UL790 UL 1730 ASTM E108 For Solar Cell Spread

Description:

This equipment virtually simulates an external fire to evaluate the resistance of the roof and other physical elements of fire, in order to qualify for the flame spread experiments(A~C class), in case of A 1.82m, B 2.4m and C 3.9m. It is an equipment to displacement of the testing material and the exposure and falling of the roof structure.

Standards:

UL 1730 : Smoke Detector Monitors and Accessories for Individual Living Units of Multifamily Residences and Hotel/Motel Rooms: Electrically operated annunciators for residential type smoke detectors.

UL 790 : Standard Test Methods for Fire Tests of Roof Coverings

IEC 61730-2 Annex.A: Fire Tests, Spread-of-Flame and Burning-Brand Tests

ASTM E 108-04: Standard Test Methods for Fire Tests of Roof Coverings

KS C IEC 61730-2 Annex .A: Fire resistance test, Spread-of-Flame and Burning-Brand Test.

Specification:

A Test Room to install the equipment

– The material should consist of minimal fire-proof material with sandwich panels including fireproof urethane.(Suggests a sandwich panel consisting of Glass Wool)

– Measures : 7,000(W) × 4,000(D) × 4,000(H) or greater.

Test Deck

Eaves and cornice

Air Ducts

Non-Combustible Board

Auto Ignition System

7-Segment timer mark

Velocity Measurement System

DAQ Control Unit

PC Operation • Adequate for removal of moisture in compressed air or nitrogen gas.

Power Voltage : AC 380V 3-Phase, 50/60Hz, 50A0 (h) Mm

Parameter:

| Air Velocity: | 19±8 Km/h |

| Measures : | 7,000(W) × 4,000(D) × 4,000(H) or greater |

| Class A, B : | 760 ±28°C(1400 ±50°F) – 21,000 ~ 22,000 Btu/min(369 ~ 387 KWh) |

| Class C : | 704 ±28°C(1300 ±50°F) – 18,000 ~ 19,000 Btu/min(316 ~ 334 KWh) |

| Power Supply: | AC 380V 3-Phase, 50/60Hz, 50A0 (h) Mm |

| Weight | 380KG |

Features:

Slop of Deck Plate can be easy to control by Air Cylinder.

Fire resistance board attached eaves of Test Deck.

Using auto control valve for adjusting temperature condition by Class.

– Class A, B : 760 ±28°C(1400 ±50°F) – 21,000 ~ 22,000 Btu/min(369 ~ 387 kWh)

– Class C : 704 ±28°C(1300 ±50°F) – 18,000 ~ 19,000 Btu/min(316 ~ 334 kWh)

Each gases supplied to Burner follows up different measurement and control way.

– LNG: Using MFM, accuracy flow measurement (Flow control is controlled by Auto Control Valve)

– LPG: Using MFC, accuracy flow measurement and control.

Inverter System gives maintain Air Velocity: 19±8 km/h(5.5m/sec) on the Test Deck.

Auto ignition way is adapted for test and ignite in the same time.

Guide Plate is attached in the Air Duct because of protecting of flow turbulence which is supplied to Test Deck.

Slop adjustment panel for adjusting of Air flow direction is installed in the Air Duct.

Individual burner is installed for burning-brand test.

Thermocouple is installed on 58.7mm from top of burning-brand burner, measures for temperature as 888±28°C.

Using DAQ system be programmed to have automatic control and measurement.

Test section

1, Computer control system of United States special control software for Labview experiment, integration 10.2 “LCD scree;

2, Data acquisition systems, LabView programming language is used to program, data acquisition cards United States NI offers

3, Data acquisition system consists of the following parts:

1) 16-bit thermocouple input module

2) 16 bit a/d conversion input module

3) Data input/output module

4) 12 bit a/d conversion output module

5) 4 and 8-slot backplane

6) Labview modules

7) Labview/Ethernet network module

4, Brand testing systems, gas burners, the flame engulfed the burning material, the gas burner is 880±10ºC temperature can be adjusted;

The standard results

1, General standards for flame spread

1) Any part of the roof covering materials (component or Panel) from the test deck in flame or glowing particles blown,

2) Can slide through, split, curved roof covering materials, such as roof deck open,

3) Fire safety rating A: flame spread range is 1.82M,

Fire safety level B: flame spread range is 2.4M,

Rank C fire safety: fire spreading area is 3.9M,

Measured from the edge of the sample spread of flame,

2, General standards for roof combustion,

1) Any part or component of the Panel from the test deck in flames blowing or falling,

2) Parts of the roof deck or a part of a Panel in the roof structure or component in the form of luminous particles disappear,

3) Continue with components or panels of combustion,

Product Display:

DONGGUAN YUYANG INSTRUMENT CO.,LTD is Located in Wanjiang District (Dongguan City, Guangdong Province,China),a famous historical town with prosperous industry and convenient transportation.

We are a high-tech enterprise which is specialized in developing and manufacturing Fire Testing Equipment, Building Material Fire Tester, Wire and Cable Fire Tester, Environmental Test Chamber, Textile Testing Equipment, Toys Testing Equipment and etc.

Decades of research and development strengthen the leading edge of YUYANG in this field, and established as an crucial role in R&D on high quality and high-cost performance of testing equipment. YUYANG’s testing equipment are widely used in various field: scientific institutions, colleges, inspection institutions, auto parts, electronics, electricals, lithium battery, LED, photoelectricity, mobile, plastic and rubber, display, telecommunication, chemical industry, aerospace, building material and product, wire and cable, toys, furniture, textile and fabrix, etc. All YUYANG testing equipment are designed according to international test standards, such as ISO, ASTM, DIN, EN, GB, BS, JIS, ANSI, UL, TAPPI, AATCC, IEC, VDE, CSA,CEN and so on.

DONGGUAN YUYANG INSTRUMENT CO.,LTD looks forward to cooperating with customer all over the world.

If you are interested in any of our products or would like to discuss a custom order. Please feel free to contact us. We are looking forward to forming succesful business with new clients around the world in the near future.

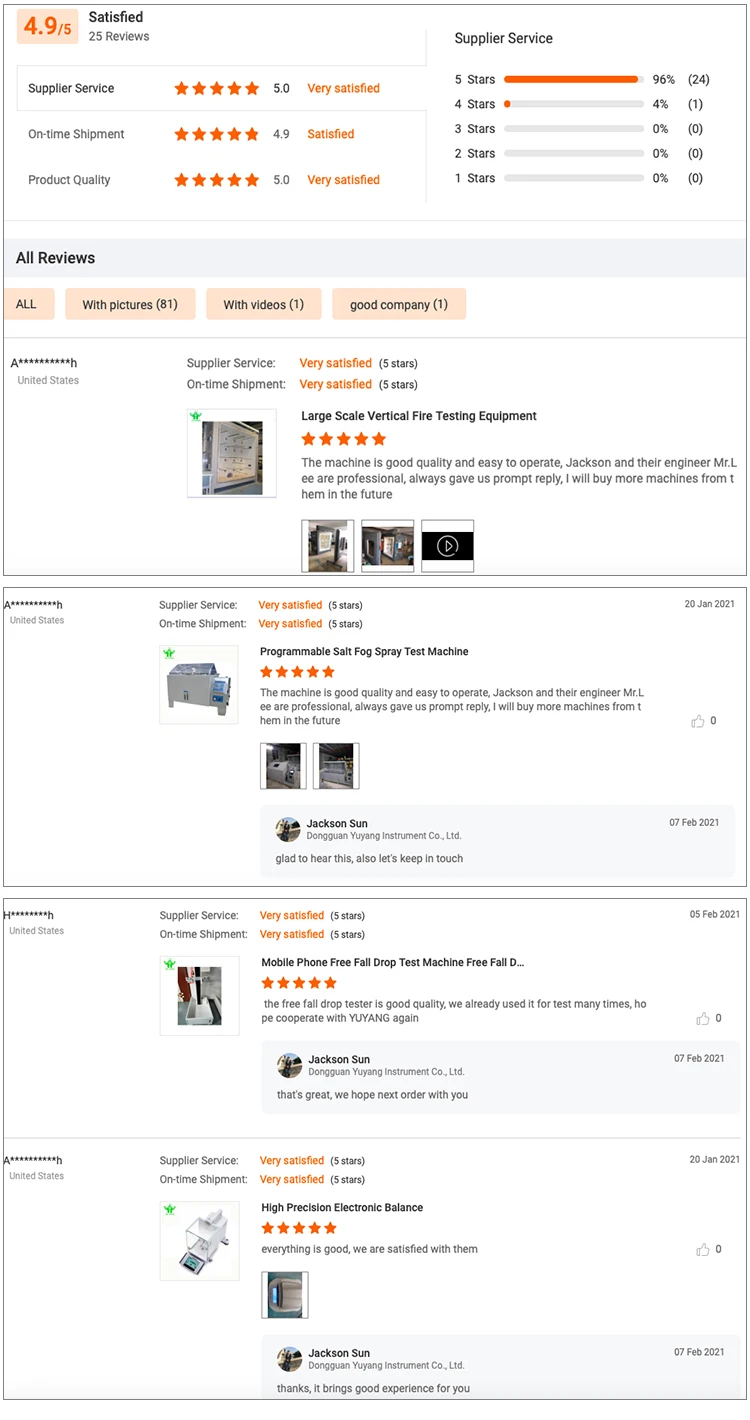

Reviews

There are no reviews yet.