Specification

|

Model

|

TC-250

|

TC-320

|

TC-350

|

|

Film Width

|

Max.250mm

|

Max.320mm

|

Max.350mm

|

|

Bag Length

|

65-280mm

|

65-280mm

|

65-330mm

|

|

Bag Width

|

30-110mm

|

30-150mm

|

50-160mm

|

|

Product Height

|

Max.40mm

|

Max.40mm

|

Max.45mm

|

|

Packing Speed

|

40-230 bags/min

|

40-230 bags/min

|

40-230 bags/min

|

|

Power Specification

|

220V,50/60Hz,2.4KW

|

220V,50/60Hz,2.4KW

|

220V,50/60Hz,2.4KW

|

|

Machine Size

|

3770*670*1450mm

|

3770*720*1450mm

|

4020*770*1450mm

|

|

Machine Weight

|

500KG

|

500KG

|

500KG

|

Product Description

Main Features:

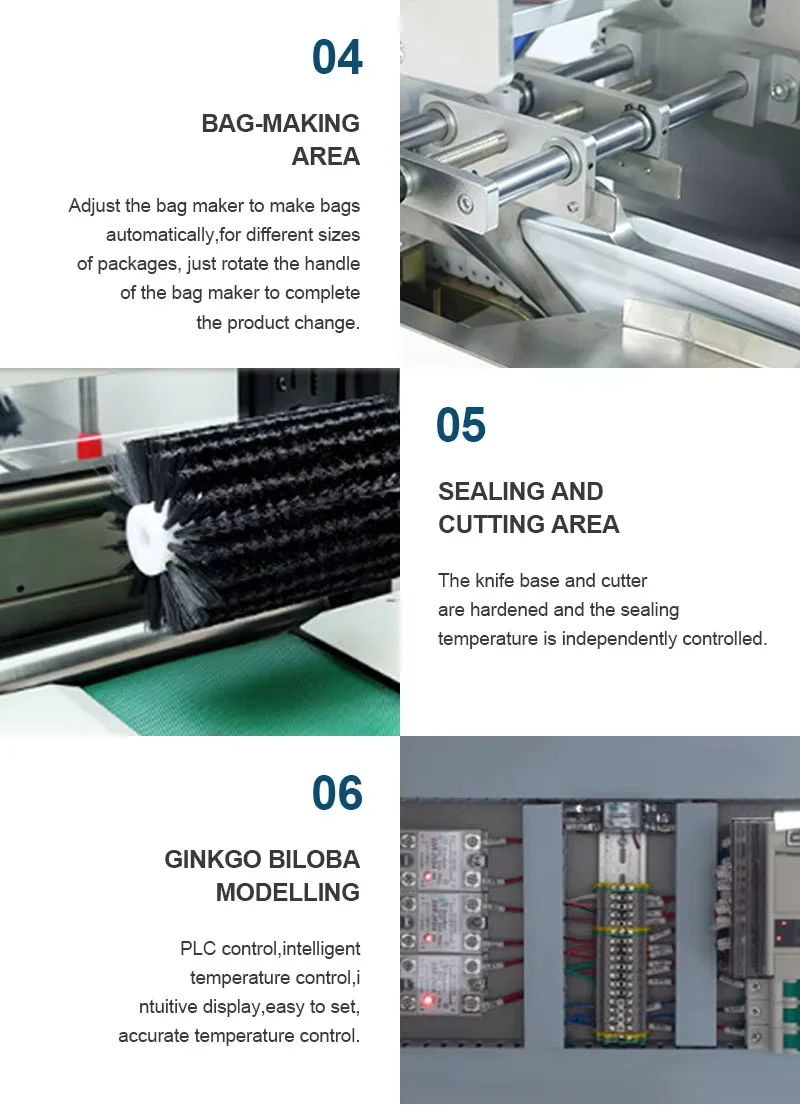

1) Dual frequency conversion control,bag length can be set and cut in one step ,saving time and film.

2) High sensitivity photoelectric eye color tracing,numerical input of cutting sealing position for estra accuracy.

3) Positioned stop function ,without sticking knife or wasting film.

4) Simple driving system,reliable working ,convenient maintenance.

5) All control is realized through software ,easy for function adjusting and technical upgrade .

Product Application:

1) Dual frequency conversion control,bag length can be set and cut in one step ,saving time and film.

2) High sensitivity photoelectric eye color tracing,numerical input of cutting sealing position for estra accuracy.

3) Positioned stop function ,without sticking knife or wasting film.

4) Simple driving system,reliable working ,convenient maintenance.

5) All control is realized through software ,easy for function adjusting and technical upgrade .

Product Application:

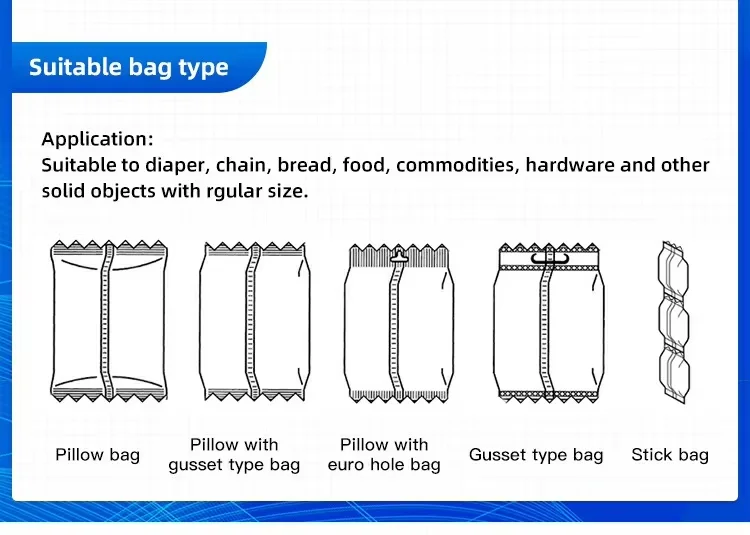

Can be applied to:food(snack bar,bread,cookies,ice lolly cake,chocolate,) Plastic(cutlery,tray,) hardware,Soap,sponge,tissue,cardetc.

packaging various kinds of regular objects.

packaging various kinds of regular objects.

Features:

1. The latest design in 2023, leading the industry trend!

2. Break through traditional technology and achieve high-precision material position control!

3. The new intelligent operating system can store 99 product parameters, making the operation simpler and more convenient!

4. Highly sensitive slck electric eye tracking system ensures more accurate packaging results!

5. The machine operates stably and the product is resistant to cutting. Once the product is cut, the machine will automatically stop running, providing reliable protection for your production line!

6. The shell is made of PE polymer material, which is lightweight andportable, making it convenient for you to carry and use!

7. High quality and low price, it can meet your needs without putting too much pressure on your budget!

8. Innovative design makes your products unique in the market!

9. High-precision performance adds quality assurance to your products!

10. Comprehensive upgrade to create efficient and intelligent packaging solutions for you

Reviews

There are no reviews yet.