Fertilizer granulator machine is used to process powder materials into different shape granules. In general, fertilizer can be divided into compound(inorganic) fertilizers and organic fertilizers, so fertilizer granulator should be two kinds, NPK fertilizer granulator machine and organic fertilizer granulator machine.

For bio-organic fertilizer granulator, the granulator machine can be disc granulator, new type fertilizer granulator, fertilizer mixing granulator and flat die fertilizer granulator; also for NPK compound fertilizer, the fertilizer granulator machine can be double roller fertilizer granulator, rotary drum granulator and disc type fertilizer granulator. As our experience, disc fertilizer granulator and rotary drum granulator can process both organic and inorganic fertilizer. All these fertilizer granulators from Gate Heavy Industry will be in good working efficiency, they fertilizer granulators will properly granulate the raw materials into required granule size and the granulation rate will be higher than 90% in the fertilizer granulator.

Technical parameter fertilizer double roller granulator machine:

For dry granulation, or no drying granulation, the raw material should be in moisture of 5%-10%, especially under 5%, after granulator granulating the final products will be better. The most suitable machine is double roller fertilizer granulator. One time granulating and the granulation rate will be higher than 93% in this fertilizer granulator machine. Final granule size will be 3-5mm in fertilizer granulator.

|

Model

|

GTG-1T

|

MSJZ-1.5T

|

MSJZ-2T

|

MSJZ-3T

|

|

Capacity

|

1t/h

|

1.5t/h

|

2t/h

|

3t/h

|

|

Grantular diameter

|

3-10mm

|

3-10mm

|

3-10mm

|

3-10mm

|

|

Grantulator strenth

|

6-20N

|

6-20N

|

6-20N

|

6-20N

|

|

Granulation rate

|

>>=90%

|

>>=90%

|

>>=90%

|

>>=90%

|

|

Material Moisture Content

|

2%-9%

|

2%-9%

|

2%-9%

|

2%-9%

|

|

Granulation temperature

|

normal temputure

|

normal temputure

|

normal temputure

|

normal temputure

|

|

Power

|

11kw

|

18.5kw

|

22kw

|

37kw

|

|

Roll skin size

|

150*220mm

|

150*300mm

|

185*300mm

|

300*300mm

|

Technical parameter Fertilizer double roller granulator machine:

Double roller Granulator Machine for Fertilizer is widely used for producing round organic and compound fertilizer granules. With granulator pan’s rotating, granules will be out from small size to large size in the granulator. Disc pan fertilizer granulator is common using granulator machine in fertilizer factory and has a history of good working experience in fertilizer granulator using.

|

Model

|

Disc dia(mm)

|

power(kw)

|

capacity(T/h)

|

|

GTG-800D

|

800

|

1.5

|

0.1-0.2

|

|

GTG-1000D

|

1000

|

1.5

|

0.2-0.3

|

|

GTG-1200D

|

1200

|

1.5

|

0.3-0.5

|

|

GTG-1500D

|

1500

|

3

|

0.5-0.8

|

|

GTG-1800D

|

1800

|

3

|

0.8-1.2

|

|

GTG-2000D

|

2000

|

4

|

1.2-1.5

|

|

GTG-2500D

|

2500

|

7.5

|

1.5-2.0

|

|

GTG-2800D

|

2800

|

11

|

43499

|

|

GTG-3000D

|

3000

|

11

|

43500

|

|

GTG-3600D

|

3600

|

18.5

|

43561

|

Technical parameter Organic fertilizer granulator machine:

Factory Supply Bio Organic Fertilizer Granulator Machine is also called wet fertilizer granulator or stirring tooth granulator. It can granulate a variety of organic matter, especially be able to granulate the coarse fiber material which is difficult to be granulated by normal granulators. The capacity in new type fertilizer granulator will be 1-10 tons per hour.

|

Model

|

GTG-60

|

GTG-80

|

GTG-100

|

|

Power

|

37KW

|

55KW

|

75KW

|

|

Capacity

|

1-2 T/H

|

2-4 T/H

|

5-8 T/H

|

|

Dimension

|

4100*1600*1150mm

|

4250*1850*1300mm

|

4700*2350*1600mm

|

|

Installation Angle

|

2°-2.5°

|

2°-2.5°

|

2°-2.5°

|

|

Inlet Moisture Content

|

20%-40%

|

20%-40%

|

20%-40%

|

|

Inlet Materials Size

|

50mesh

|

50mesh

|

50mesh

|

Technical parameter compound fertilizer granulator machine:

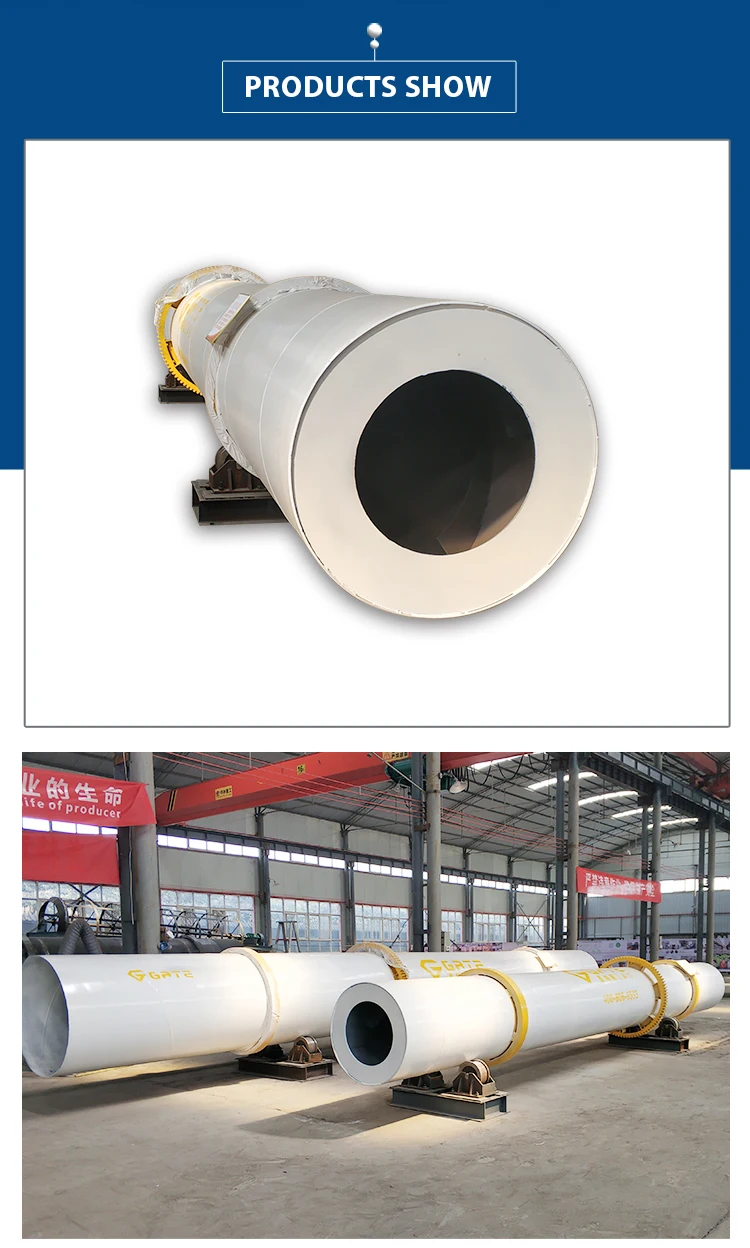

Rotary Drum Granulator fertilizer is a critical granulator machine in large capacity fertilizer production line. It is usually used to process urea and some other compound fertilizers in the granulator machine. The formed fertilizer particles from rotary drum granulator are of 3-4mm in ball shape with no edge.

|

Model

|

Power (kw)

|

Rotary Speed (r/min)

|

Capacity (t/h)

|

|

GTG-1240

|

5.5

|

17

|

1-3

|

|

GTG-1540

|

7.5

|

14

|

3-5

|

|

GTG-1560

|

11

|

11.5

|

5-7

|

|

GTG-1870

|

15

|

11.5

|

7-9

|

|

GTG-2080

|

18.5

|

11

|

8-12

|

|

GTG-2280

|

22

|

10

|

10-15

|

1. What should be prepared on the raw materials before fertilizer granulator granulating ?

everything should start in full preparation, also for fertilizer granulator granulating. The raw materials can not be into fertilizer granulator granulating directly, or it will bring harm to the fertilizer granulator machine and the final granules will be nutrients less.

2. How to make the granules more perfect ?

After fertilizer granulator granulating, most of the granules are still not strength. In order to reach the best quality, will need some other related equipment to help work after fertilizer granulator.

3. How To Establish Chicken Manure Organic Fertilizer Production Line?

the moisture of Chicken manure is around 70%, straw moisture content is 10%, after composting water content of chicken manure can be reduced to 30%. The initial water content adjusted to 50-60% is the best. You can calculate the amount of back fill for chicken, manure is 33%, chicken manure and accessories ratio is 3: 1. According to the local conditions, you can use straw, corn stalks, peanuts and other organic matter as the auxiliary material.

4. How to Start the Production of NPK Compound Fertilizer Production Line?

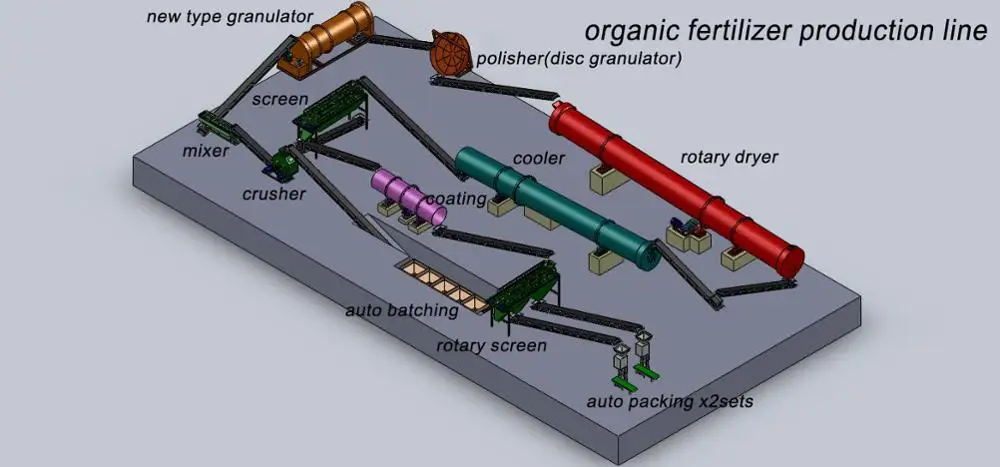

The npk compound fertilizer production line include automatic batching machine, mixer machine, rotary drum granulator or pan/sisc granulator, belt conveyor, rotary dryer, rotary cooler, rotary screen, rotary drum coating machine, automatic packing machine and chain crusher. We provide complete sets of equipment for npk compound fertilizer production and solutions for our esteemed customers!

Reviews

There are no reviews yet.