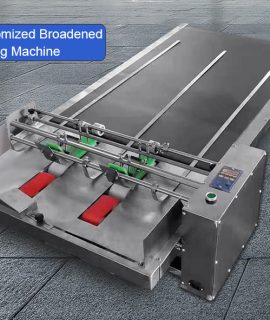

QP8-30 cable tie wire machine suitable diameter for 15-45 mm nylon cable wire tie twisting machine binding wire tying machine

Equipment overview:

This equipment is suitable for AC power cord, DC power cord, USB data cable, headphone cable, RCA cable, video cable, HDMI high-definition cable and other transmission lines twisted into bundles with rubber-coated iron core, and can also be used for other applications material used for rubber core sealing,like tape.

This machine can reduce the fatigue strength of employees, improve work efficiency, save ties and so on.The employee only needs to place the wire at the winding port, and then the wire is automatically wound, and then the wound wire is placed at the wire opening, and the machine can automatically tie the band.This machine can set the cable length, the number of turns, the number of winders, the speed of winding, and can count the output.

The machine adopts PLC program control and text display for parameter setting, and the operation is simple and convenient...

Touch screen control cable coiling and binding machien

high-definition cable and other transmission lines twisted into bundles with rubber-coated iron core, and can also be used for

other applications material used for rubber core sealing,like tape.

Button control cable coiling and binding wire

|

Serial number

|

Project name

|

Specifications

|

||

|

1

|

Voltage

|

AC220V

|

||

|

2

|

Power frequency

|

50HZ/60HZ

|

||

|

3

|

Rated power

|

Within 100W/300W

|

||

|

4

|

Winding size

|

Can be adjusted (50-200MM、50-300MM)

|

||

|

5

|

Winding speed

|

Can be set by yourself(1-25)

|

||

|

6

|

Number of coils

|

Can be set by yourself(1-999)

|

||

|

7

|

Scope of application

|

Tie length

|

Max diameter range

|

|

|

8

|

QP8-30

|

75-140mm

|

Φ05-30mm

|

|

|

9

|

QP18-45

|

120-220mm

|

Φ18-45mm

|

|

|

10

|

QP40-80

|

220-300mm

|

Φ40-80mm

|

|

|

11

|

Number of ties

|

Can be set by yourself(Suggest 3-5)

|

||

|

12

|

Tie speed

|

Can be set by yourself(0.6s/times)

|

||

|

13

|

Cable tie material

|

Coated iron core(Best PE material)

|

||

|

14

|

Protective device

|

Fuse, fault alarm shutdown

|

||

|

15

|

Dimensions(L*W*H)

|

485x420x340mm/550mm*610mm*420mm

|

||

|

16

|

Total weight

|

65Kg

|

||

Cable extrusion production line

IApplication

This production line is mainly applicable to wire & cable insulation and outer sheath extrusion. Insulation materials: PVC, PE, XLPE and so on.

Ⅱ Main Technical Parameters

1.Production range

Conductor diameter:φ1.5mm – φ8mm

Finished OD: φ2.5mm – φ10mm

2.Extrusion capacity Max-130kg/h

3.Motor power 30kw / 4-pole Motor (Variable Frequency Motor)

4.Screw speed 80rpm

5.Screw L/D 25: 1 (compression ratio: 1/3.2)

6.Production line speed Max300m/min

7.Heating power 16kw (4-section blower heating, 2-section heating at extruder head)

8.Pay-off spool specification 630mm(PNφ400-φ630mm)

9.Take-up spool specification: 630mm (double spool)

10.Voltage class 380V/50Hz

11.Equipment center height 1000mm

12.Production direction Left pay-off stand and right take-up stand

13.Complete machine capacitance 55kw

Shanghai Qi Pang Industrial Co., LTD was established in 2013. Our company is a high-tech enterprise that develops and make the series polished shaft rolling ring drive and wire straightener earliest in China. The company is located in the JiaDing, Anting auto city, which is the world financial center in Shanghai. It is very convenient.

We always adhere to the talent oriented and honest business principles since our company established . Our company will continue to attract talents in various fields and advance foreign advanced technology to make our products have a high quality and precision. Our company developed a new type machine in 2015. It is a new type of machine : Frequency Take-up machine.

We always adhere to the principle of quality first, credit first and customer first. We sincerely welcome our old and new customers to cooperate and create a better future.

1. Our products: rolling ring drives, wire straightener, take-up machine

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

Q1: Are you a factory or trading company?

We are a factory . We can promise you a short lead time and best price if you purchase our machine. We also have our own trading department.

Q2: How does the factory ensure products quality?

With Nearly 16 years experience in manufacturing winding machine, we have our own technology develop department and testing department.

Quality is the first priority. We have strict purchasing system to ensure the quality of spare parts. We have experienced workers to assemble and test machine.

Q3:How about your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

Q4: What are your payment terms?

100%TT or prepaid 50% , balance 50% before shipping.

Q5: How can I get my order? How can I know you sent the goods?

We will send the goods by UPS, DHL, FedEx or sea shipment. After we sent the goods, we will give you the tracking number or other relative files for checking.

Q6 : Will you send the installed machine or machine parts?

We will install the machine and test the machine before delivery. And the machine can be used directly after receiving the machine.

My Tel/Wechat/Whatsapp/Skype:+86 13472640466

Reviews

There are no reviews yet.