Products Description

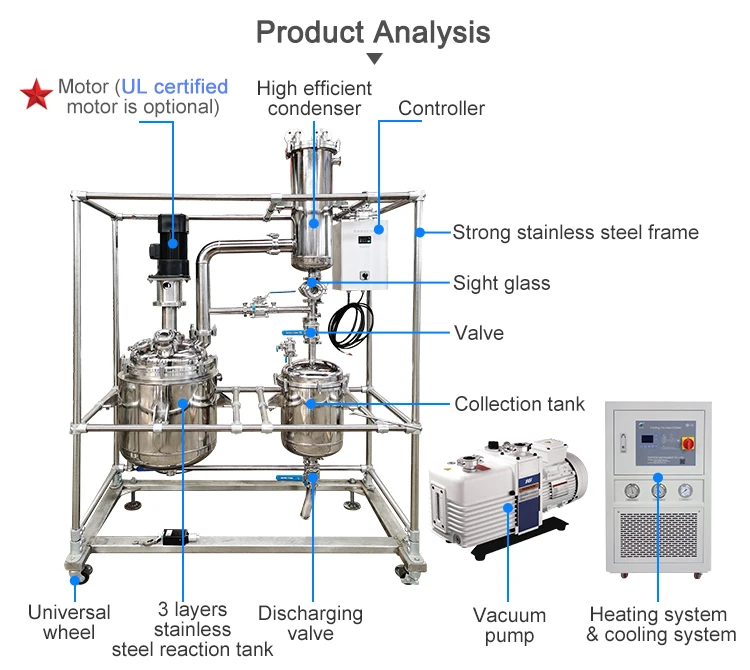

Decarboxylation reactor is to convert CBD-A into CBD, two-pump unit, first remove a large amount of reagents with water ring pump, then use oil pump to remove most of the terpene components, which will greatly improve the distillation efficiency in next process.

|

Model

|

TDC-50L

|

TDC-100L

|

TDC-200L

|

||

|

Stirred reactor

|

Net volume 50L

|

Net volume 100L

|

Net volume 200L

|

||

|

The part in contact with the material is S31603, and the rest is S30408

|

|||||

|

Magnetic drive, static sealing

|

|||||

|

Mixing power 750W, frequency conversion speed regulation

|

Stirring power 1.5KW, frequency conversion speed regulation

|

Stirring power 1.5KW, frequency conversion speed regulation

|

|||

|

The jacket is heated cyclically, with a 40mm heat insulation layer outside the jacket

|

|||||

|

Install pressure gauges and thermometers

|

|||||

|

One feed port, interface KF16, with one ball valve

|

One feed port, interface KF25, with one ball valve

|

One feed port, interface KF25, with one ball valve

|

|||

|

One gas protection port, interface KF16, with one ball valve

|

One gas protection port, interface KF25, with one ball valve

|

One gas protection port, interface KF25, with one ball valve

|

|||

|

Jacket inlet and outlet DN25

|

Jacket inlet and outlet DN25

|

One spare port, interface KF25, with one ball valve. Jacket inlet and outlet DN25

|

|||

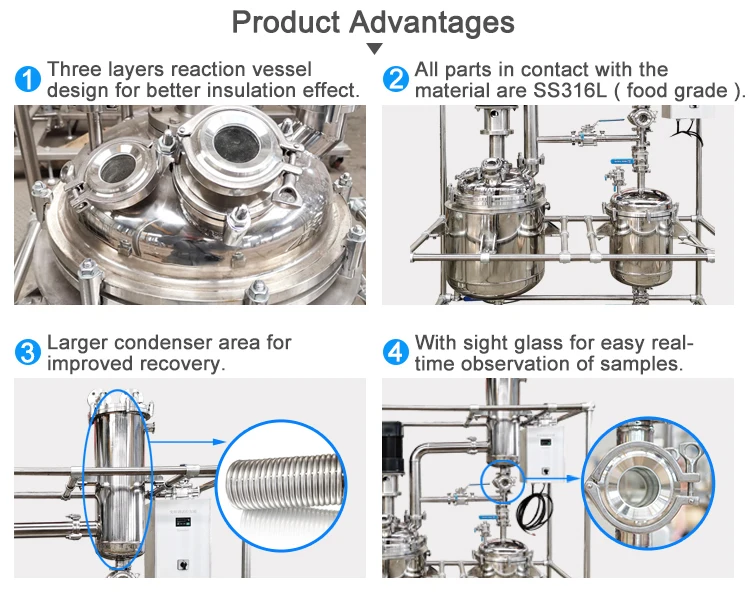

Product advantages

1. The net volume of the stirred tank is 50L, 100L, and 200L, are our top 3 models. Decarboxylation requires precise control of temperature and time, thermal conductivity is very important, we all know that stainless steel has good thermal conductivity. Therefore, when selecting materials for the reactor, we strictly control the quality. The parts in contact with the materials are made of high-quality food grade SS316 stainless steel, and the other parts are high-quality SS304 stainless steel, ensure quickly heat transfer rate.

2. Professional customization of reactor lid with greatest flexibility.

3. Three layers reaction vessel design for better insulation effect, the jacket is heated cyclically, and the jacket also has a 40mm insulation layer.

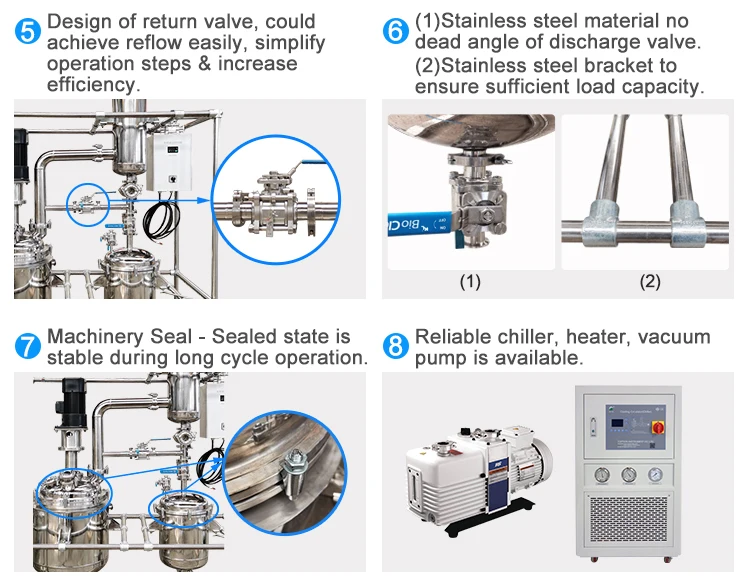

4. Magnetic rotation, static sealing, ensure the sealed state be stable during long cycle operation.

5. Explosion-proof certified Motor.

6. Stainless steel SS316 material larger condenser area for improved recovery.

7. Sight glass design for real-time observation of samples.

8. Reflux design with return valve, could achieve reflow easily, simplify operation steps & increase efficiency.

9. Install pressure gauge and thermometer.

10. Ball valve design, achieve a complete seal within a large pressure & temperature range.

11. Stainless steel material no dead angle of discharge valve.

12. Stainless steel support frame to ensure sufficient load capacity.

13. Reliable chiller, heater, vacuum pump is available.

2. Professional customization of reactor lid with greatest flexibility.

3. Three layers reaction vessel design for better insulation effect, the jacket is heated cyclically, and the jacket also has a 40mm insulation layer.

4. Magnetic rotation, static sealing, ensure the sealed state be stable during long cycle operation.

5. Explosion-proof certified Motor.

6. Stainless steel SS316 material larger condenser area for improved recovery.

7. Sight glass design for real-time observation of samples.

8. Reflux design with return valve, could achieve reflow easily, simplify operation steps & increase efficiency.

9. Install pressure gauge and thermometer.

10. Ball valve design, achieve a complete seal within a large pressure & temperature range.

11. Stainless steel material no dead angle of discharge valve.

12. Stainless steel support frame to ensure sufficient load capacity.

13. Reliable chiller, heater, vacuum pump is available.

Application

Packing and feedback

Certificate and Exhibition

ISO | CE | RoHS | TUV | BV manufacturer certification

1. Professional customize based on more than 15 years manufacturing experience.

2. ISO | CE | RoHS | TUV | BV certification reliable quality guarantee.

3. Factory directly sale for competitive price, help you save cost.

4. Fast delivery within 7days of hotsale types.

5. Professional service team, provice 24h 7days online service.

1. Professional customize based on more than 15 years manufacturing experience.

2. ISO | CE | RoHS | TUV | BV certification reliable quality guarantee.

3. Factory directly sale for competitive price, help you save cost.

4. Fast delivery within 7days of hotsale types.

5. Professional service team, provice 24h 7days online service.

Our Factory

Reviews

There are no reviews yet.