Wheel Repair Lathe Advantages

1. Cuts wheel up to 27’’.

2. With CE, SGS, ISO, BV certificates.

3. Automatic ruby probe system.

4. Easy Operation.

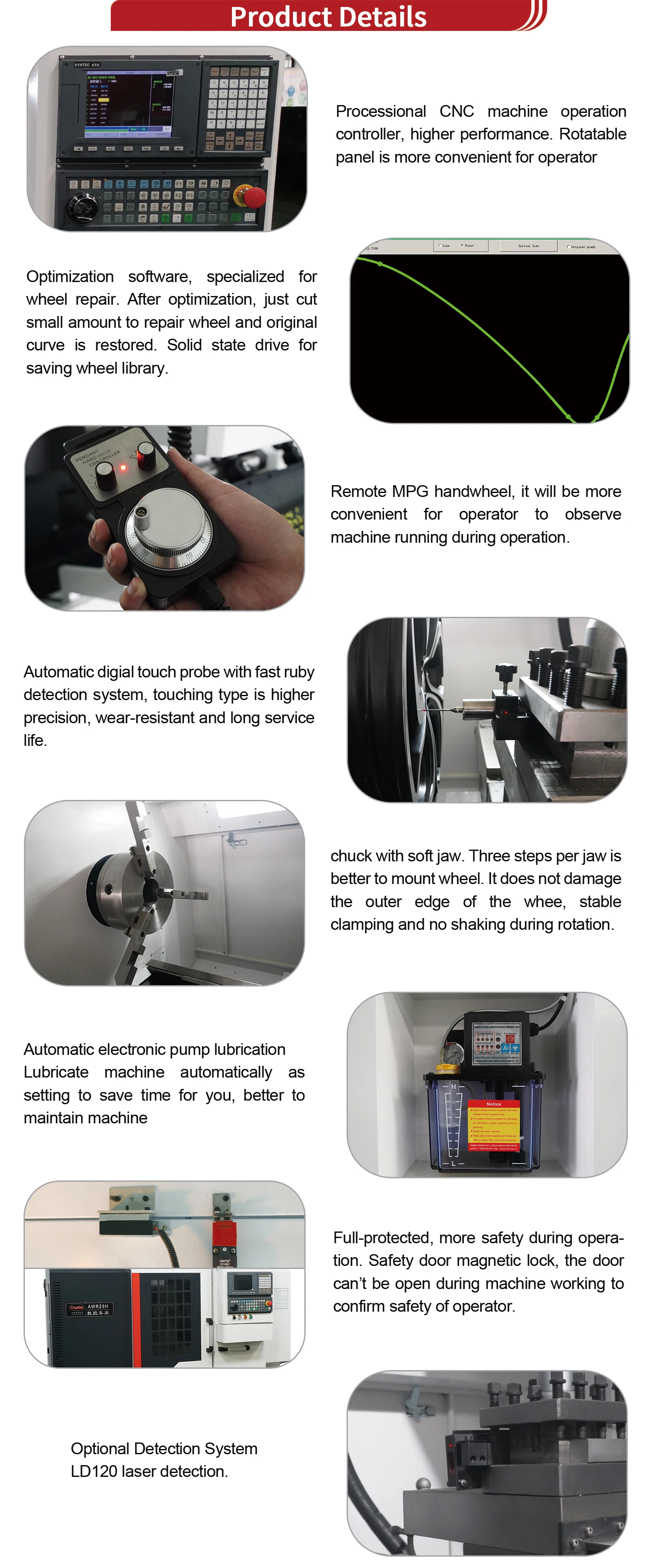

5. Self-developed optimization software.

6. Free Training video and manual.

7. 7×24 hours technology support.

8. 2 USB interface.

9. High efficiency and economic.

10. Two-year warranty.

11. Free factory hand-to-hand training.

12. Agencies in UK, Germany, Poland, Netherlands, Australia etc.

Rim repair machine specifications:

|

Main Technical parameters |

AWR28H |

|

Max. swig over bed(mm)(inch) |

Φ770(30”) |

|

Max. Size of alloy wheel(mm)(inch) |

Φ720(28”) |

|

Adjustable stroke of carrier in X direction(mm) |

100 |

|

Length of the rail |

1300mm |

|

Width of the rail |

300mm |

|

Size of the three-jaw chuck |

12inch |

|

Range of spindle speed |

50-2000rpm |

|

Spindle bore |

Φ82mm |

|

Taper of spindle bore |

1:20(Φ90)

|

|

Max. size of tool post |

25×25mm |

|

Stations of tool carrier |

4 position |

|

Min. setting unit of motor |

(Z) long 0.001mm,(X) cross 0.001mm |

|

Moving speed of post |

(Z) long 8m/min,(X) cross 6m/min |

|

Motor power |

7.5KW |

|

Packing size(length×width×height) |

2140 mm×1600mm×1860mm |

|

Net weight |

2200kgs |

|

Spindle speed control |

Automatic |

|

Cross slide travel |

390mm |

Standard configurations:

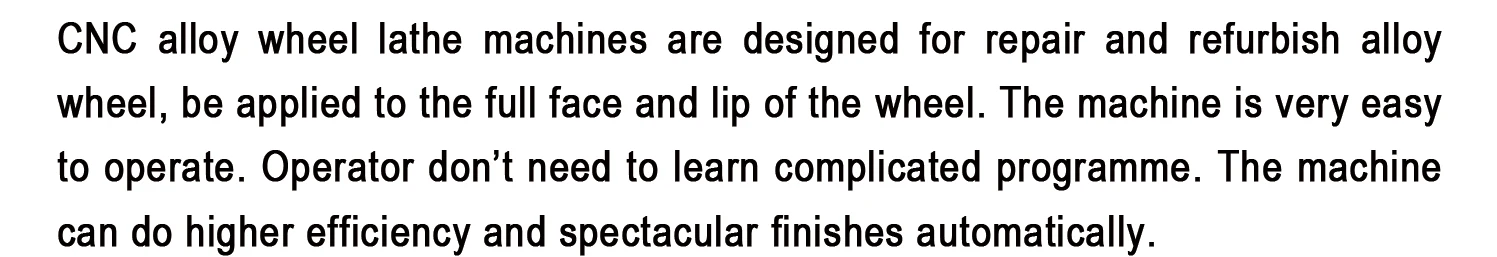

1. SYNTEC CNC system.

2. One probe sensor.

3. Manual chuck with 2 sets of 3-claw (3-steps soft claw).

4. 4 position tool turret.

5. Full enclose protection door.

6. Photoelectric protection switch.

7. Special designed optimization software.

8. English version manual instruction and training video.

9. Automatic lubrication system, cooling system, lighting system.

1.Q:The machine can repair wheel edge?

A:Yes, that’s no problem to repair wheel edge.

2.Q:The machine is easy to learn?

A:Yes, it is very easy to learn. The detailed manual and training video will be supplied

with machine together .

3.Q:Do I need any special software for my PC?

A:We will provide optimization software (It is specifically aimed at wheel repair and

we have independent intellectual property rights).

4.Q:What kind of tool that wheel repair machine use?

A: It is diamond cutting tools.

5.Q:How many time it takes to repair a wheel ?

A:For same model wheels, the first one needs about 10 minutes, because

probing wheel curve will take some time. After first one, the curve will be saved, so

when you repair other wheels as same model, it just takes about 3 minutes.

6.Q:Can we go to your factory and learn how to use the machine?

A:We sincerely welcome you come to our beautiful city. The training is free. It would

be great honor to us.

7.Q:Can you arrange training in our place after we bought your machine?

A:We can arrange oversea training. Buyers will be responsible to the costs.

Reviews

There are no reviews yet.