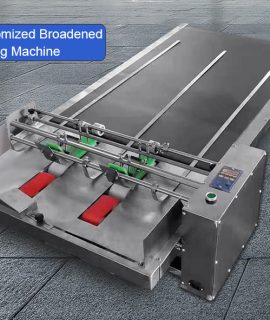

Characteristic:

This machine is equipped with nl-5557 high cycle spark protection system, with high sensitivity

3. The oscillation frequency of high frequency fuse meets the international industrial band standard

4. The high cycle current is regulated by electric control, and the VC meter shows that it is more convenient to adjust;

5. In order to improve the safety of employees and save manpower, the machine is equipped with an automatic feeding table. ;

6. Equipped with high cycle frequency stabilizer and high frequency shielding device to reduce high frequency interference to low level;

7. Automatic over-current protection system can increase the service life of vacuum tube and protect the mold;

8. Avoid radio interference and frequency drift

9. The main difference between the left and right slide table fuse and the integrated fuse is: good flatness and convenient disassembly

Advantage:

2. Pressurization mode of synchronous fuse: air oil pressure type and pure oil pressure type are available.

3. The pure oil pressure fuse adopts two-way automatic slide table to push the mold back and forth or continuously, with accurate positioning of ± 20um.

4. High sensitivity nl5557 spark arrestor is used in automatic slide hydraulic fuse to effectively prevent mold damage.

5. The cutting pressure of high-power fuse is 1-50 tons, which can be customized, with stable and reliable output and strong structure.

|

Model

|

CH-15KW-HTRD

|

|

Output Power

|

15KW

|

|

Voltage

|

380V 3P 50/60HZ

|

|

Input Power

|

25KVA

|

|

Oscillation Frequency

|

27.12MHZ

|

|

Oscillation Tube

|

8T85RB

|

|

Anti-Spark System

|

NL-5557

|

|

Max Pressure

|

30TON

|

|

Gap of Electrode

|

200MM

|

|

Size of Mould Holder

|

400*600MM

|

|

Machine Size

|

2400*1800*2250mm

|

|

Machine Size

|

1500KG

|

Purpose:

Reviews

There are no reviews yet.