Drinking Water Treatment Filter Ultrafiltration Machine Ultrafiltration Water Purification Machine

The reverse osmosis device is an equipment to purify the saltine water with the action of pressure difference of semi permeable membrane. It is called reverse osmosis, as it is counter to natural penetration direction. Different materials have different osmotic pressures. The reverse osmosis method to adopt larger osmotic pressures is used to obtain the purpose to separate, extract, purify and condense.

More than 97% soluble salts and 99%glues, microbe, particulate and organic substances and etc can be removed with the reverse osmosis. It becomes the most idea equipment for the modem program of pure water, hyper pure water, and airspace water. The remarkable characteristics of the equipment are shown as lower energy consumption, no pollution, simple techniques, high water quality, easy operation and maintenance.

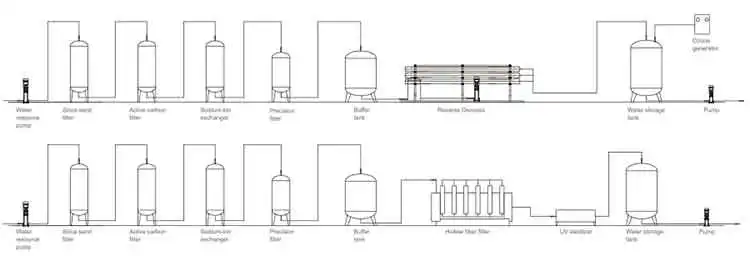

Standard RO System water treatment plant Process:

Raw water pump – Sand filter – Carbon filter -Cartridge filter – High pressure pump-RO membrane host

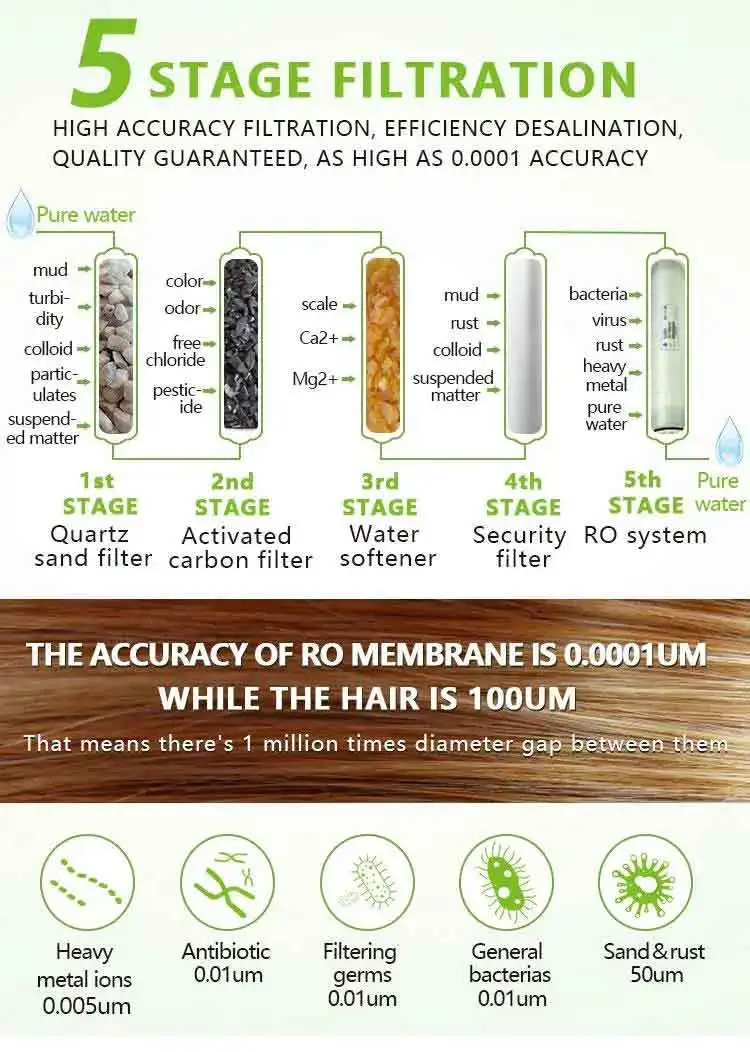

1. Silica sand filter is the equipment of hermetically sealed chamber made of 1 Cr18NiTi stainless steel which is set inside gritted rod,therefore get filltrated and clean.The equipment is widely used in petroleum industry,pharmaceutical industry wine-making industry and beverage industry.It is a ideal equipment to produce high quality water.

2. Active carbon filter.This filter is designed for drinking water treatment.It can clear away alien colour and foreign substance from the water and can remove heavy metal such as mercury,lead,cadmium,zinc,iron,manganese and Chromium,and hydrogenate,sulphide,small amount of remaining chlorine and so on.The filter is the ideal equipment for drinking water,foodstuff,beverage industries.

3. Sodium ion-exchanging device.The exchanging device is for reducing the hardness of hard water.Raw water goes through the exchanger from top to bottom,to be softened by the sodium ion-exchanger inside the device.The positive ions of Magnesium and Calcium are exchanged with that of sodium.Then the raw water becomes soft water containing very few ions of Magnesium and Calcium.The soft water can be used for feeding water of boiler and for some industrial uses.Due to its highly dissolving ability in water,sodium ions will not form hard sediment in the boiler and can be easily removed.Raw water shall be filtered and settled with almost on suspended before coming into the ion-exchanging device.After being softened in the device,the residual hardness shall be less than 0.03mg equivalent/L.

4.The Reverse Osmosis Device is an equipment to purify the saline water with the action of pressure dillerence of semi-permeable membrane.It is called reverse osmosis,as it is counter to nalural penetration direction.Different materials have different osmotic pressures.The reverse osmosis method to adopt large OsmOtic pressures is used to obtain the purpose to separate,extract,purify and 99% glues,microbe,particulate and organic substances and etc.Can be removed with the reverse osmosis.It becomes the most ideal equipment for modern program of pure water,hyper pure water,and alrspace water.The remarkable characteristics of the equipment are shown as lower energy consumption,no pollution,simple technics,high water quality,easy to operation and maintenance.

5. Hollow-fiber ultrafilter.This ultrafilter adopts dissymmetrical semipermeable film which is made from macromolecule material with special process.The raw liquid flows under pressure,inside or outside the the film.The macromolecule substance and colloid particles in the raw liquid are clogged at the film surface and are brought away by circulating raw liquid.Then the raw liquid becomes inspissated,furthermore,the subtance in liquid is separated,concentrated.

1. Food and Beverage

2. Tube and Micro Circuit manufacturing

3. Pharmaceuticals

4. Hotels & Resorts

5. Hospitals, Mineral Water Processors

6. Power Generation

7. Electronic Component manufacturing

8. Semi conductors

1. Running stablely, high desalination and recovery rate.

2. Easy to operate and small maintenance workload

3. Compact structure and saves installation place.

4. Highly efficient and low energy consumption.

5. No secondary pollution and low operation cost.

| Model | Flow rate (L/h) | Power(KW) | Water use efficiency | RO membrane | Dimension L X W X H(mm) |

| RO-500L | 500 | 1.5 | ≥ 50% | 4040 | 1650X630X1800 |

| RO-750L | 750 | 2.5 | ≥ 50% | 4040 | 1870X630X1850 |

| RO-1000L | 1000 | 2.5 | ≥ 50% | 4040 | 1870X650X1850 |

| RO-2000L | 2000 | 3.5 | ≥ 50% | 4040 | 2440X650X1750 |

| RO-3000L | 3000 | 4 | ≥ 50% | 4040 | 2440X620X1850 |

| RO-5000L | 5000 | 7.5 | ≥ 50% | 8040 | 2000X900X1800 |

| RO-6000L | 6000 | 9.5 | ≥ 60% | 8040 | 3000X900X1800 |

| RO-8000L | 8000 | 13.5 | ≥ 60% | 8040 | 3000×900×1800 |

| RO-9000L | 9000 | 14 | ≥ 60% | 8040 | 4000X900X1800 |

| RO-10T | 10T/H | 19 | ≥ 60% | 8040 | 3000X900X1800 |

| RO-12T | 12T/H | 19.5 | ≥ 60% | 8040 | 4000X900X1800 |

| RO-15T | 15T/H | 23 | ≥ 60% | 8040 | 4000X900X1950 |

| RO-20T | 20T/H | 28 | ≥ 60% | 8040 | 5000X900X1950 |

| RO-30T | 30T/H | 55 | ≥ 60% | 8040 | 7000X900X1950 |

Reviews

There are no reviews yet.