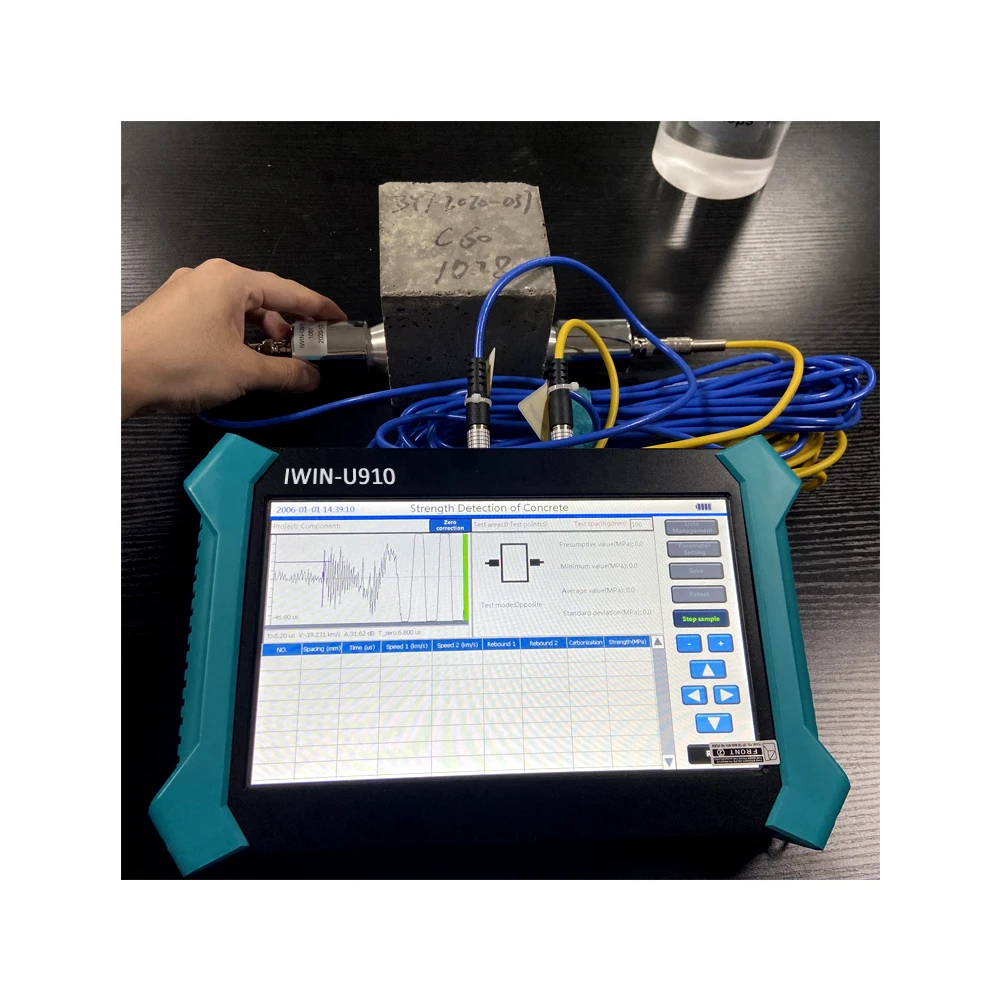

Product Display

ultrasonic pulse velocity tester

U910 / U920 ultrasonic pulse velocity tester used for structural concrete compressive strength, crack depth, crack width and defect detection;Diaphragm wall integrity testing, which integrates five functions of pile testing, ultrasonic rebound comprehensive method for strength measurement, defect detection, crack sounding and width measurement. Geological exploration, rock integrity, weathering evaluation test; mechanical properties of non-metallic materials such as rock mass and concrete.

|

Product Model

|

IWIN-R800

|

||||||

|

Standard number

|

ASTM A615/A ,615M,DIN 488

|

||||||

|

Rebar diameter setting range (mm)

|

6mm~50mm

|

||||||

|

Small range

|

1~90mm

|

||||||

|

Large range

|

1~210mm

|

||||||

|

Maximum Allowable Error of Protective Layer Thickness

|

±1(mm) 1~59mm

|

||||||

|

±2(mm) 60~69mm

|

|||||||

|

±4(mm) 70~119mm

|

|||||||

|

±6(mm) 120~210mm

|

|||||||

|

Applicable Scope of Diameter Estimation

|

6mm~32mm

|

||||||

|

Maximum error of diameter indication

|

Specification (+1)

|

||||||

|

Profile measurement function

|

YES

|

||||||

|

Mesh measurement function

|

YES

|

||||||

|

Waveform measurement function

|

YES

|

||||||

|

Probe self-calibration

|

YES

|

||||||

|

Host parameters

|

Screen size: 2.8 inch resolution: 240 x 320

|

||||||

|

Volume: 220 x 93 x 110 mm weight: 0.6 kg

|

|||||||

|

Data transmission mode

|

TF card, wireless cloud transmission (optional)

|

||||||

|

Power supply

|

lithium battery

|

||||||

|

storage capacity

|

2000 Components*1000 Measuring Points

|

||||||

|

Working environment requirements

|

Temperature: -10 C to+40 C Humidity: <90% RH

|

||||||

|

Other requirements

|

There is no corrosive gas in the air.

No strong electromagnetic interference. There should be no large vibration and shock. Instruments to avoid direct sunlight |

||||||

Products Description

|

Features

|

Features

|

|

|

1

|

The thickness detection mode displays the position of the reinforcing bar intuitively and accurately, and simultaneously displays the thickness and the spacing of the reinforcing bars;accurately, and simultaneously displays the thickness and the spacing of the reinforcing bars;

|

|

|

2

|

The thickness detection mode can automatically store the thickness and spacing, and the detection efficiency is greatly improved;

|

|

|

3

|

The waveform scanning mode visually displays the distribution of steel bars, which makes the detection and analysis of dense steel bars more intuitive;

|

|

|

4

|

The waveform scanning mode simultaneously displays the determined thickness and spacing of the protective layer of the steel bar;

|

|

|

5

|

It can detect the middle position of two steel bars, aiming frame and indicator light, which is convenient for punching and core;

|

|

|

6

|

The instrument automatically stores the calibration value to achieve fast measurement,eliminating the trouble of each calibration;

|

|

|

7

|

Boundless mesh/section scanning, waveform scanning can measure up to 6m in length;

|

|

|

8

|

TF card storage, large capacity, intuitive and convenient to transfer;

|

|

|

9

|

2.8-inch high-resolution color LCD screen;

|

|

|

10

|

One-piece design, small size, light weight, easy to carry;

|

|

|

11

|

PC professional data analysis software, data processing and report generation is easy to complete;

|

|

Reviews

There are no reviews yet.