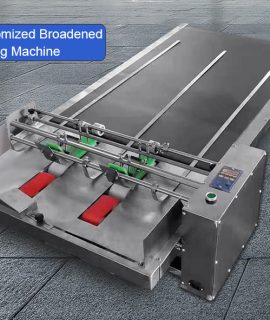

Hot sale epoxy floor equipment

Product Applications

Suitable for the recovery of new surface roughness,surface hair,old epoxy renovation process.Equipped with different thicknesses of diamond tool,can realize all kinds of floor grinding,such as hardening,terrazzo,carborundum floor wear-resisting,all kinds of concrete.Fine knife tools for floor surface of fine grinding processing,but also on the middle tier of epoxy floor leveling process.But since the research ground height.

|

Model |

OK-600C |

|

Weight |

165KG |

|

Power of main motor |

5.5KW |

|

Voltage |

380V |

|

Current |

8A |

|

Working Voltag |

380V |

|

Working width |

560mm |

|

Working depth |

1-3mm |

|

Water tank Capacity |

36L |

|

Speed |

900r/min |

|

Grinding head |

6 pieces |

|

Grinding disc |

2 pieces |

|

Disc diameter |

300mm |

|

Accessory weight |

20kg/3block |

|

Noise |

low than 60dba |

Instructions

1. Remove the machine from the box and lay it flat.

2. Remove the motor cover and check the belt tightness. If the belt is loose, pressed down the handle to tilt the chassis, chassis four fixing screws relax, tightness and sheet metal hand tightened following the push bolt until it reaches the specified, then the shell is installed.

3. Chassis tilt, exposed triangular discs, the grinding head is installed on a triangular plate is fixed, then the outer skirt to the appropriate location.

4. Put the machine flat, ensure three diamond grinding heads of the triangle plate and rear wheels in a plane.

5. Plug in power supply, rotating switch starting the machine. If the dust is out, then the switch is rotated to the middle stop stat, the rotation goes to the opposite direction and then run normally.

6. After the machine starts, according to the ground strength and processing effect to choose the appropriate speed uniform propulsion.

7. Mechanical operation about 10 minutes can be stopped mechanically, then reverse to the dust on the filter removed, in order to achieve the better effect of the dust. Running 50 minutes will mechanical stop, turn on the vacuum cleaner, silo dust clean.

8. In operation, there is any abnormal phenomenon please stop the machine immediately, then check the end can be re used.

Operation method and notice

The operator must be familiar with the general structure and performance of the equipment, and shall not exceed the performance of the equipment. Parts and the volume of the abrasive tool shall not exceed 90% of the volume of the hopper. After the power is switched on, of idling, should run smoothly, no abnormal noise. Otherwise, should stop check. The work-piece must be removed before the work-piece is ground to remove oil and dirt. In machining process must be based on the work-piece grinding conditions to add the amount of abrasive and control water. When the work is finished, cut off power, cleaning equipment, good equipment maintenance work. Before starting the safe operation, check the fastening screws, check the motor shaft and other rotation is flexible. Equipment in operation, found that the exception should be parking.

![WQ60H91{8M1U_6A2OG~J]$K.png](http://sc01.alicdn.com/kf/HTB16amCbhrvK1RjSsze761ObFXaZ/224712457/HTB16amCbhrvK1RjSsze761ObFXaZ.png)

![Z]3RQH31HSWAK]WE{SKBT%2.png](http://sc02.alicdn.com/kf/HTB1fR1vbizxK1Rjy1zk761HrVXax/224712457/HTB1fR1vbizxK1Rjy1zk761HrVXax.png)

Q: Are u the manufacturer ?

A: We mainly produce excavators, truck cranes, and at the same time have a professional sales team, industry and trade integration.

Q: What’s your MOQ of this term?

A: 1 set.

Q: How long is your warranty?

A: Guarantee for 12 mounths starting from products arriving the destination port.

Q: Could you stick customers brand on the products?

A: Of course, we welcome the OEM orders.

Q: What’s your delivery time?

A: Delivery timely about 7 days after receiving the deposit.

Reviews

There are no reviews yet.