NL-5557 Anti-Spark System

Using high sensitivity America-Imported anti-spark thyratron tube, which is useful for protect mould and work-piece once machine over creent.

TOSHIBA 7T85 Oscillation Tube

Using TOSHIBA original imported oscillation tube, more powerful output power and durable than other brand.

AirTac Air System

Adopting famous brand AirTac air system, greatly make the machine pressure working precisely.

1. Safety device

When the current exceeds its limit, the overload relay functions automatically to protect oscillation tubes and rectifier. Frequency deviation caused by misoperation is also prevented.

2. Strong Foot Pedal

Machine using a special designed mechanism, the maximum pressure of foot pedal can reach up to 400KGS so as to meet most operating conditions. The high quality components make these machines work very smoothly and precisely.

3. Easily Adjustable Tuner

Machine output power can be adjusted at the tuner according to electrode size and material thickness. In addition, other control devices and special electrical circuits have cut down required welding time considerably to raise the machine productivity.

4. Jamming Prevention Device

High frequency welding machine equipped with frequency stabilizer and high frequency magnetic leakage suppressor, this device provide leakage of electron magnetic radiation to avoid jamming other electrical instruments such as television and radios etc.

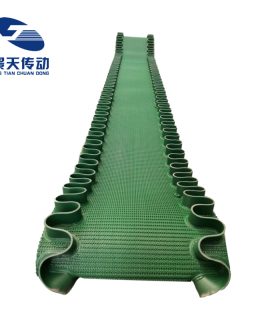

Final products done with HF welding

Common products manufactured with HF welding method are tarpaulins, tents, ceilings, advertising outdoor banners, waterbeds, inflatable boats, drip and blood bags, tensile structures, conveyor belts, rain clothing, etc.

What materials can be HF welded

The material most common in high frequency welding in PVC (something called simply vinyl) and PU (polyurethane). The material can be thick or thin, reinforced or coated. It cab also be plain, coloured or structure/patterned.

Polyvinylchlorde (PVC) and polyurethanes (PU) are the most common thermoplastics that are weldabele by HF also it is possbile to perform HF welding on other types of materia inculding naylon, PA, ABS, modified TOP, PETG, but particular attention should be pay on working parameters. HF welding is not suitable for PTFE, polycarbonte, polystyrne, polyethylene or polypropylene. Howeve, a special type of mixed fabrics have been produced recently, which have the capability to be HF welded.

Our Company:

Dongguan Chenghao Machinery Co., Ltd. has been committed to R&D, production and sales of the plastic welding field ever since its establishment in 1995.

We are professional designer and manufacturer of High Frequency Welding Machine, Ultrasonic Plastic Welding Machine, Blister Forming Machine, Tube Sealing and Filling Machine and other Packing Machine with over 10 years.

We welcome both new and regular customers at home and abroad to visit us and cooperate with us to achieve mutual profits and create a better future. We are convinced that your partnership with us can help your business scale a new high.

The sea admits hundreds of rivers for its capacity to hold. Since its inception, CHENGHAO MACHINERY always pay attention to the cooperation with famous enterprises both at home and abroad; By the network, optimize enterprise resources and integrate industry technology, constantly temper the team to build an elite team and provide high quality product.

Since its inception, CHENGHAO MACHINERY has been devoted to optimization and integration of developing, producing, sealing, and application of technology of ultrasonic machinery. After almost twenty years of unremitting efforts, CHENGHAO MACHINERY with high quality products, excellent technical support and perfect after-sales service has established a good reputation among the customers, and also gains a number of provincial and national honnors.

5KW Double Head High Frequency Welding Machine

CH-5KW-STQY

5KW Shuttle Tray High Frequency Wedling Machine

CH-5KW-SDHT

8KW Round Table High Frequency Welding and Cutting Machine

CH-8KW-YPRD

Q: Are you trading company or manufacturer ?

A:Yes, We are factory, all machine is made by ourself and we can provide customize service according to your requirement.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q:What about your warranty?

A:Our warranty is 1 year, all machine part can be replaced for free within 1year if broken(not including man made).

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Pre-sale services:

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

4. Personal call or visit are warmly welcome.

Sale of services:

1. We promise honest and fair, it’s our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1. Where to buy our products for 1 years warranty and life long maintenance.

2. 24-hours telephone service.

3. A large stock of components and parts, easily-worn parts.

Reviews

There are no reviews yet.