Technical parameter of biomass rotary dryer :

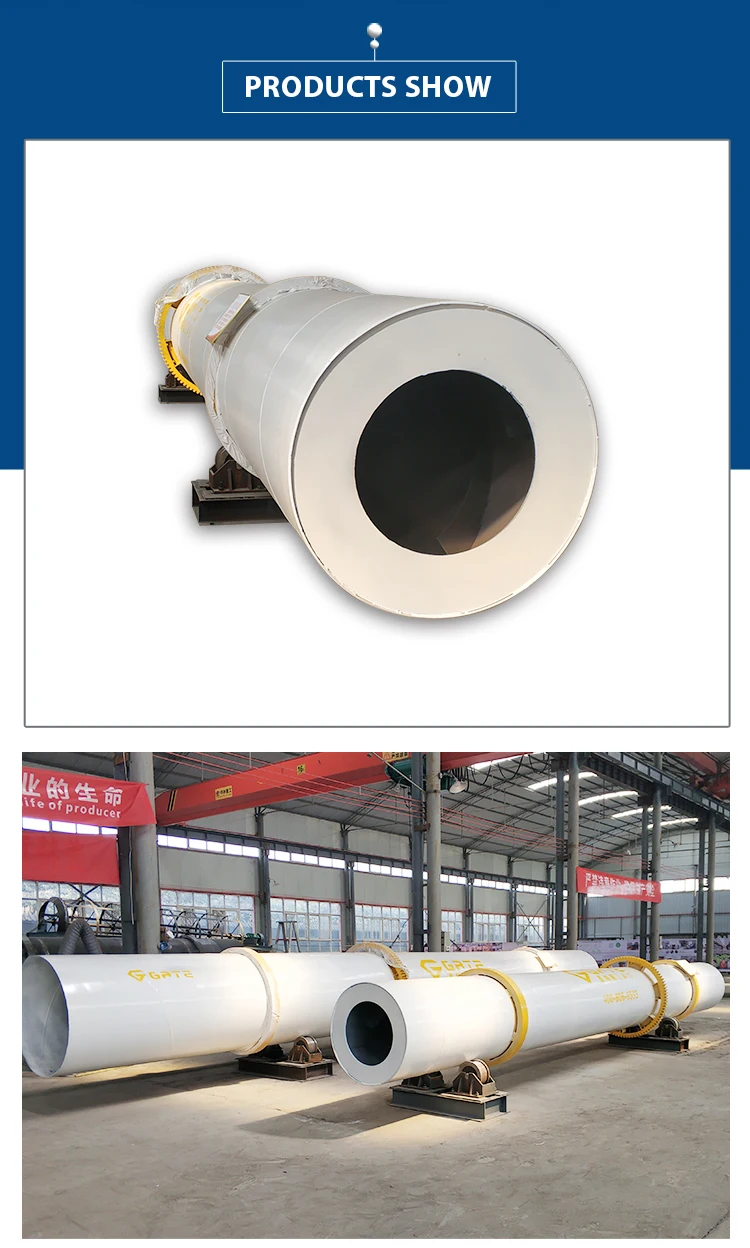

biomass rotary dryer used in fertilizer industry, also known as rotary dryer for organic fertilizer making machine. It is widely used in building materials, metallurgy, chemical industry, cement industry to dry slag, clay and other materials.

Thebiomass rotary dryer diagram is mainly composed of a rotating body, a lifting plate, a rotating device, a supporting device and a sealing ring. It has the characteristics of reasonable structure, excellent production, high product, low energy consumption and convenient operation.

|

Model

|

Rotary speed(r/min)

|

Powder (kw)

|

Capacity (t/h)

|

Weight (t)

|

|

Ф800×10000

|

3-8

|

4

|

0.8-2.5

|

4.5

|

|

Ф1000×10000

|

3-8

|

5.5

|

1.0-3.5

|

5.6

|

|

Ф1200×10000

|

3-8

|

7.5

|

1.8-5

|

14.5

|

|

Ф1200×12000

|

3-8

|

11

|

2-6

|

14.8

|

|

Ф1500×12000

|

2-6

|

15

|

3.5-9

|

17.8

|

|

Ф1800×12000

|

2-6

|

18

|

5-12

|

25

|

|

Ф2200×12000

|

1.5-6

|

18.5

|

6-15

|

33

|

Composition Analysis of Cow Manure Organic Fertilizer

Cow dung contains 14.5% of organic matter, 0.30-0.45% of nitrogen, 0.15-0.25% of phosphorus, and 0.10-0.15% of potassium. It is a valuable resource that can be used as a source of soil fertilizer by the planting industry.The organic matter and nutrient content are low in various livestock, fine in texture, high in water content, slow in decomposition and low in calorific value, and it is a late-acting fertilizer. Cow manure itself has much less nutrient content than chicken manure and pig manure (nitrogen, phosphorus)

The content of potassium is small. In addition, the cow manure is cold organic fertilizer, and the decomposition rate is slower than chicken manure and pig manure. Therefore, the fertilizer efficiency is much slower than chicken manure and pig manure.

Customer service:

In the sale of products, the interests of customers is our first consideration, our pursuit of fine service, from pre-sales advice, enthusiastic service to the sale of products to promote, we all require fine in the fine. Powerful design and development team, occasional visits, strict quality assurance and prompt after-sales service, each link has made careful arrangements to solve a series of customer worries.

Pre-sale service:

1. accept customer inquiries, according to customer demand, determine the scale of operation, provide plant construction program;

2. to provide customers with project design, process design, suitable for your purchase of machinery and equipment program, in a timely manner to provide customers with relevant technical documents;

3. according to your special requirements, design products for your training technical operators preliminary design and construction design.

After Sale service:

1. the company sent technical personnel to the scene to guide the installation of equipment, commissioning site and train operators

2. 24 hour all weather phone service, holiday service as usual.

3. establish customer files and track, as follows:

Establish customer files, master the place of sale equipment, operation status, return visit time and contact information; assign special after-sales service personnel to the site to instruct customers to install and debug. After the complete set of equipment has been installed, special technical personnel shall be sent to assist the customers on site for free, until the customer is satisfied.

4. the hotline daily information and processing of detailed registration, custody, timely handling customer problems.

5. Inform the customer of the equipment that has been in warranty period and inform the equipment maintenance details on a regular basis.

A. Does GATE Professional manufacture of biomass rotary dryer?

HENAN GATE HEAVY INDUSTRY MACHINERY TECHNOLOGY CO.,LTD is a leading and professional manufacturer of fertilizer machine and whole fertilizer production line in China. We are expertise in manufacturing high quality equipment for fertilizer production.

B. What do you Provide for your Customers about biomass rotary dryer?

We can provide whole line of service, from technical consultancy, CAD drawing design, factory design, equipment production, shipment, and dispatch professional engineers to guide for installation and commissioning service, training your workers and technical stuff. Also, we have sufficient stock of spare parts, we can provide the spare parts at very fast speed and lowest cost.

C. What’s the Production Period of the biomass rotary dryer?

for single fertilizer machine, our production time is 7 days;and for whole fertilizer production line, our production time is no more than 30 days.

D. What’s the Quality Guarantee?Do you also accept the Third-party Inspection?

all of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 18 months after shipment date.we also accept the Bureau Veritas or other third-party inspection.

E. How about the Installation and Training Work?

We will dispatch engineers to help customers for the installation and commissioing work of the machines, and provide training service for all of our customers.

Reviews

There are no reviews yet.