With Syntec Control System Four processes CNC engraving machine cnc router for caving

| TPR-1325 automatic loading and unloading engraving machine |

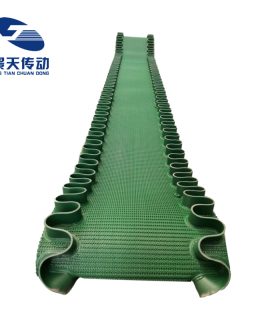

| This TPR-1325 automatic loading and unloading engraving machine has a front lifting platform design and a lifting roller table that makes it easier for the entire board to enter and exit, and is equipped with a board positioning system. Vacuum suction cup design, equipped with universal vacuum suction cup, can quickly control the displacement of the plate, combined with a vacuum regulating valve. The middle section pusher design, the pusher design can quickly push out the completed workpiece, and at the same time absorb the next piece into the processing area for positioning processing. After the belt conveyor, the belt conveyor can quickly output the pushed workpiece to the positioning point, and the speed can be adjusted at will. The dust collecting filter plate on the lower side, when the workpiece is pushed out, the dust collecting filter plate can completely remove the dust of the workpiece. The plate shift detection switch, the front detection switch controls the belt conveying transmission, and the rear detection switch controls the plate to stop transmission. Reduce labor intensity, improve work efficiency, and reduce labor costs. |

| Product details |

| Main parameters |

| Main feature |

|

1. Vacuum adsorption on the table. The whole board can be cut on the wire without sawing again, and the production of molds can be omitted. 2. The high-power air-cooled spindle motor has low noise and high power, ensuring the stability of the equipment for a long time. 3. The XY axis left and right front and rear double limit devices prevent the mechanical collision caused by the design layout exceeding the processing range and avoid the damage of the machine performance. 4. The machine body is seamlessly welded by thick-walled square tubes. After the finite element analysis and design, the machine bed provides a rigid and stable processing platform for the machine tool. All the machine body parts have been tempered and relieved before the machine body is processed, so it is firm and does not deform after long-term use. 5. The machine has fast speed, strong cutting force, can carry out heavy cutting, automatic loading and unloading design, better improve work efficiency and save costs. 6. According to the special needs of customers, various sizes and configurations can be tailored to specific requirements. |

| Sample disply |

|

Suitable for industries such as furniture, home improvement, paint-free doors, woodworking decoration, wooden crafts, cabinet doors, screens, three-dimensional wave panels, advertising, precision instrument shell processing, musical instruments and other industries.

Machinable materials: various wood materials, plastics, organic glass, insulating materials, PVC, acrylic, two-color boards, ABS boards and other non-metallic materials. |

| Machine shipping |

|

1. We use fumigated wooden boxes to transport goods. There is a soft material packaging on the surface of the machine to prevent the machine from being damaged by collision during transportation. 2. You can choose sea transportation according to your needs, see land transportation, and air transportation. We will deliver the goods according to your requirements. |

| Our service |

|

Guarantee: 1. The machines are all brand new genuine parts, and the warranty period is 2 years. Within 24 months of normal use and maintenance, if the machine fails, you will get spare parts for free. 2. Provide 24-hour online after-sales service and provide permanent technical support. 3. Provide machine manuals and simple troubleshooting manuals, and engineers can be sent to the country for on-site maintenance. |

| FAQ |

|

Q1: How to ensure that the machine is suitable for us? We are a machine supplier and can do product testing for free. You can send us sample pictures, and we will provide sample testing for free. In addition, you are welcome to visit our factory and check the machines.

Q2: What should I do if I cannot use the machine after receiving it?

Q3. How to ensure the quality of the machine after placing an order? Q4. What should I do if there is a problem after receiving the machine?

Q5. MQQ? |

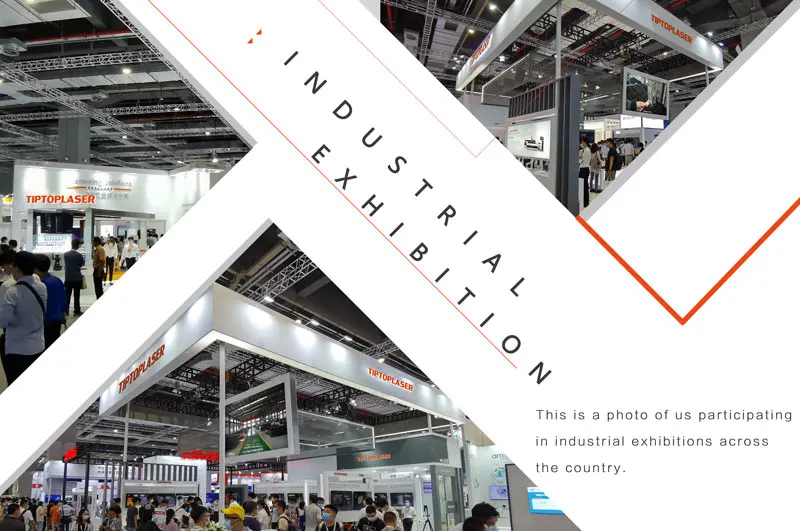

| Company information |

| Shenzhen Tip-Top Manufacture & Trading Co., Ltd is a branch company with engineers and research and development for 16 years. It is a professional manufacturer engaged in the research, development, production, and service of fiber laser marking machine. Fiber cutting machine, fiber marking machine, CNC router, laser engraving machine, laser welding machine, and plasma cutting machine. |

| Contact us |

Reviews

There are no reviews yet.