Products Description

Product features

double parallel wires (two electronic wires can be processed) cutting, bifurcation, single-head peeling and finishing, single-head tinning;

1. High-precision accessories, original AirTAC imported cylinders, Taiwan silver screw guide, PLC control, color LCD touch screen control, can be equipped with multiple configurations, suitable for double parallel lines, double electronic lines, single end, single end dip tin ; There are automatic and manual operation modes, the blade is refined with Swedish ASP60 high-speed powder steel,

2. One-year warranty (2500 hours) for mechanical parts, lifetime maintenance, except for vulnerable parts;

3. Free one-stop service of training, installation, debugging, maintenance and repair is provided.

Cut off the wires, peel off the two ends or split the wires at both ends, one end is single, one end is tinned;

1. High-precision accessories, original AirTAC imported cylinders, Taiwan silver screw guide, PLC control, color LCD touch screen control, can be equipped with multiple configurations, suitable for double parallel lines, double electronic lines, single end, single end dip tin ; There are automatic and manual operation modes, the blade is refined with Swedish ASP60 high-speed powder steel,

2. One-year warranty (2500 hours) for mechanical parts, lifetime maintenance, except for vulnerable parts;

3. Free one-stop service of training, installation, debugging, maintenance and repair is provided.

Cut off the wires, peel off the two ends or split the wires at both ends, one end is single, one end is tinned;

|

Cutting speed

|

About 8000 pieces /hour

|

|

Processing capacity

|

100mm length, 2000 finished products/H

|

|

Adapted wire

|

AWG#18—-AWG#28 or corresponding double parallel wires, DC terminals, red and black wires, etc.

|

|

Cutting length

|

20mm-9999.99mm

|

|

Bifurcation length

|

>20mm or more

|

|

Cutting accuracy range

|

0.01mm+cutting length*0.2%

|

|

Stripping length

|

0.1mm—12mm

|

|

Crimping capacity

|

standard 2.0 ton terminal machine

|

|

Adapt to mold

|

OTP conventional horizontal mold or straight mold

|

|

Detection device

|

presence of wires, terminals, air pressure detection, crimp detection, etc.

|

|

Power supply

|

0.5Mpa (5kgf/cm) about 200NL/Min, requiring stable and dry air

|

|

Compressed air

|

30mm (40mm, 50mm optional)

|

|

Size

|

600W*700L*1500Hmm

|

|

Weight

|

about 240KG

|

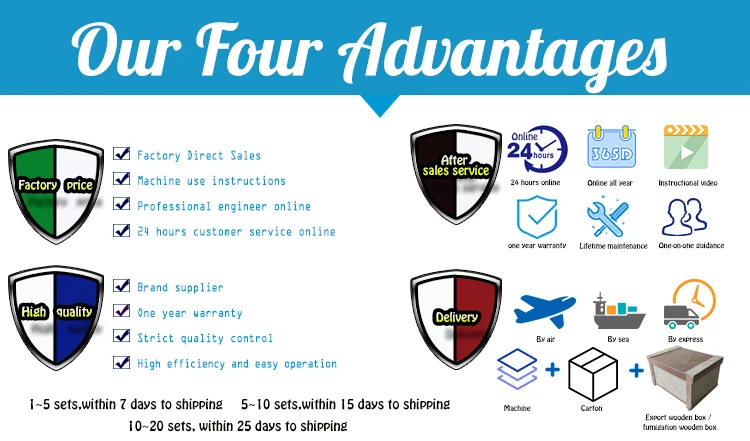

Packaging & Shipping

|

Packaging

|

||

|

Size

|

700mm(L) * 800mm(W) * 1650mm(H)

|

|

|

Weight

|

350KG

|

|

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is

too tigher,we will use pe film for packing or pack it according to customers special request. |

|

Company Information

Our Services

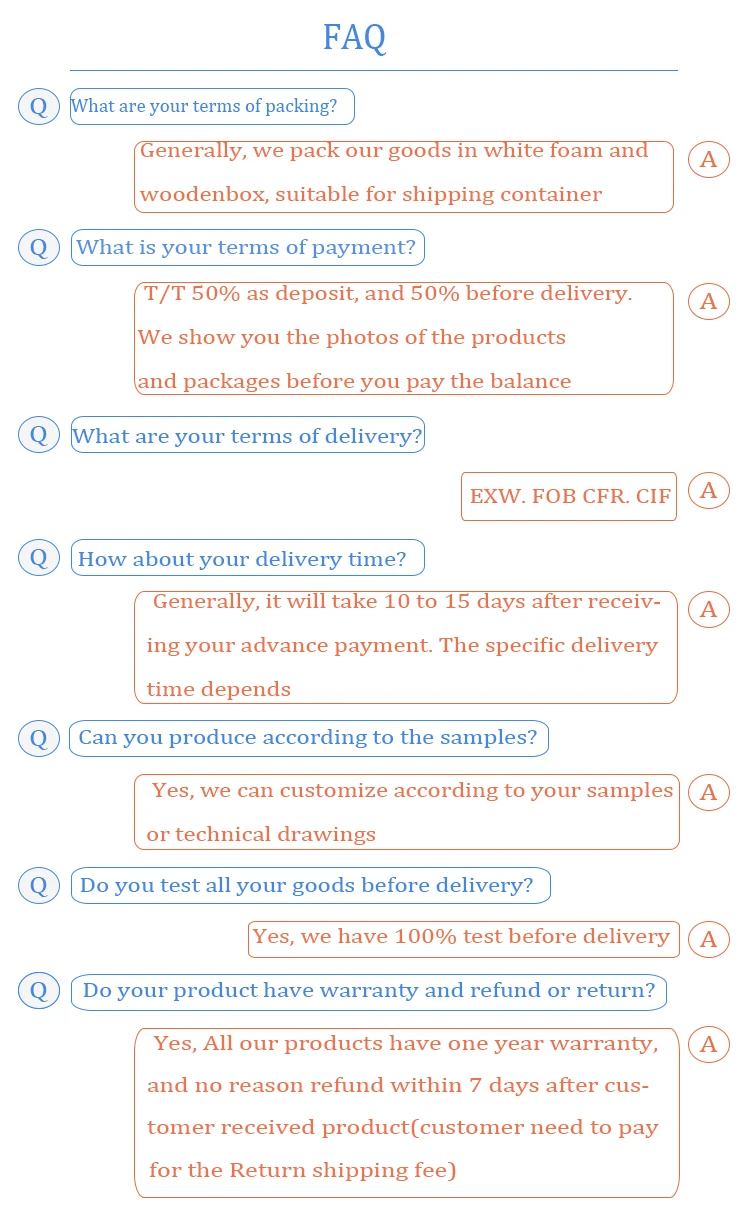

FAQ

Reviews

There are no reviews yet.