cbd-oil-extract-machine extracion cbd thc oil extract small cbd oil making machine

ر.س75,349.31

Product Description

TOPTION brand TOP-C series flat-type large flip lid, top discharge centrifuges are filter type centrifuges, which has absolute advantages such as box-type flat-plate, damping and anti-vibration, flip lid sealing, and manual upper discharge.

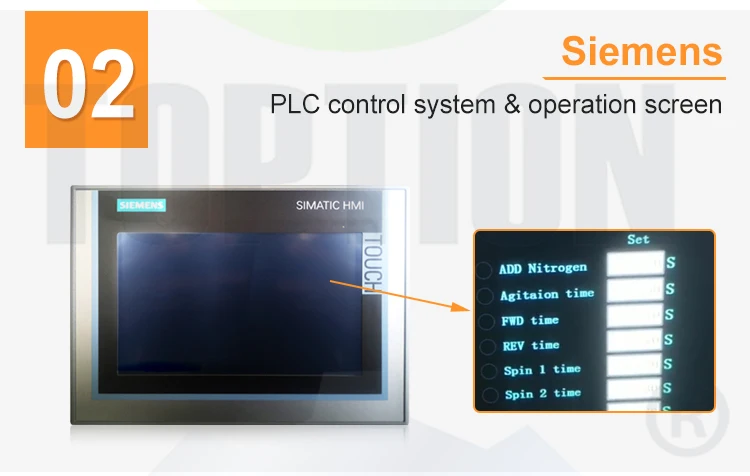

This series centrifuges are controlled by PLC program, and the stepless speed regulation of the centrifuge is realized through the frequency converter. The energy-saving braking system is used to consume the energy generated during the stopping process, so as to achieve a smooth stop of the machine.

According to the preset program, the operations of material charging, soaking with ethanol, adding condensing agent to keep warm, stirring and mixing, high-speed deliquoring washing, spin-drying, and discharging are performed at the corresponding speed.

TOP-C series centrifuges are specially used for the separation and extraction of ethanol from plant raw materials. Put the dried plant raw materials in a bag and wash in two directions by immersing in ethanol. After washing, the plant material is dried with medium strength even high-speed spin drying, so as to remove ethanol as much as possible from the plant material, the ethanol washing solution is collected in a container for further processing.

This type centrifuge has a high degree of automation, large processing capacity, convenient operation and maintenance, and can realize remote control. Its special structure allows the working temperature to be as low as -80℃, prevents the volatilization of ethanol, and improves production efficiency.

|

Main parameters

|

TOP-C15

|

TOP-C30

|

TOP-C50

|

TOP-C110

|

TOP-C160

|

TOP-C220

|

||||||

|

Vessel diameter(inch)

|

12

|

18

|

24

|

32

|

40

|

47

|

||||||

|

Vessel volume(L)

|

18

|

48

|

110

|

251

|

393

|

565

|

||||||

|

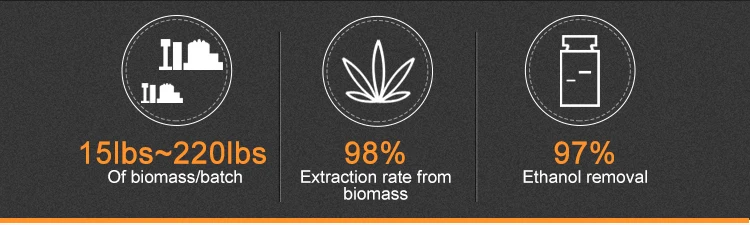

Biomass/batch(lbs)

|

15

|

30

|

50

|

110

|

160

|

220

|

||||||

|

Alcohol solvent (L)

|

57

|

110

|

201

|

377

|

546

|

745

|

||||||

|

Standard Max speed(r/min)

|

3000

|

2000

|

1500

|

1000

|

900

|

700

|

||||||

|

Optional 1: speed

|

4000

|

3000

|

2000

|

1500

|

1200

|

1000

|

||||||

|

Main motor power (kw)

|

2.2/3

|

3/4

|

5.5/7.5

|

7.5/11

|

11.0/15

|

18.5/22

|

||||||

|

Vessel load-bearing (lbs)

|

25

|

50

|

100

|

320

|

450

|

540

|

||||||

|

Dimension (L*W*H)mm

|

850*610*900

|

980*680*1000

|

980*680*1000

|

1700*1200*1500

|

1970*1400*1500

|

2200*1700*1500

|

||||||

|

Machine weight(kg)

|

300

|

500

|

800

|

1400

|

1900

|

2500

|

||||||

|

Optional functions are as follows:

|

||||||||||||

|

Optional 1

|

Speed can be increased, depending on customer needs.

|

|||||||||||

|

Optional 2

|

Fully automatic type: Replace all electric valves, electric encoders, gas control cabinets, etc. For specific technology, please

refer to the “Process Flow” full automatic type below. |

|||||||||||

|

Optional 3

|

UL standards for all electrical appliances, current standards of electrical appliances are CE standard.

|

|||||||||||

|

Optional 4

|

EX external split type PLC operation screen. Convenient for higher level explosion-proof requirements, electric control cabinet and PLC distribution type, all electric control cabinets are placed outside, not in the factory.

|

|||||||||||

|

Optional 5

|

Whole machine use 316L material.

|

|||||||||||

|

Optional 6

|

Surface passivation.

|

|||||||||||

Reviews

There are no reviews yet.