Stirring shaft outer diameter (mm) | 420 | 650 |

| Reducer Model | ZQ350-31.5 | ZQ350-31.5 |

| Stirring Speed (r/min) | 35 | 35 |

| Dimension (mm) | 3700*800*750 | 6200*1300*1200 |

Horizontal fertilizer mixer is also named ribbon mixer, it is mainly used in chemical metallurgy, mining, building materials and other industries.

Advantages of horizontal ribbon mixer:

High stirring efficiency, small floor space. The spiral blade adopts special high – wear alloy.

The pan mixer adopts the reducer transmission; the rotation is stable, and the noise is low.

Feeding from top and discharging from bottom, which is reasonable structure.

The joint surfaces are tightly sealed and run smoothly.

Technical Specifications of horizontal mixer ribbon mixer

| Model | WJ-7015 | WJ-9015 | WJ-1530 |

| capacity | 2-3 tph | 3-5 tph | 10-15 tph |

| Motor Power (kw) | 7.5 | 11 | 22 |

| Stirring Chamber Thickness (mm) | 5 | 5 | 10 |

| Stirring speed (r/min) | 46 | 39 | 21 |

| Dimension (mm) | 2350*1000*1000 | 2350*1200*1000 | 3950*1720*2100 |

Rotary drum mixer machine adopts the operation method of feeding in positive rotation and discharging in reverse rotation, and the material is mixed and exported through special internal spiral mechanism and unique three-dimensional structure. The equipment has novel design and strong practicability; its feeding system does not store the material, and the mixing system is with high performance; electronic controlling system, with manual, automatic and compound settings, has the characteristics that the similar products do not have. The equipment is characterized by low price, small floor space, large output and even stirring, etc.

The vertical disc fertilizer mixer is a new kind of equipment which is improved on the basis of the original mixer. It is mainly used in organic fertilizer, compound fertilizer and power plant dust collector, which can also be used in chemical metallurgy, mining, building materials and other industries.

Advantages of disc type vertical mixer:

1) High stirring efficiency, small floor space. The spiral blade adopts special high – wear alloy.

The vertical disc fertilizer mixer adopts the reducer transmission; the rotation is stable, and the noise is low.

2) Feeding from top and discharging from bottom, which is reasonable structure.

The joint surfaces are tightly sealed and run smoothly.

1) Why Choose GATE Technology To Be Your Professional Supplier of Fertilizer Machine?

HENAN GATE HEAVY INDUSTRY MACHINERY TECHNOLOGY CO.,LTD is a leading and professional manufacturer of fertilizer machine and whole fertilizer production line in China. We are expertise in manufacturing high quality equipment for fertilizer production. We believe in "Great Achievements Through Excellence!" As for management principles, we insist on High Quality, Great Mission and Extraordinary Values.

2) What We Can Provide for Our Customers?

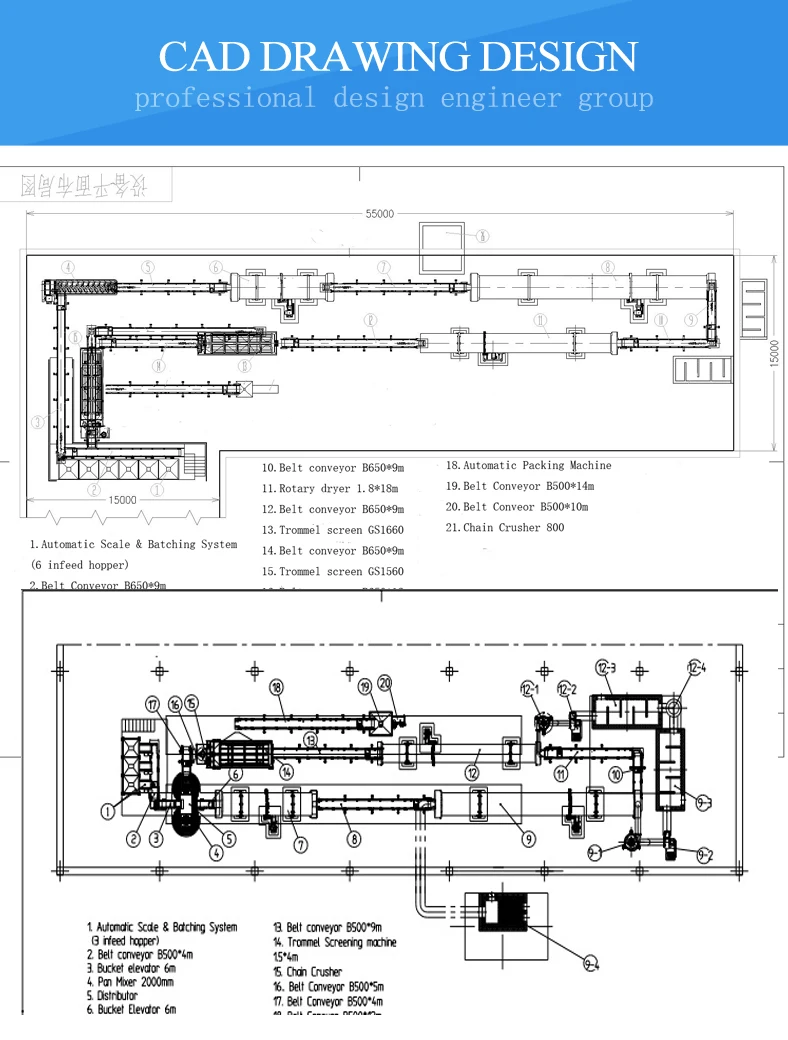

We can provide whole line of service, from technical consultancy, CAD drawing design, factory design, equipment production, shipment, and dispatch professional engineers to guide for installation and commissioning service, training your workers and technical stuff. Also, we have sufficient stock of spare parts, we can provide the spare parts at very fast speed and lowest cost.

3) What’s the Production Period of the Fertilizer Machine?

for single fertilizer machine, our production time is 7 days;and for whole fertilizer production line, our production time is no more than 30 days.

4) What’s the Quality Guarantee and Certifications?

all of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 18 months after shipment date.

5) Will Gate Technology Dispatch Engineers for Installation and Training Work?

Gate will dispatch engineers to help customers for the installation and commissioing work of the machines, and provide training service for all of our customers.

Reviews

There are no reviews yet.