bio organic compost mixer machine

Introduction of Groove Type seed fermentation tank

our organic fertilizer groove type seed fermentation tank is the most widely-used as aerobic fermentation compost machine and compost turning equipment. The organic fertilizer waste compost turner machine includes walking fermentation groove, walking track, turning teeth, power-pick device and other parts. The working portion of the compost windrow turner machine adopts advanced roller drive. There are adjustable type and non-adjustable type for choice. The groove type compost windrow turner is widely used for dealing with animal manure, household garbage, sludge, crop stalks and other organic wastes, and also can be used in feed fermentation.

specifications of Mobile Type seed fermentation tank

| Model | Motor(kw) | Work Speed |

Non Load Speed (m/h) |

Fermentation Tank Size |

Dimension(mm) | stirring Height |

| (m/h) | (mm) | (mm) | ||||

| FJC3000 |

15+1.1 +3+1.1 |

60 | 100 | 300×1550 | 3670×2120×2540 | 800-1500 |

| FJC4000 |

18.5+1.1 +3+1.1 |

60 | 100 | 400×1550 | 4670×2120×2540 | 800-1500 |

| FJC5000 |

18.5+1.1 +3+1.1 |

60 | 100 | 500×1550 | 6670×2120×2540 | 800-1500 |

Introduction of Mobile Type seed fermentation tank

Self Propelled Mobile Type Compost Turner for Fertilizer is the main machine in the organic fertilizer production. It adopts crawler belt drive design which only needs one person to drive and the operation is very easy.

When windrow compost turner for organic fertilizer starts to work, it straddles the strip-type compost heap and the rotary cutter shafts under the rack stir and mix the material. The operation can be completed not only in the open area but also in the workshop and greenhouse. One of the cow dung compost fertilizer turner machine ’s technical breakthroughs is to integrate the crushing function at the later stage of the material fermentation. With the continuous dehydration of the material, the cutter shafts can effectively crush the caking formed during the fertilizer fermentation. Thus the production does not need to equip an additional crusher, the crushing efficiency is greatly improved and the cost is largely reduced.

Specifications of Mobile Type seed fermentation tank

| Model | Zk-2000 | ZK-2300 | ZK-2600 |

| Stack Width | 2000mm | 2300mm | 2600mm |

| Stack Height | 600-800mm | 800-1200mm | 1000-1300mm |

| Stack Spacing | 0.5-0.8m | 0.8-1m | 0.8-1m |

|

Maximum Materials Size |

250mm | 250mm | 250mm |

| Power | 30hp | 51/62hp | 116hp |

|

Maximum Rotate Speed |

2200r/min | 2200r/min | 2200r/min |

| Running speed |

50m/min Forward 3 gear, back 1 gear |

50m/min Forward 3 gear, back 1 gear |

50m/min Forward 3 gear, back 1 gear |

| Capacity | 300-400m3/h | 500-700m3/h | 1000-1200m3/h |

1) Why Choose GATE Technology To Be Your Professional Supplier of Fertilizer Machine?

HENAN GATE HEAVY INDUSTRY MACHINERY TECHNOLOGY CO.,LTD is a leading and professional manufacturer of fertilizer machine and whole fertilizer production line in China. We are expertise in manufacturing high quality equipment for fertilizer production. We believe in “Great Achievements Through Excellence!” As for management principles, we insist on High Quality, Great Mission and Extraordinary Values.

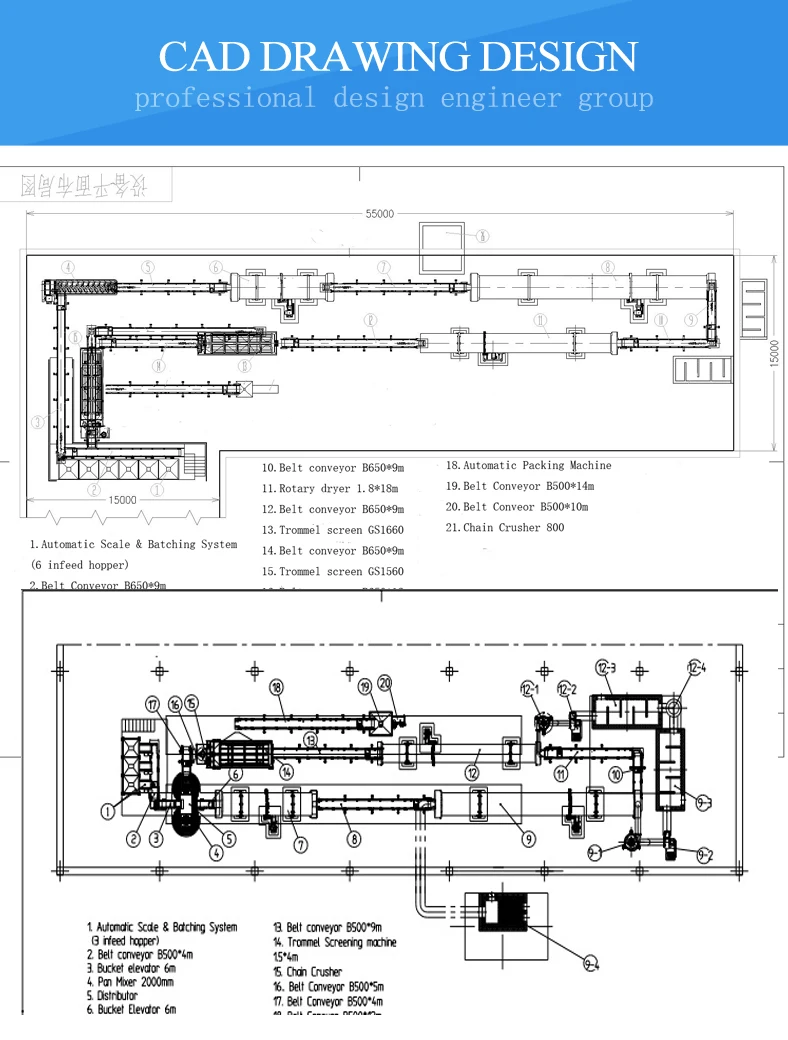

2) What We Can Provide for Our Customers?

We can provide whole line of service, from technical consultancy, CAD drawing design, factory design, equipment production, shipment, and dispatch professional engineers to guide for installation and commissioning service, training your workers and technical stuff. Also, we have sufficient stock of spare parts, we can provide the spare parts at very fast speed and lowest cost.

3) What’s the Production Period of the Fertilizer Machine?

for single fertilizer machine, our production time is 7 days;and for whole fertilizer production line, our production time is no more than 30 days.

4) What’s the Quality Guarantee and Certifications?

all of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 18 months after shipment date.

5) Will Gate Technology Dispatch Engineers for Installation and Training Work?

Gate will dispatch engineers to help customers for the installation and commissioing work of the machines, and provide training service for all of our customers.

Reviews

There are no reviews yet.